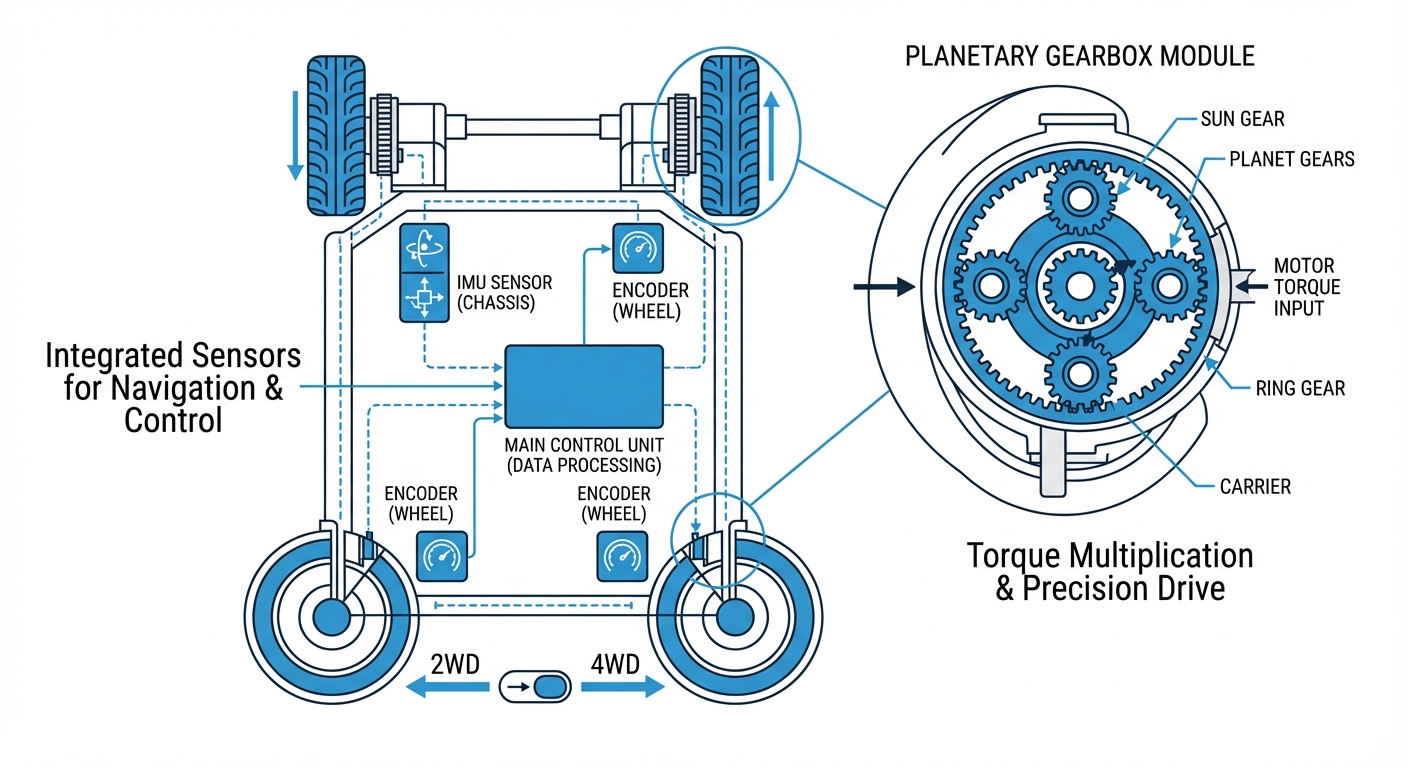

Planetary Gearboxes

Planetary gearboxes are the torque boosters for today's AGVs, blending compactness, efficiency, and heavy-load muscle. Spreading stress over multiple gears lets robots haul more with pinpoint control and longer battery runs.

Core Concepts

The Sun Gear

The central gear hooked to the motor shaft. It drives high-speed spin into the orbiting planet gears.

Planet Carrier

These orbit the sun gear inside the ring gear, sharing the load for way higher torque than basic spur gears.

The Ring Gear

The outer ring with internal teeth. Usually fixed to the housing in AGVs, making planets circle and power the output.

Gear Ratio

Sets the speed-vs-torque balance. Higher ratios like 50:1 crank up torque for big lifts but dial back max speed.

