Ultrasonic Distance Sensors

Give your AGVs 'sound vision' for foolproof collision avoidance, docking, and spotting clear obstacles cameras miss.

Core Concepts

Time of Flight (ToF)

It times how long a sound pulse takes to hit something and echo back, turning that into spot-on distance reads.

Blind Zone

Every ultrasonic sensor has a blind spot up close—usually 2-20cm away. Objects in this "blind zone" can't be detected accurately because the transducer is still ringing from the pulse.

Beam Angle

The sound wave spreads out in a cone, typically 15° to 60° wide. A wider beam spots more obstacles but makes it tougher for the robot to nail down their exact angle.

Acoustic Crosstalk

When multiple robots are working nearby, their sensors can pick up each other's signals and interfere. Frequency hopping or timed firing sequences help dodge this issue.

Material Reflection

Hard, flat surfaces reflect sound waves perfectly. Soft stuff like foam or angled surfaces can absorb or deflect them, so you might need to bump up the sensitivity.

Temperature Drift

The speed of sound shifts with air temperature. That's why modern sensors pack built-in thermometers to make real-time corrections for pinpoint accuracy.

How It Works

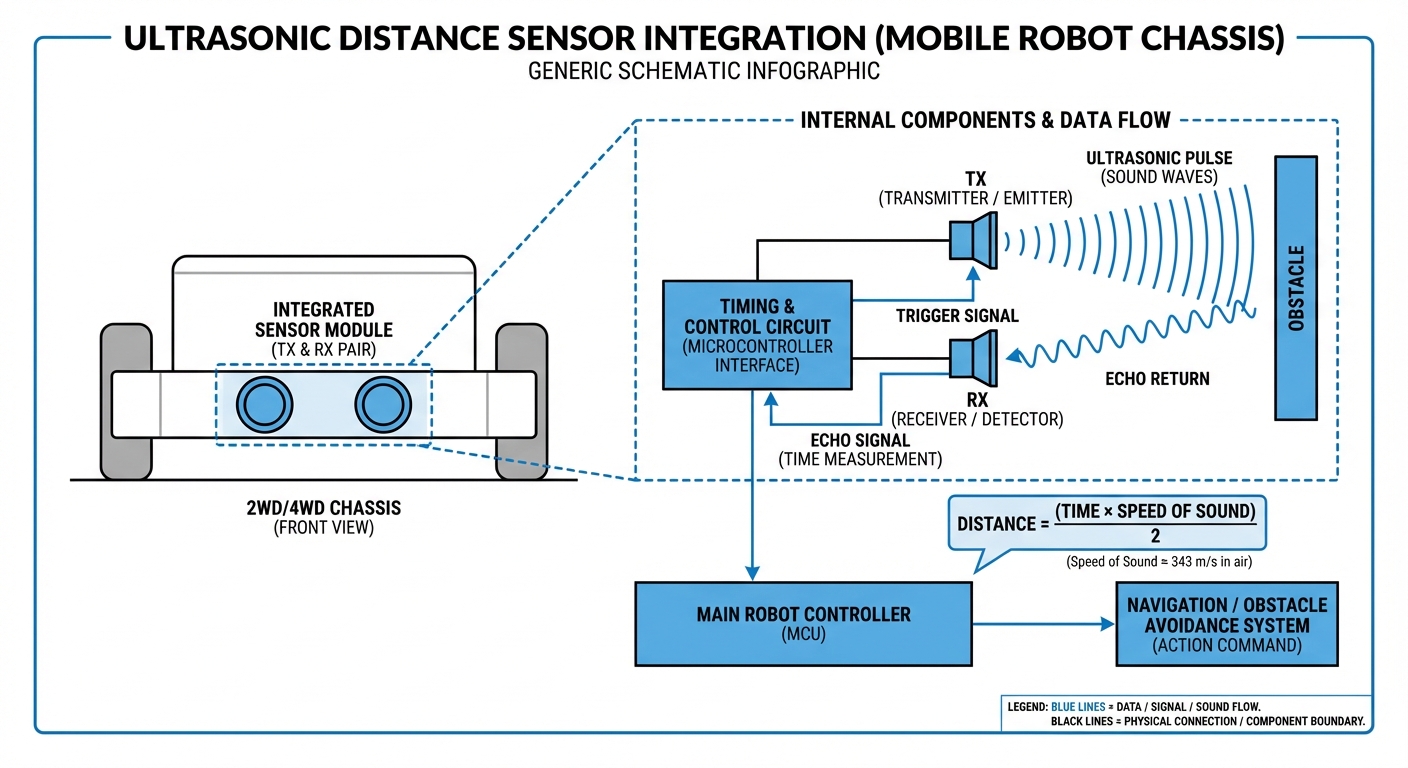

Ultrasonic sensors work like bat echolocation. A piezoelectric transducer vibrates to shoot out a high-frequency sound pulse (usually 40kHz, silent to human ears) into the surroundings.

When the wave hits an obstacle, it bounces back as an echo. The sensor flips to "listening" mode right after sending, and the onboard controller times the round trip ($t$) down to microseconds.

Using the speed of sound in air (about 343 m/s at 20°C), distance comes from this formula: $$Distance = (Time \times SpeedOfSound) / 2$$. Divide by 2 because the sound travels to the object and back.

Real-World Applications

Safety Bumper & Collision Avoidance

They're a staple in logistics. Ultrasonic sensors act like a "virtual bumper" for AGVs, spotting people or forklifts in the path and triggering emergency stops—totally independent of the main nav system.

Transparent Object Detection

Unlike LiDAR or cameras, ultrasonic waves bounce perfectly off clear glass, plastic barriers, or shiny metal, making them essential in today's glass-heavy buildings.

Precision Docking Alignment

For charging or loading docks, robots need to creep in slowly. Ultrasonic sensors deliver precise short-range data to line up contacts within millimeters.

Liquid Level Monitoring

