SCARA Robots

Unlock blazing precision for your mobile fleet. SCARA (Selective Compliance Assembly Robot Arm) tech blends rock-solid vertical strength with horizontal flex, making it perfect for mobile setups that need lightning-fast pick-and-place in busy spaces.

Core Concepts

Selective Compliance

That's the hallmark of SCARA. It's stiff in the Z-axis (up-down) for heavy loads but compliant in X-Y, so it can tweak for misaligned holes during insertions.

4-Axis Freedom

Unlike 6-axis arms, SCARAs stick to 4 degrees of freedom: X, Y, Z, and rotation (Theta). This keeps things simple, speeding up cycles and programming for flat-surface jobs.

High-Speed Operation

Thanks to their joint setup and lighter moving parts, SCARAs hit higher speeds and accelerations than full articulated arms—crucial for high-volume mobile fulfillment.

Repeatability

SCARAs boast killer repeatability, often 0.01mm to 0.05mm. Ideal when your AGV pulls up to a precise docking station and the arm takes over.

Mobile Integration

Mount a SCARA on an AMR (Autonomous Mobile Robot), and you've got a 'Mobile Manipulator.' Suddenly, its reach spans the whole factory floor, not just one spot.

Compact Footprint

The cylindrical workspace keeps things compact—vital for squeezing through narrow warehouse aisles without the arm sticking out hazardously.