Precision & Backlash

The wiggle room in gear mesh. Ultra-low backlash is key for AGVs that need exact docking and path precision.

Transmission Efficiency

Planetary gears deliver over 95% efficiency per stage, slashing energy loss and letting your AGVs run way longer between charges.

How It Works

The planetary gearbox earns its name from its cool solar-system setup. A central 'sun' gear hooks right up to the electric motor. As it spins, it powers the 'planet' gears—mounted on a carrier—that mesh with the fixed outer 'ring' gear.

With the ring gear locked in place, the planets' rotation pushes the carrier (and output shaft) to turn. This setup dramatically slows speed while boosting torque. Plus, since the load spreads across several planet gears (usually 3 or 4), it handles way more torque than same-size parallel-axis gears.

For robotics, it's a game-changer. It lets a compact, high-speed motor power heavy AGV wheels with serious force. Stack multiple 'stages' and you get huge reduction ratios in a sleek cylinder that slips perfectly into wheel hubs or robot joints.

Real-World Applications

Warehouse Logistics (AMRs)

Perfect for differential drive in shelf-lifting robots. Their high torque density means small robots can hoist pallets over 1,000kg while staying low enough to slide under racks.

Automated Forklifts

Key for both traction drive (getting around) and hydraulic pump drive (lifting forks). They shrug off the shock loads from constant start-stops in forklifts.

Medical Transport Robots

In hospitals, quiet and smooth operation is everything. Precision planetary gears with helical teeth run nearly silent, ideal for autonomously delivering meds and linens.

Outdoor Agricultural Rovers

Outdoor AGVs battling mud and hills? Multi-stage planetary gearboxes crank out the massive torque to conquer tough terrain without frying the motors.

Frequently Asked Questions

Why pick planetary gearboxes over spur gears for AGVs?

Planetary gearboxes pack a higher torque-to-weight punch because the load spreads across multiple planet gears, not just one contact point. They're smaller, tougher for AGV payloads, while spur gears would balloon in size for the same torque.

How does gear backlash affect robot navigation?

Backlash is that tiny gap between gear teeth. Too much means 'slop' or lost motion on direction changes. For AGVs using odometry for navigation, it builds up errors, messing with precise docking. Precision planetary gears keep it under 5 arc-minutes.

What is the typical efficiency of a planetary gearbox?

Single-stage planetary gearboxes hit 95-97% efficiency. Two-stage ones do 90-94%. This matters big time for battery AGVs—less heat waste means farther per charge.

How do I pick the right gear ratio for my mobile robot?

Balance top speed needs with torque demands. Start by calculating torque to accelerate your robot's mass up the steepest slope. Then, divide motor RPM by the ratio to hit your speed goal. Warehouse AGVs often land between 20:1 and 50:1.

What maintenance do planetary gearboxes require?

Most robotic planetary gearboxes are 'lubricated for life' with synthetic grease, fully sealed—no maintenance needed for 20,000+ hours. But in brutal industrial use, check seals and heat buildup now and then.

Can planetary gearboxes handle shock loads?

Yeah, they're tough on shock loads thanks to multiple teeth sharing the force. Still, hard stops or crashes can chip teeth or snap shafts. Best to oversize with a 1.5x or 2.0x service factor for shock-prone setups.

What causes noise in planetary gearboxes and how to cut it?

Noise comes from teeth meshing vibrations. Switch to helical gears (angled teeth) over spur (straight)—they engage smoother and quieter, though a bit pricier.

What is the difference between single-stage and multi-stage gearboxes?

A single-stage has one sun/planet/ring set, up to 10:1 ratios. For 100:1, stack a second or third stage (stage 1 output drives stage 2 sun). Each adds length and a touch less efficiency.

Are plastic planetary gears suitable for robotics?

Only for super light or educational bots. Industrial AGVs with payloads need hardened steel gears for torque and wear. Plastic deforms under load, causing skips and breakdowns on mobile platforms.

How does thermal management work with these gearboxes?

Friction builds heat. Planetary gears run efficient, but nonstop high speeds can overheat and degrade lube. High-duty AGVs often bolt the gearbox to a metal chassis that doubles as a heatsink.

What’s radial vs. axial load here?

Axial is thrust along the shaft; radial is perpendicular, like AGV weight on the wheel axle. With wheels often direct-mounted to the output shaft, gearbox bearings need high radial ratings to hold the vehicle up.