Optical Rotary Encoders

Optical rotary encoders are like the nervous system of pinpoint navigation. They convert mechanical motion into the digital lingo of robotics, delivering the essential feedback loop so AGVs can nail sub-millimeter moves, stay safe, and handle efficient path planning in messy environments.

Core Concepts

Incremental Encoding

It generates pulses as the shaft turns, tracking relative motion and speed. But it needs a 'homing' routine at startup to figure out its absolute position in the warehouse.

Absolute Encoding

It gives every shaft angle its own unique digital code. Super important for robotic arms and safety setups, since it holds onto position data even after a full power outage.

Resolution (PPR)

Pulses Per Revolution sets the measurement detail. Go higher (like 5000 PPR) for silky-smooth speed control, even at super low speeds.

Quadrature Output

It uses two signal channels, A and B, offset by 90 degrees. By seeing which one fires first, the AGV's controller instantly knows the rotation direction.

The Optical Disc

At the heart: a glass or metal disc etched with tiny transparent and opaque lines that chop a light beam to create those signal pulses.

Index Channel (Z)

A 'Z' channel fires one pulse per revolution. It acts as a rock-solid zero-reference to double-check position counts over long runs.

How It Works

The magic inside an optical rotary encoder is pure optoelectronics brilliance. An LED shoots a tight light beam through a spinning code disc patterned with precise lines—like wheel spokes—that switch between clear and blocked.

