T-Slot Aluminum Extrusions

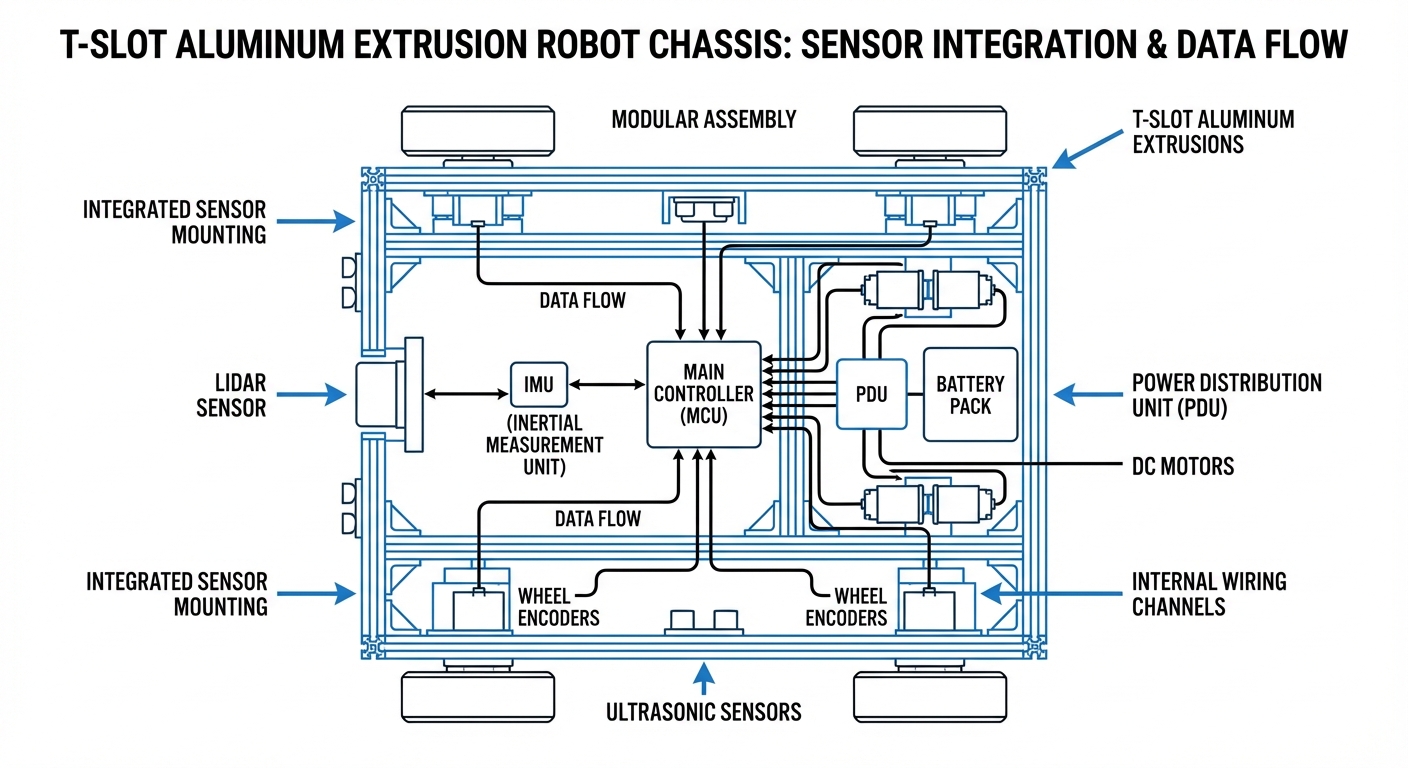

The go-to modular frame for today's mobile robots, perfect for quick prototyping and scaling up fleets. T-slot framing delivers a lightweight yet super-strong chassis, letting you endlessly adjust sensors and actuators without any welding.

Core Concepts

Modular Framing

Nicknamed 'industrial Lego,' T-slots let you build, take apart, and tweak robots using just basic hand tools—making design changes a breeze.

Metric Profiles

Standard sizes like the 2020, 3030, and 4040 series set exact millimeter dimensions for the cross-sections, so you can nail load calculations and ensure parts fit perfectly every time.

T-Nut Fastening

Specialized nuts glide into the channel slots and lock tight when you tighten them, creating rock-solid friction joints anywhere along the profile.

High Strength-to-Weight

The smart cross-section design maximizes stiffness while keeping weight low—key for squeezing more runtime out of batteries in autonomous mobile robots.

