Vacuum End Effectors

Unlock the full power of autonomous material handling. Vacuum end effectors deliver the pneumatic muscle AGVs need to grab, lift, and maneuver loads—from hefty boxes to delicate parts—with pinpoint precision and speed.

Core Concepts

Vacuum Generation

The heart of the system. Venturi ejectors (using compressed air) or electric vacuum pumps create the pressure differential that powers the lift.

Suction Cups

The hands-on link between robot and object. Pick from flat, bellows, or oval shapes in materials like silicone or NBR to suit any surface texture or temperature.

Payload Capacity

Figured from vacuum level and total suction area. In AGVs, bake in safety factors (2.5x to 4x) to avoid drops during accel or braking.

Air Saving Valves

A game-changer for mobile robots. These setups kill air use once vacuum's locked in, stretching AGV battery life big-time on long holds.

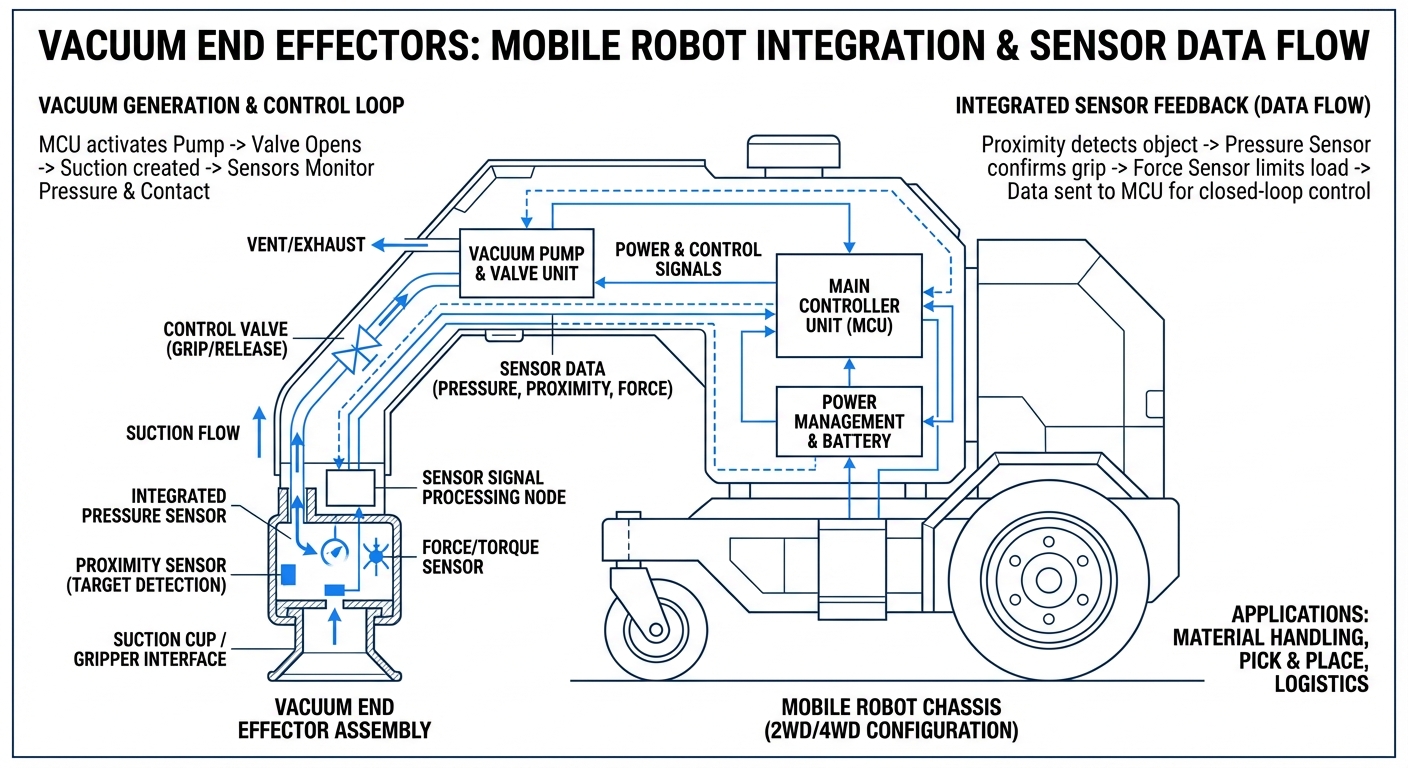

Sensors & Feedback

Pressure switches and vacuum sensors feed live data to the controller—greenlighting moves only on solid grips and sounding alarms on leaks.

