Soft Robotics Actuators

We're shaking up mobile robotics with flexible, adaptable systems that blend bio-inspired softness with pinpoint mechanical accuracy. See how soft actuation makes safe human-robot teamwork possible and handles all sorts of tasks for the next wave of AGVs.

Core Concepts

Mechanical Compliance

Unlike stiff rigid links, soft actuators give way on contact. This built-in flexibility serves as a natural cushion, safeguarding both your AGV's gear and the fragile items it's picking up.

Fluidic Elastomers

Most soft actuators are Fluidic Elastomer Actuators (FEAs), powered by air or fluid pressure that inflates internal chambers for bending, twisting, or straight-line movement.

Infinite Degrees of Freedom

Soft materials offer theoretically endless degrees of freedom (DoF), letting them smoothly wrap around odd shapes without needing fancy sensors.

Material Intelligence

The 'brain' is baked right into the body. By crafting smart internal structures, you shift the actuation smarts to how the material naturally responds.

Energy Efficiency

Once it's puffed up or shaped to grab something, many soft actuators hold that grip with zero ongoing power (thanks to passive locking), which really stretches your AGV's battery life.

Safe Interaction

Soft skins and actuators wipe out pinch points and crash risks, perfect for collaborative mobile robots (AMRs) weaving through busy human workspaces.

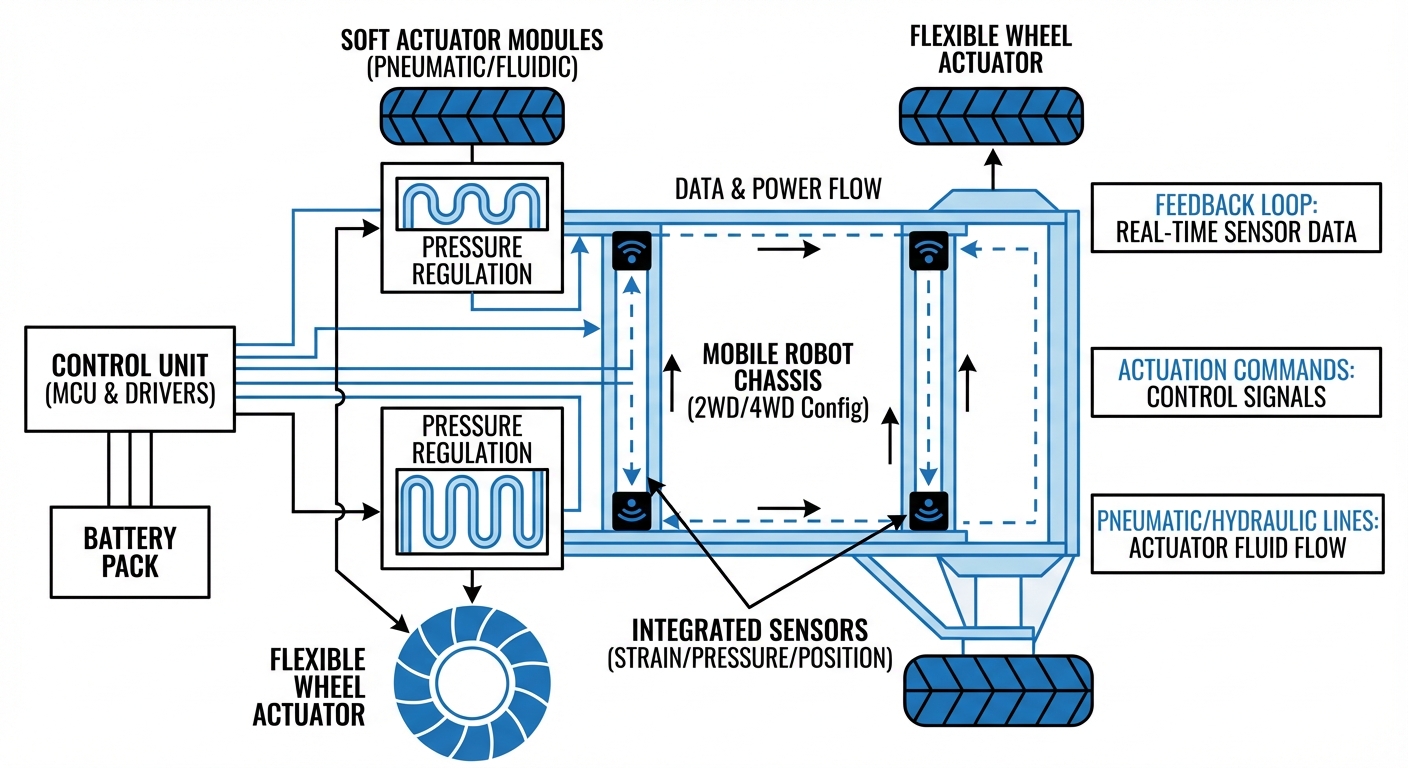

How It Works: Fluidic Actuation

At the core of most soft robotics for logistics is pneumatic inflation. These actuators are made from stretchy elastomers (think silicone) with hollow chambers or channels inside.