Corner Bracketing

Connection plates, gussets, and blind joints give you flexible ways to join profiles, balancing looks, cost, and rock-solid strength.

Integrated Cabling

The slots double as handy cable channels for wiring harnesses, keeping your robot's exterior sleek and shielding wires from snags in busy warehouses.

How It Works: The Mechanics

T-slot aluminum extrusions start with heated aluminum pushed through a die to form that signature T-channel shape on all sides. In robotics, this setup means 'infinite positioning'—slide components to the exact spot you need for perfect sensor alignment or balance tweaks, unlike fixed drilled holes.

It all comes down to compression. Tighten a screw into a T-nut inside the channel, and it spins 90 degrees to grip the T-lip's underside, forming a super-strong friction bond. For the shakes and jolts of AGVs, add spring-loaded nuts or thread-locker to keep everything from loosening up.

Most profiles sport an anodized finish (clear or black) for a tough, rust-proof surface. But since anodizing blocks electricity, you'll need special grounding tricks if you're using the chassis as your robot's electrical ground plane.

Real-World Applications

AGV Chassis Fabrication

It's the main skeleton for small- to medium-payload AGVs. Those channels make it a snap to mount drive wheels, suspension, and battery trays—no custom machining needed.

Sensor Masts & Towers

Vertical extrusions are perfect for LiDAR, stereo cameras, and lights. You can tweak the height on the fly during tests to nail the best view for your robot.

Warehouse Docking Stations

Stationary charging docks and guides use beefier 40-series profiles to shrug off bumps from docking robots while holding the contact plates.

End-Effector Frameworks

For mobile manipulators, T-slots build the upper frame to hold conveyor belts, robot arms, or shelf lifters right on top of the mobile base.

Frequently Asked Questions

What series of extrusion works best for a standard warehouse AGV?

For most indoor warehouse AGVs hauling under 100kg, go with the **2020 (20mm)** or **3030 (30mm)** metric series. 2020 keeps things light for sensors and top frames, while 3030 provides a sturdy spine for the drivetrain and chassis. Heavy-duty tuggers often bump up to 4040 or 4545.

How does T-slot framing cope with a robot's vibrations?

Bolted joints hate vibes, but for mobile robots, fight back with **thread-locking fluid (Loctite)** on every screw, spring washers, and regular torque checks. For key chassis spots, gusset plates beat basic blind joints for way better stiffness and shake resistance.

Is aluminum extrusion tough enough for heavy battery packs?

Absolutely, if you spread the load right. Aluminum 6063-T5 packs serious strength. Watch for beam sag though—support big batteries like LiFePO4 with cross-members often, or pick thicker-walled profiles.

Can I weld T-slot aluminum for a permanent bond?

Technically yes, but it's rare and not recommended. Welding kills the anodizing, warps the straightness, and undoes the whole modular vibe. Need something super-permanent and rigid? Custom welded steel is usually smarter.

How do I ground an anodized aluminum robot chassis electrically?

Anodizing insulates everything. To ground it, pierce the layer at connections with star washers that bite through, or sand the spot for your ground lug.

What is the difference between T-nuts and Hammer nuts?

**T-nuts** usually slide in from the profile ends before assembly. **Hammer nuts (or roll-in nuts)** drop right into any slot along the way and twist to lock—ideal for adding sensors to a built robot.

How precise do my cuts need to be for a square chassis?

Spot-on accuracy matters for straight driving. Even 1mm off can make differential-drive bots crab sideways. Get pre-cut lengths from pros with industrial saws, or use a top miter saw with an aluminum blade and stop-block setup.

Is T-slot framing suitable for outdoor agricultural robots?

Yes, aluminum doesn't rust easily. But steel bolts and T-nuts can. Outdoors? Grab stainless or zinc-plated hardware, and slot covers to block dirt and water.

What's the cost showdown between T-slot and welded steel?

T-slot aluminum costs more upfront than basic steel tube. But add in labor for cutting, welding, grinding, and painting steel—T-slot wins for prototypes and small runs thanks to lightning-fast assembly.

Can I use T-slots for linear motion on the robot?

You bet. V-slot versions are made for wheels rolling right in the channel. Standard T-slots? Mount linear rails or plastic sliders in the slot—great for lifts on warehouse AMRs.

How do I skin the robot body with this frame?

Grab panel mounting blocks to snap in acrylic, poly, or metal sheets flush into the slots. It gives a pro finish that shields electronics from dust and meddlers.