Foam Grippers

Cups alternative for porous or uneven stuff. Big foam pads with check valves let AGVs snag jar layers, gappy pallets, or rough lumber with ease.

How It Works

Vacuum end effectors don't technically "suck"—they just evacuate air between gripper and workpiece, dropping pressure below atmosphere.

Atmospheric pressure does the heavy lifting, shoving the object onto the suction cup. AGVs pull this off via facility air lines (for tethered setups) or—more commonly—onboard electric pumps juiced by the robot's battery.

Advanced setups use "zone gripping," where smart valves auto-seal uncovered suction ports. One big gripper now tackles varying box sizes, no tweaks or pressure drops needed.

Real-World Applications

Warehouse Palletizing

AGVs with large-area vacuum grippers stack cardboard boxes on pallets effortlessly. They handle recycled cardboard's bumps and hold firm through fast spins.

Bin Picking & Fulfillment

In e-commerce fulfillment, mobile manipulators wield small, nimble vacuum cups to pluck items like cosmetics, books, or blister packs from messy bins for order assembly.

Sheet Metal Handling

Manufacturing AMRs use specialized high-friction vacuum cups to shuttle oily sheet metal between stamping presses—zero slippage like you'd get with magnets.

Glass & Solar Panel Transport

Fragile, non-porous materials demand finesse. Vacuum grippers deliver a mark-free, gentle hold that spreads stress evenly, dodging cracks in transit.

Frequently Asked Questions

What is the difference between a Venturi generator and an electric vacuum pump?

Venturi generators blast compressed air through a nozzle for vacuum (pneumatic)—super quick and lightweight, but you need an air line. Electric pumps run straight off power (AGV-friendly) and shine for long holds with better efficiency, though they're heavier and slower to spin up.

How do vacuum grippers handle porous materials like cardboard?

Porous materials leak air right through the object, killing vacuum. Fight back with high-flow generators to offset leaks, plus cups featuring soft sealing lips or foam for airtight contact.

What happens if the AGV loses power while holding an object?

Safety first. Most industrial vacuum grippers pack a "normally closed" check valve or retention tank. Power dies? It traps the vacuum, holding the load for minutes to hours—plenty of time for safe recovery or reboot.

Does using a vacuum gripper drain the AGV's battery significantly?

It can if unmanaged, but modern "air-saving circuits" fix that. Hit target vacuum? Pump idles or shuts off, firing back only on pressure drops. Battery-friendly for mobile robotics.

Can a single vacuum tool handle boxes of different sizes?

Absolutely—with area grippers or foam pads packing check valves. They auto-block uncovered suction points (open to air), letting a big gripper snag small boxes without pressure bleed.

When should you go with vacuum grippers instead of mechanical claws?

Pick vacuum for grabbing boxes from the top (like palletizing), smooth flat surfaces (glass or metal sheets), or tight spaces where you can only approach from one side. Mechanical grippers work better for oddly shaped objects that need wrapping around or in super dirty, dusty environments that could clog up vacuum filters.

How often do suction cups need to be replaced?

Suction cups wear out eventually. Their lifespan hinges on how rough the materials are (think concrete chewing them up versus gentle glass) and how many pick-and-place cycles they endure. In fast-paced AGV logistics, basic rubber cups might need swapping every few months, but sturdy polyurethane ones can keep going way longer.

Can vacuum grippers work in dusty environments?

Absolutely, but you need solid filtration. Dust clogs vacuum generators or messes with the seal. Put inline filters between the cups and pump. In really dusty spots like handling cement bags, go for specialized filters with auto-cleaning blow-off.

What's the "Safety Factor" and why does it need to be higher for AGVs?

The safety factor is your theoretical max lift force divided by the load's actual weight. Stationary arms often get by with 2:1. For AGVs, aim for 4:1 since they're zipping around, accelerating, and braking—those dynamic forces (like inertia) could shake the load right off if the grip isn't bombproof.

How do I size the vacuum cups correctly?

Size them based on the object's weight, surface type, and available grab area. Figure required force (Weight × Safety Factor), then match cup area to your vacuum level (typically -0.6 to -0.8 bar). Spread the cups to cradle the center of gravity and avoid peeling edges.

Are bellows cups better than flat cups?

It depends on your setup. Flat cups give rock-solid stability and precise positioning—perfect for speedy moves. Bellows cups flex like springs, handling height differences and bumpy surfaces, especially if your AGV can't nail a perfect vertical approach.