Millimeter Wave Radar

Supercharge your AMRs with all-weather sensing. Millimeter wave radar nails range, velocity, and angle—even in dust, fog, or dim factories where cameras flop.

Core Concepts

FMCW Technology

FMCW tech lets radar measure distance precisely by sending a frequency-sweeping continuous signal.

Doppler Velocity

Unlike LiDAR, radar grabs radial velocity instantly via Doppler—key for dodging moving obstacles.

Environmental Robustness

Millimeter waves (60GHz or 77GHz) cut through dust, smoke, fog, rain—rock-solid in gritty plants where cameras fail.

4D Point Cloud

Modern imaging radars spit out 4D point clouds (range, azimuth, elevation, velocity), so AGVs spot static racks vs. moving forklifts.

Range Resolution

High-bandwidth radars resolve close objects, avoiding fake walls in tight gaps.

MIMO Antenna Arrays

MIMO tech creates virtual antenna arrays for sharp angular resolution without bulking up the sensor.

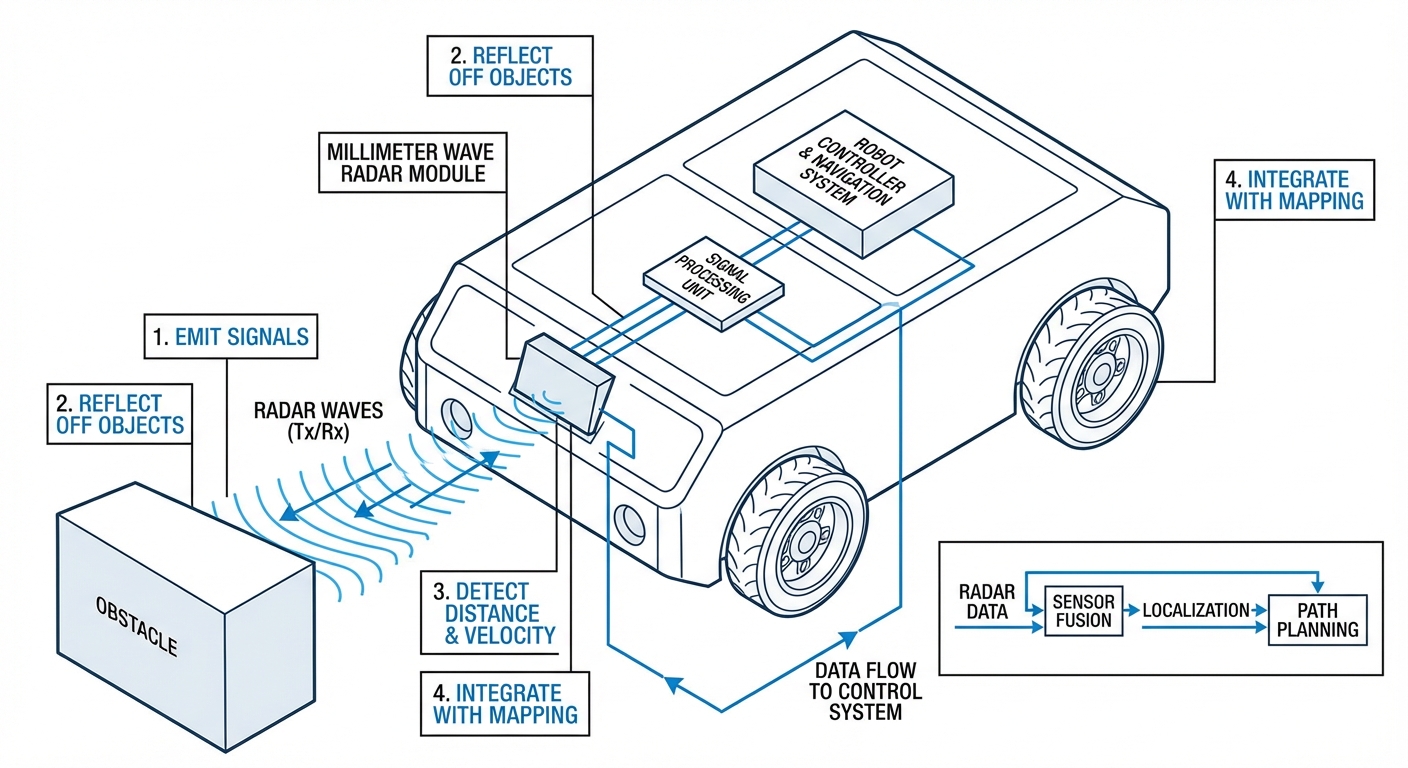

How It Works

Millimeter wave radar works by beaming waves in the 30-300GHz spectrum (77GHz is robotics sweet spot for range/resolution).

