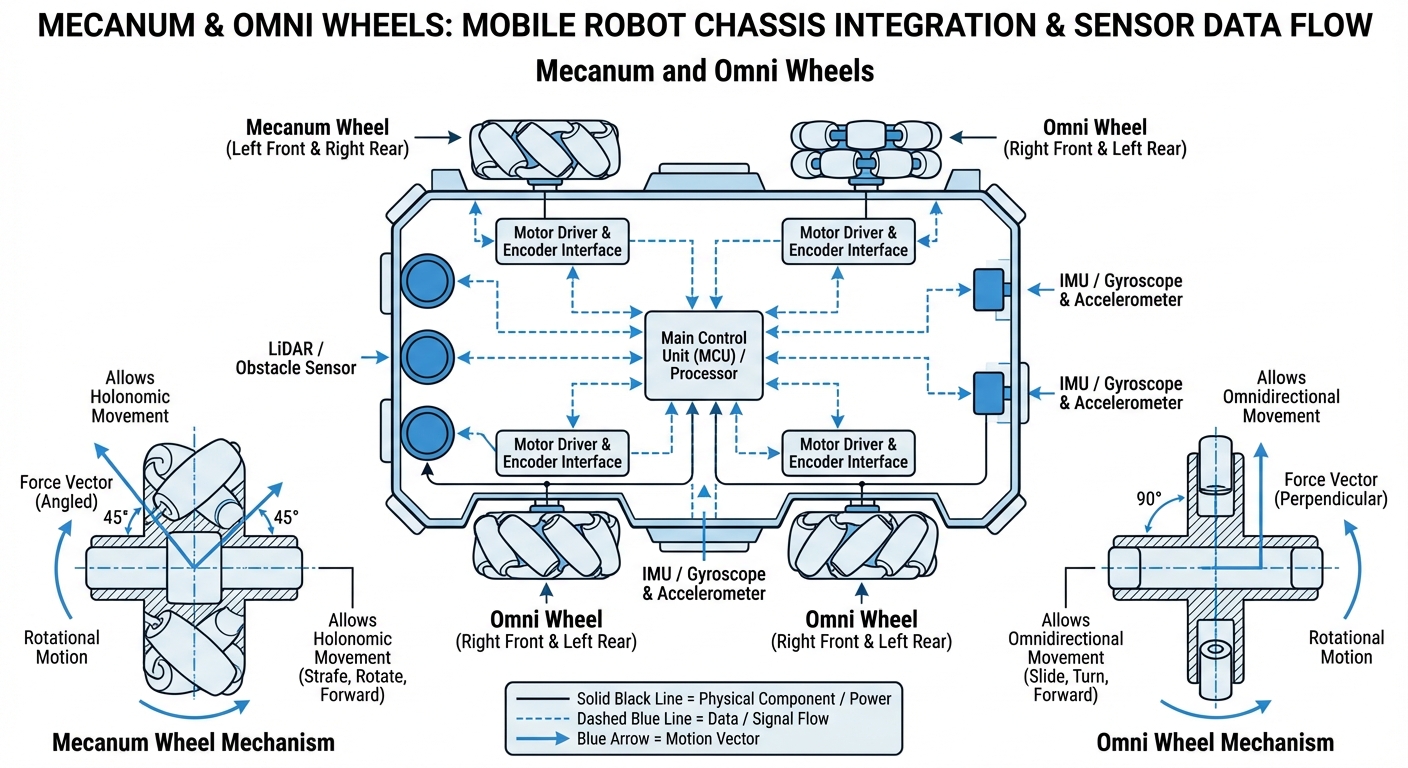

Mecanum and Omni Wheels

Unlock real holonomic agility for your AGVs. Mecanum and omni wheels transform mobile robotics, letting you zip in any direction instantly—no turning required—perfect for tight, tricky spaces.

Core Concepts

Holonomic Motion

The power to move along X and Y axes at the same time, plus rotate (Theta). That gives your robot full 3 degrees of freedom on the ground.

