SPI Communication Protocol

Unlock precise control and lightning-fast data exchange in your Autonomous Guided Vehicles (AGVs). The Serial Peripheral Interface (SPI) delivers the synchronous, full-duplex communication that's key for hooking up high-performance sensors and motor controllers in tight robotic setups.

Core Concepts

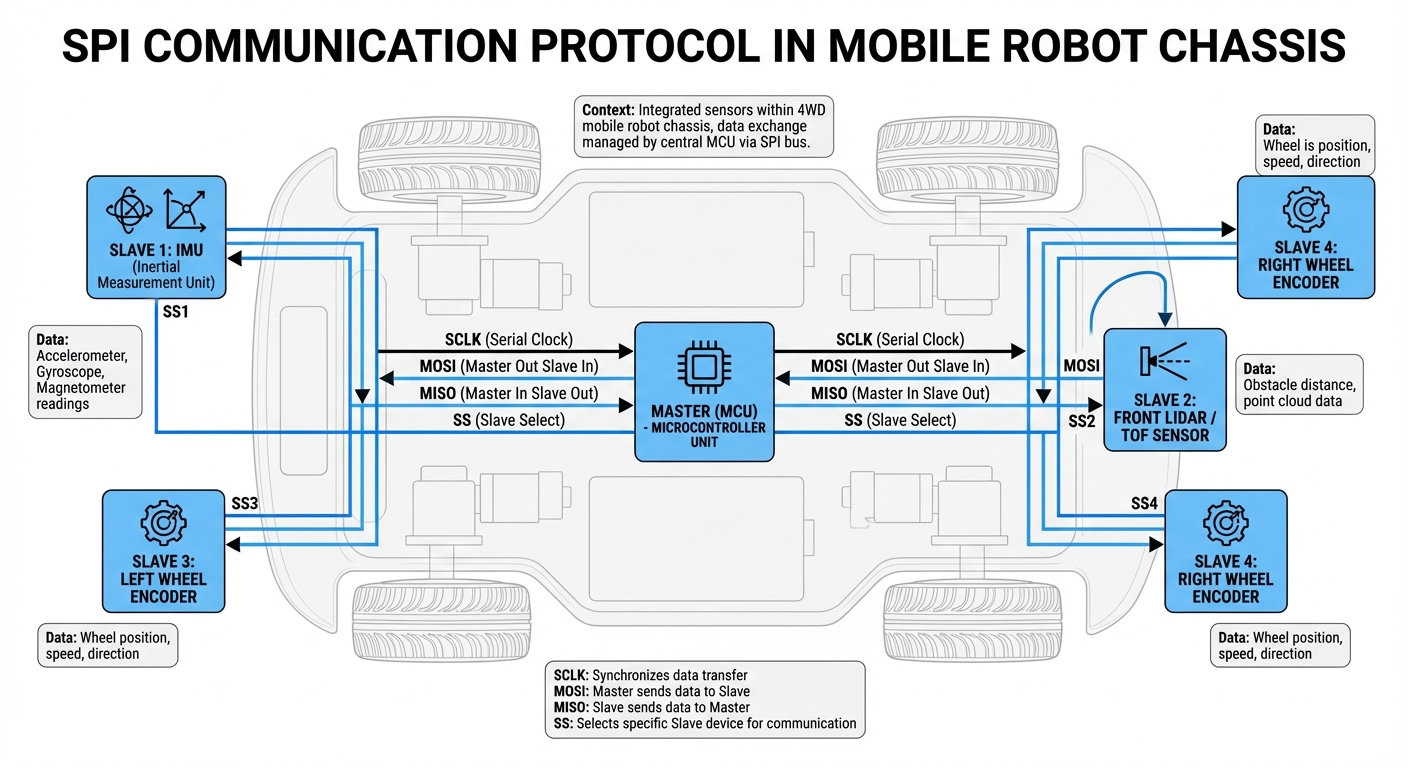

Master-Slave Architecture

SPI runs with a single master (usually the robot's main ECU) calling the shots for multiple slave devices like sensors and drivers.

Full Duplex Data

Unlike I2C, SPI sends and receives data at the same time, basically doubling throughput for those make-or-break navigation tasks.

Synchronous Clock

The master pumps out a clock signal (SCLK) for spot-on timing sync, skipping the hassle of start/stop bits.