Waves bounce off pallets, people, walls back to the receiver. ToF and frequency shift reveal distance and speed. Radio waves ignore light-based glitches that fool cameras.

Advanced processing like FFT turns raw signals into digital point clouds. This feeds the AGV nav stack, fused with LiDAR/camera via Kalman filter for a full surroundings map.

For AGVs, it means seeing through steam in food plants or spotting glass doors LiDAR misses—extra safety layers.

Real-World Applications

Cold Storage & Warehousing

Cold storage with fog? Lenses fog; radar doesn't. AGVs cruise freezers and docks safely.

Outdoor Heavy Logistics

Autonomous tuggers between buildings? Radar ignores rain/snow clutter but catches crossing vehicles.

Glass Handling Facilities

LiDAR/cameras miss glass walls. Radar bounces off glass, dodging crashes in glass plants.

Smart Hospital Delivery

Hospitals buzz with people and wonky lights. Radar tracks gurney/staff speeds for smart pathing and dodging.

Frequently Asked Questions

How does mmWave radar stack up vs. LiDAR for AGVs?

LiDAR wins on angular res and 3D mapping for SLAM. Radar rules harsh conditions (dust/fog/bright) with direct Doppler velocity. Fuse 'em for top safety.

Can radar spot transparent objects like glass or clear plastic?

Yep, that's one of radar's biggest strengths. Cameras just see right through glass, and LiDAR often gets thrown off by weird refractions. But millimeter waves bounce off solid surfaces no matter how see-through they are. That's why radar shines in spots with glass doors or shrink-wrapped pallets.

What's the usual range and field of view (FOV)?

For industrial AGVs, short-range radar (SRR) handles 0.2m to 30m with a super-wide FOV—up to 120° azimuth—perfect for bumper protection. Medium- and long-range ones stretch to 100m+ but with a narrower FOV, great for zooming down high-speed corridors.

Is radar susceptible to interference from other robots?

Interference can happen if multiple robots blast signals at the exact same frequency and timing. But modern FMCW radars dodge this with randomized chirp slopes and smart interference-busting algorithms, so you can pack a dense fleet of robots into one warehouse without any crosstalk drama.

What 'blind spots' should I watch out for?

Radar has a minimum detection range—usually 4cm to 20cm, depending on bandwidth. Anything closer might slip by. That's why it's smart to team it up with ultrasonic sensors or bumpers for up-close collision detection.

Does the radar integrate with ROS/ROS2?

Yep, most off-the-shelf industrial radars (think TI, Bosch, or Continental) come with ROS and ROS2 drivers ready to go. They spit out a `PointCloud2` message packed with x, y, z coords, plus intensity and velocity data, making it a breeze to plug into your navigation stack.

What is the power consumption compared to other sensors?

Millimeter wave radar sips power—a typical module uses just 2W to 5W. Way less than beefy 3D spinning LiDARs (10W-20W) or compute-heavy vision setups. It really stretches your AGV fleet's battery life.

Can radar handle safety certification like PL-d or SIL 2?

Totally—there are safety-rated radars built just for industrial use. They pack self-diagnostics and redundant designs to hit Performance Level d (PL-d) or Safety Integrity Level 2 (SIL 2), so you can rely on them for speed tweaks and emergency stops.

How does material type affect detection?

Metal and water (yep, including human bodies) reflect millimeter waves like champs and show up crystal clear. Wood, concrete, and plastic work great too. Low-density foam or radar-absorbing stuff can be trickier, but that's rare in everyday warehouses.

Is calibration difficult?

Calibration's easier than with stereo cameras, but you still need it. Just set the mounting position (x, y, z, yaw, pitch, roll) relative to the robot's center. Lots of new radars even auto-calibrate by tweaking params as the bot rolls through a familiar static space.

What happens in environments with high vibration?

Radars are solid-state—no moving parts—so they're tough as nails against vibes and shocks, unlike spinning LiDARs. Extreme shaking might add noise to velocity readings, but soft-mounting or software filters usually sort it out.

Why choose 77GHz over 24GHz?

The 77GHz band gives you way more bandwidth (up to 4GHz) than the skinny 24GHz ISM band. That means killer range resolution for spotting close objects and tinier antennas, so sensors fit snugly into AGV frames.