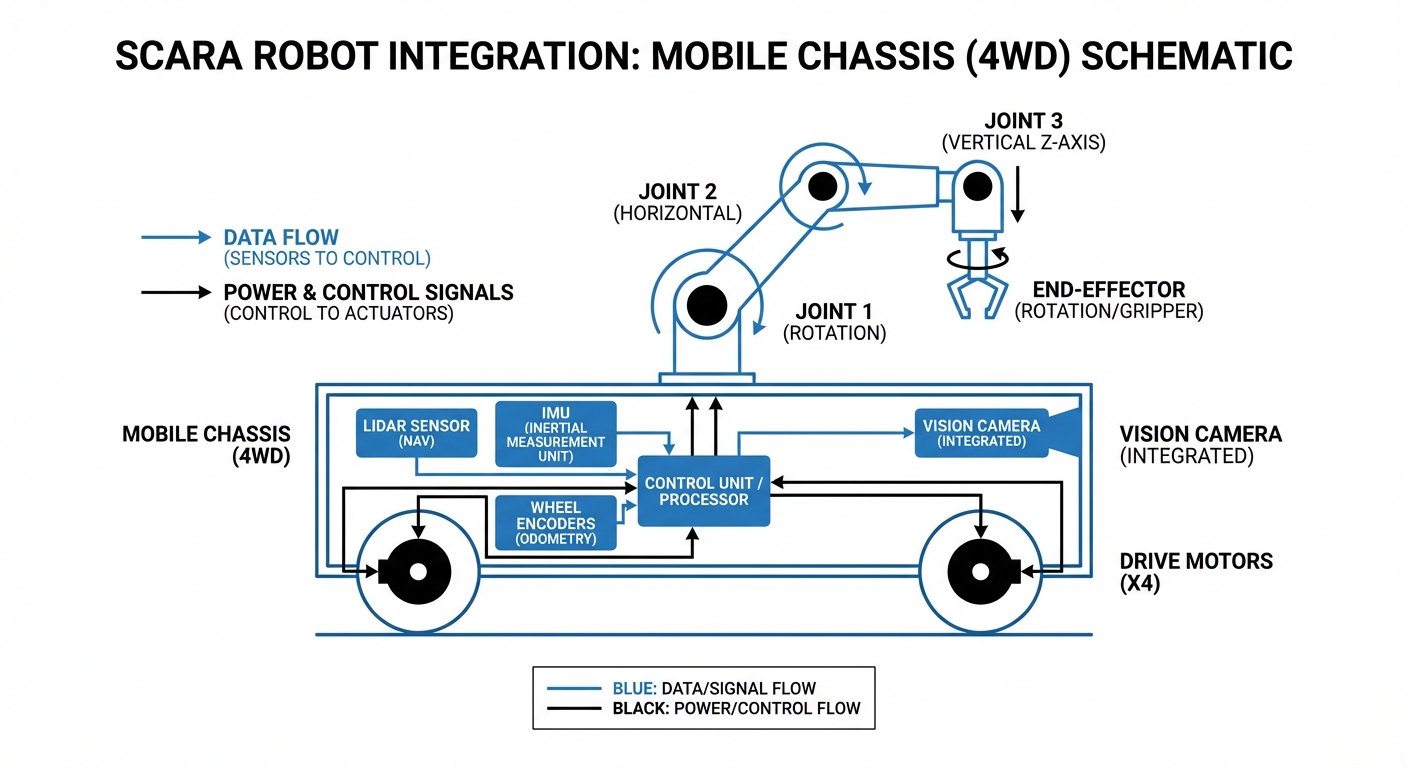

How It Works

SCARA's design features two parallel rotary joints for horizontal give, plus a linear one for up-down. It apes the human arm: extend, retract, with a solid shoulder-to-elbow link.

On an AMR, the SCARA sits atop the deck. The base handles big moves around the facility, while the arm nails the fine, precise interactions with inventory.

With that rigid vertical axis, they crush vertical loads—like pressing parts into boards or stacking trays—better than comparable articulated arms. The stiffness means quicker settling after the AGV halts.

Technical Highlight:

Real-World Applications

Mobile Lab Automation

SCARA-topped mobile robots zip through labs, shuttling microplates and test tubes between analyzers. The arm's precision keeps vials spill-free, while the base connects isolated automation zones.

Electronics & PCB Handling

In chip fabs, mobile SCARAs haul wafer cassettes or PCBs. That vertical rigidity ensures vibration-free slotting into processors.

Warehouse Bin Picking

Paired with 3D vision, AGV-mounted SCARAs do 'goods-to-robot' picking: roll to a shelf, snatch small items from bins into totes—ditching manual carts.

Machine Tending

One mobile SCARA can service multiple CNCs, zipping between them to load raw stock and grab finished parts. It boosts uptime without dedicating fixed bots everywhere.

Frequently Asked Questions

What does SCARA actually stand for?

SCARA stands for (or sometimes Selective Compliance Articulated Robot Arm). 'Selective Compliance' means it's a bit flexible horizontally (X-Y) for assembly finesse but rigid vertically (Z).

Why pick a SCARA over a 6-axis arm for your AGV?

SCARAs are faster, smaller, and cheaper than 6-axis arms for flat-plane tasks. If your mobile ops are mostly pick-and-place on surfaces, SCARA delivers quicker cycles and sips less AGV battery.

What are the payload limitations for mobile SCARA robots?

Standard SCARAs manage 0.5kg to 20kg payloads. Mobile ones usually cap at 3kg–10kg to keep the AGV stable and batteries happy—heavy fast arms could tip a light base.

How does the robot handle power on a mobile platform?

Mobile SCARAs run on DC (24V or 48V) to tap the AGV's battery. Smart power control is key; the arm's brain chats with the AGV's BMS to park safely before juice runs low.

Are SCARA robots safe to work alongside humans?

Old-school SCARAs are speedy but risky, needing cages. New 'Cobot' versions have force sensors and soft edges. In open mobile aisles, the AGV's safety lasers call the shots on when the arm moves.

Can a SCARA grab stuff on different shelf heights?

It's a limit: Z-reach is short (150mm–400mm). For multi-level shelves, mount the whole arm on a vertical lift atop the AGV to hit from floor to eye level.

How precise is the positioning when the AGV stops?

The SCARA's dead-on precise (±0.02mm), but AGV parking might be ±10mm off. Mobile manipulators fix it with 'visual servoing'—cameras spot workstation markers, letting the arm adjust on the fly.

What is the typical reach of a mobile SCARA?

Horizontal reach? Typically 300mm–1000mm. For doorways around 800mm wide, 400mm–600mm is sweet to keep the arm within the AGV's footprint on the move.

Is programming a SCARA difficult?

SCARA robots are usually way easier to program than 6-axis arms since their movements stick to a simple X-Y grid. Most modern controllers play nice with ROS (Robot Operating System), so integrating them with your AGV's navigation stack is a smooth ride for developers.

What maintenance is required for mobile SCARAs?

They need less maintenance than articulated arms. The main jobs are greasing the ball screw spline (that's the Z-axis shaft) and checking belt tensions. On mobile setups, don't forget to inspect cable management regularly—vibrations from travel can wear them down fast.

How does cost compare to other manipulator types?

SCARA robots are typically the best bang for your buck for assembly and pick-and-place jobs. They're much cheaper than Delta robots or 6-axis arms with similar payloads, making them perfect for building out big fleets of mobile manipulators.