High Throughput

Hitting speeds over 10 Mbps, SPI's perfect for bandwidth hogs like small displays or quick-logging SD cards.

Chip Select (CS)

Hardware addressing through Chip Select lines means fast switching between peripherals—no fiddly software needed.

Short-Range Robustness

Built for on-PCB chats, it cuts interference in the crammed electronics bays of mobile robots.

How It Works

SPI uses a four-wire bus to link the AGV's central microcontroller (Master) with its peripherals (Slaves). That separate data lines setup is what makes SPI so speedy.

The four distinct lines are: , which dictates the transfer speed; , carrying commands from the robot to the device; , returning sensor data to the controller; and , which activates a specific device.

In robotics, this lets your navigation controller command a motor driver to speed up (via MOSI) while grabbing the precise wheel encoder position (via MISO) in the very same clock cycle. That zero-latency swap is vital for keeping AGVs glued to their magnetic or SLAM paths.

Real-World Applications

Inertial Measurement Units (IMUs)

High-speed gyro and accelerometer data needs reading thousands of times a second for self-balancing bots or tight AGV turns. SPI manages it no sweat.

High-Resolution Motor Encoders

For pinpoint positioning in warehouse logistics, motor encoders shoot over detailed position data packets via SPI for sub-millimeter precision.

Onboard Diagnostic Displays

TFT or OLED screens on AMRs for human-machine interfaces (HMI) lean on SPI to zip-refresh graphics and status updates.

Black Box Data Logging

Dumping telemetry to SD cards for after-run analysis demands the steady high write speeds SPI brings—beats sluggish protocols like I2C.

Frequently Asked Questions

SPI vs. I2C: Which is better for robotics?

SPI shines for high-speed, short-haul comms where throughput counts, like IMUs or displays. I2C's great for lots of simple sensors over fewer wires when speed's not key. For AGV motion control, SPI's full-duplex edge usually wins out.

What is the maximum distance for SPI communication?

SPI's a 'single-ended' protocol for on-board use, reliable up to 10-20cm. For AGVs with external sensor cables, add differential signaling buffers (like RS-422 transceivers) to stretch range and fight noise.

How many slave devices can I hook to one master?

Theoretically, it's down to how many GPIO pins your microcontroller has free for Chip Select (CS) lines. Daisy-chaining works, but the usual star setup needs a dedicated wire per device, so it's not as scalable as I2C for tons of gadgets.

What happens if the clock signal (SCLK) fails?

Since SPI's synchronous, a busted or noisy SCLK line kills comms right away or garbles data. No async fallback like UART; the slave just hangs waiting for clocks, triggering a timeout in the master's software.

Is SPI hot-swappable for modular robot parts?

Generally, no. Standard SPI skips hot-swap features, and plugging in powered devices can spark electrical glitches or latch-ups. For modular AGV payloads, use isolation buffers or hot-plug-friendly connectors.

Does SPI have built-in error checking?

No, SPI's a bare-bones data protocol without built-in parity or checksums (like CRC). In tough robotics apps, add software checksums or validation bytes for data reliability amid industrial noise.

What are SPI Modes (0, 1, 2, 3) and why do they matter?

SPI modes control clock polarity (idle high or low) and phase (sampling on rising or falling edge). If your AGV's master controller and sensor don't match modes, they'll garble the data bits. Always double-check your sensor's datasheet to sync with the master's setup.

Can I use 3-wire SPI instead of 4-wire?

Yep, some devices do 3-wire SPI, merging MOSI and MISO into one bi-directional line. Perfect for trimming PCB space and cable weight on mini drones or robots, though it ditches full-duplex and cuts max throughput in half.

How do I troubleshoot SPI noise on an AGV?

Kick off by dialing down the clock speed—higher frequencies grab more noise from motor drivers. Cut ground loops, keep SPI lines short, and toss in series termination resistors (33-50 ohms) to tame reflections on PCB traces.

What is daisy-chaining in SPI?

Daisy-chaining hooks one slave's MISO to the next's MOSI, letting multiple devices share a single Chip Select. It simplifies wiring a ton but adds latency, since commands have to snake through every device before kicking in.

Is SPI power-efficient for battery-operated robots?

SPI sips power nicely—no pull-up resistors sucking current like I2C—and it's dead simple in hardware. That said, speedy clock toggling burns dynamic power, so idle the bus (stop the clock) when you're not sending data.