In robots hauling fluids, downward-facing ultrasonics check tank levels without contact, preventing sloshes or overflows on the move.

Frequently Asked Questions

What’s the typical range for ultrasonic sensors on AGVs?

Most industrial ones for robotics work from 20cm (minimum) up to 4-6 meters. Longer-range options exist, but accuracy drops off sharply past 5 meters as the waves weaken.

How do ultrasonic sensors compare to LiDAR?

LiDAR uses light for sharper resolution and longer range—great for mapping. Ultrasonics use sound: lower res but way cheaper, and they catch glass or water surfaces that LiDAR might ignore.

Can ultrasonic sensors detect soft objects?

It can be tricky. Soft materials like foam, thick fabrics, or fur soak up sound instead of bouncing it back, leading to shorter range or misses. Calibration or pairing with cameras helps.

What happens if I have multiple robots in the same area?

That's "crosstalk." If Robot A’s pulse reaches Robot B, B gets a bogus distance reading. Fix it with sequenced triggers or unique frequencies per robot.

Are these sensors effective outdoors?

They handle outdoors, but wind, humidity, and wild temps mess with sound speed and accuracy. Go for IP67 waterproofing and software tweaks for the environment.

What is the "Blind Zone" and how do we handle it?

It’s the dead zone right in front (say, 0-20cm) where the sensor’s still vibrating from transmitting. Robots deal with it by recessing the sensor or masking it in software.

How fast can the sensor update (Refresh Rate)?

Refresh rates are capped by sound speed. For 3 meters, round-trip’s ~20ms, so max theory is 50Hz—but real-world is 10-20Hz to let echoes fade.

Why is the beam angle important for navigation?

Wide beams cover lots for safety but suck at pinpointing location. Narrow ones excel at precise mapping but might skip skinny things like table legs.

Does noise from the factory floor affect the sensor?

Usually no. Factory noise is low-frequency hums or bangs, while ultrasonics run at 40kHz+. But air leaks from pneumatics can throw ultrasonic interference.

What is the typical power consumption?

Super efficient—typically 20-50mA. Perfect for battery AGVs watching every watt.

How reliable are they for wall following?

Rock-solid reliable. They nail perpendicular distances to walls, so basic PID loops keep robots at exact spacing using ultrasonic feedback.

Do I need to clean the sensors?

Yep. Dust, oil, or mud buildup dulls the transducer, cutting range. Wipe gently with a cloth in gritty spots.