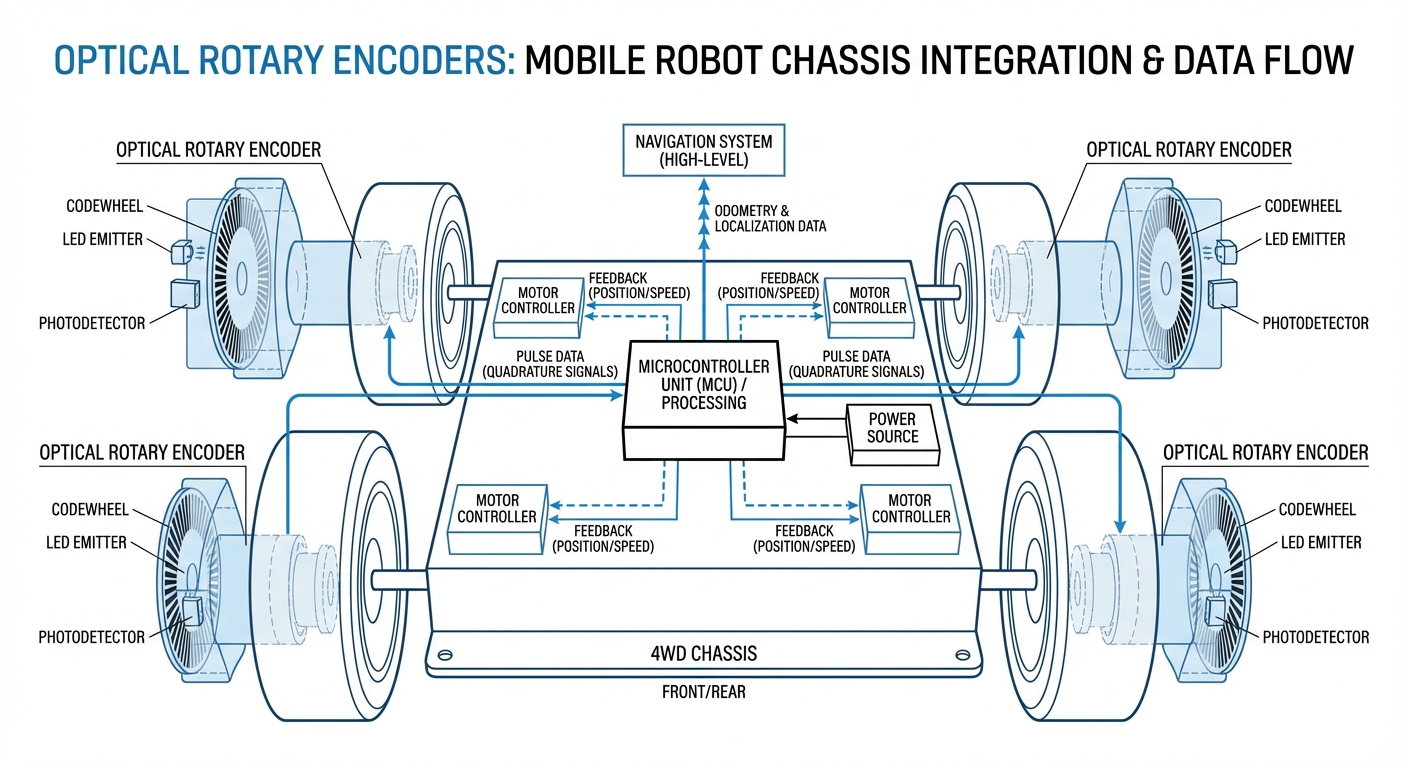

As the disc spins with the AGV's motor shaft, it chops up the light beam. A photodetector on the other side catches these light flashes and turns them into electrical pulses (square waves).

Those pulses head straight to the AGV's main processor or PLC. Count the pulse frequency for speed, total pulses for distance traveled. The phase difference tells forward from reverse, powering precise PID control for buttery-smooth navigation.

Real-World Applications

Dead Reckoning Navigation

In spots where GPS or LiDAR can't see, AGVs lean fully on wheel odometry from encoders to guess their position from a known starting point.

Forklift Mast Positioning

Automated forklifts use absolute encoders on the lift motor to track fork height exactly, nailing millimeter-precise pallet picks and places way up high on racks.

Differential Steering

To turn, mobile robots spin wheels at different speeds. Encoders give the feedback to sync those speeds perfectly, hitting exact turning radii without tire slip.

Conveyor Synchronization

When an AGV docks to a fixed conveyor, encoders match the robot's roller speed to the conveyor's, making goods transfer seamless and jerk-free.

Frequently Asked Questions

Optical vs. Magnetic Encoders: Which is better for AGVs?

Optical encoders shine with top resolution and accuracy—perfect for precise nav and positioning. Magnetic ones tough out dust, oil, and vibes better. Clean warehouses? Optical rules. Rough factory floors? Go magnetic.

What resolution (PPR) do I need for my robot?

It boils down to your wheel size and position accuracy needs. For typical warehouse AGVs, 1024 to 4096 PPR is standard. Higher PPR means smoother low-speed control—key for docking—but demands faster processing.

How does dust affect optical encoders?

Dust on the optical disc can block light and skip pulses since it relies on transmission. For robots, pick encoders with high IP ratings (IP65 or IP67) and sealed housings to keep gunk out.

Why use an Absolute encoder instead of an Incremental one?

Absolute encoders know their exact position right at power-up—no movement needed. Way safer for lifts or steering where a 'homing run' to find zero could be risky or impossible post-power failure.

What is the interface typically used for AGV encoders?

Incremental ones usually run Push-Pull (HTL) or RS422 (TTL) logic. Absolutes often use protocols like SSI, BiSS, CANopen, or EtherCAT, slipping easily into modern factory fieldbus networks.

How do I troubleshoot signal noise in encoder cables?

Encoder signals hate electrical noise from motor drives. Use twisted-pair shielded cables, ground the shield only at the drive end, and keep encoder cables far from power lines. Differential signaling (RS422) slashes noise big time.

What causes encoder failure in mobile robots?

Top culprits: mechanical bearing wear from shaft overload (misalignment), vibes wrecking the glass disc, or fluids sneaking in to fry electronics. Flexible couplings for mounting are key to long life.

Does temperature affect optical encoder performance?

Yep. Extreme heat wears down the LED over time; bitter cold brings condensation on the disc. Match the encoder rating to your environment—crucial for AGVs hitting cold storage.

What is the "Index Pulse" and do I need it?

The Index (or Z channel) pulses once per full turn. Great for error-checking—if the count's off when Z hits, you know something slipped. Highly recommended for reliable nav.

Can I retrofit optical encoders onto existing motors?

Yep, tons of 'kit encoders' or hollow-shaft types mount right on the back of existing DC or BLDC motors. Just match the shaft diameter and have a spot for the tether or stator.

What is the difference between single-turn and multi-turn absolute encoders?

Single-turn tracks position within one 360-degree spin (0 to 359). Multi-turn does that PLUS counts total revolutions. Vital for linear actuators or wheels covering long hauls.

How does an optical encoder calculate speed?

The controller figures speed by pulse frequency (pulses per second) or time between pulses—the latter's sharper for slow AGVs.