Pump compressed air into those channels, and the chambers swell. Add a strain-limiting layer on one side (something that won't stretch), and it bends the whole thing around obstacles—creating curl motions just like human fingers.

For AGVs, you'll need a compact onboard pneumatic setup: a mini compressor, valve array, and pressure regulator. The controls tweak air pressure for the right stiffness or grip strength, so one end-effector can delicately lift a feather or heft a heavy box.

Real-World Applications

Mixed-SKU E-commerce Fulfillment

AGVs with soft grippers can grab all kinds of stuff on their own—from round cosmetics to boxed electronics—without swapping tools. The actuator molds right to the object's shape, cutting down on tricky vision work.

Food & Agriculture Automation

Mobile harvesting bots use soft actuators to pluck fruits and veggies bruise-free. In food processing, soft AGVs manage baked goods and raw ingredients in super-clean sanitary setups.

Healthcare Logistics

Hospital delivery robots rely on soft bumpers and gentle grippers to shuttle lab samples, meds, and meals. Their safety-first design keeps patients and staff safe in tight hallways.

Fragile Component Assembly

In manufacturing, mobile manipulators use soft tips for glass, wafers, or shiny surfaces. The give lets them do press-fits and insertions without smashing pricey parts.

Frequently Asked Questions

What differentiates soft actuators from traditional rigid grippers?

Traditional grippers demand spot-on positioning and force sensors to avoid squashing things, often needing custom fingers per shape. Soft actuators just deform to match the object (that's the compliance magic), spreading force evenly and tackling huge variety without constant recoding.

How are soft actuators powered on a mobile AGV?

Most soft actuators run on pneumatics. On an AGV, that means a tidy onboard system: mini air compressor, small pressure tank, and solenoid valves tied to the robot's ECU. Electric versions (like shape memory alloys) exist but aren't as common for heavy-duty grabs.

What are the payload limitations compared to rigid systems?

Generally, soft actuators have a lower payload-to-weight ratio than rigid clamps. While rigid ones hoist hundreds of kilos, typical soft grippers manage 100g to 5kg. But beefed-up designs with jamming tech can handle way heavier loads.

Are soft robotics durable enough for 24/7 industrial use?

Today's industrial silicones and elastomers last for millions of cycles. The big worry is punctures from sharp stuff, but lots of grippers now use self-healing materials or modular 'fingers' for quick, cheap swaps without ditching the whole unit.

Does the compression system drain the AGV battery quickly?

Pneumatic setups can guzzle energy if the compressor's always humming. Smart ones use holding valves to trap the air after gripping, letting the compressor chill. This zero-energy 'passive hold' matches electric grippers for long hauls.

How precise is the positioning with soft actuators?

Soft actuators aren't as precise as rigid servos—the material's bendy nature is nonlinear. Skip them for micron-precise insertions. They shine in forgiving pick-and-place jobs where a solid grip matters more than perfect alignment.

Can soft actuators handle wet or chemical environments?

Absolutely, that's a huge win. Silicones are waterproof and chemically neutral by nature. They're perfect for wash-down food lines or chemical handling, where metal rust or electrical glitches would doom regular grippers.

How do I control soft actuators with ROS (Robot Operating System)?

Control usually happens through digital I/O or serial links to the pneumatic controller. In ROS, treat the gripper like a simple binary (open/close) or continuous (pressure) joint. Packages like `ros_control` hook up the valves, using pressure sensors for closed-loop feedback.

What is "variable stiffness" in soft robotics?

Variable stiffness lets an actuator flip from soft and compliant to rigid. A popular way is 'granular jamming'—suck air out of a particle-filled bag to lock it solid. Your AGV can slip a soft gripper into a tight spot, then stiffen it for max torque.

Can I add soft grippers to my current AGV fleet?

Definitely—retrofitting is super common. Most makers offer standard ISO plates (like ISO 9409-1). The trickiest bit is squeezing in the pneumatic box (about shoebox-sized) and running air lines up the arm or mast.

How does temperature affect performance?

Extreme cold makes elastomers stiff and brittle, while heat softens them up or weakens structure. But industrial silicones handle -20°C to +80°C reliably. For freezer warehouses, grab low-temp specialty blends.

What is the cost comparison to mechanical grippers?

Soft grippers often match or beat the price of fancy multi-finger rigid hands. The starter kit (controller + gripper) might cost like a solid 2-finger electric one, but you save big on programming and custom fixtures for varied products.