Vector Addition

It’s all about adding up forces from independent wheels. Opposing forces cancel out for pure sideways strafing.

Roller Architecture

Unlike regular tires, these have passive rollers around the edge. Mecanum rollers sit at 45°, Omni at 90°.

Independent Control

Holonomic moves need each wheel with its own motor and encoder. No shared differential gearboxes here.

Traction Dynamics

Success hinges on solid ground contact for every wheel. Bumpy floors make rollers slip, throwing off the robot’s kinematic math.

Payload Stability

Since motion pulls in non-forward vectors, a stiff chassis and even weight distribution are key to avoid wheels lifting off.

How It Works: Vector Kinematics

The magic of holonomic wheels lies in the passive rollers attached to the wheel's circumference. In a wheel, these rollers are positioned at a 45-degree angle to the axis of rotation. When the wheel spins, it generates force vector that has both a forward component and a sideways component.

By blending rotations from four independent wheels, an AGV controls those vectors. Spin front-left and rear-right forward, the others backward, and forward motion cancels—pure sideways strafe.

Omni wheels

Real-World Applications

High-Density Warehousing

In super-narrow aisles just inches wider than the AGV, turning’s a no-go. Mecanum AGVs slide right in, strafe to grab the pallet, lift, and strafe out—maxing storage space.

Precision Manufacturing

Assembly robots need sub-millimeter part alignment. Holonomic wheels let you tweak position and rotation together without shifting the base.

Medical Transport

Crowded hospital halls full of gear and people? Omni-wheel robots dodge obstacles on a dime, no wide turns like differential drives.

Stage & Studio Logistics

Silently shifting heavy set pieces any way you want makes scene changes seamless. Rotate-in-place rocks for tight backstage spots.

Frequently Asked Questions

What’s the biggest difference between Mecanum and Omni wheels?

It boils down to roller angle. Omni wheels have 90° rollers to the axis for killer forward grip but no side resistance. Mecanum’s 45° rollers fit standard parallel chassis (car-style) and create sideways via vector math.

Can Mecanum wheels handle uneven ground or outdoors?

Usually not. They need all four wheels planted evenly for accurate vectors. Bumps, cracks, or junk make rollers slip or lift, turning navigation wonky. Stick to flat, smooth indoor floors.

How does load capacity stack up against standard rubber tires?

Mecanum and Omni wheels usually handle less load than solid rubber tires of the same size. The weight focuses on those tiny roller contact patches instead of the full wheel, creating high-pressure spots that can deform the rollers under heavy loads.

Do I need a suspension system for Mecanum robots?

Yeah, suspension is a must. If a wheel lifts off the ground, the kinematics break down completely. Suspension keeps all four wheels gripping, even on slightly bumpy floors. A basic pivoted axle or spring caster does the trick.

Are these wheels less energy efficient than standard wheels?

Yep, they're less efficient overall. To slide sideways, the motors cancel vectors against each other, wasting power. Plus, roller friction drags down rolling efficiency compared to smooth bearing wheels.

What type of motor control is required?

You need independent control for each wheel (typically 4 motors for Mecanum). Skip the single motor with differential. Your controller must do closed-loop PID to hit exact RPMs per wheel, or the robot drifts everywhere.

How do I calculate wheel speeds for a specific direction?

You'll use a kinematic matrix. For a standard 4-wheel Mecanum setup, each wheel speed adds up the forward (Y), strafe (X), and rotation (Theta) velocities, flipping signs based on the wheel's position.

Why does my Mecanum robot vibrate or wobble?

Vibration usually comes from gaps between rollers—the contact point jumps as the wheel spins from one to the next. High-quality wheels shrink those gaps, but some shake is built-in. Bent axles or gunk in the rollers make it worse too.

Are Omni wheels better for specific layouts?

Omni wheels are perfect for 3-wheel "Kiwi" drives (triangular layout) or H-drives (5 wheels). They're often cheaper than Mecanum since the wheels are simpler to build, though the funky chassis shape can be tricky in square spaces like warehouses.

How much maintenance do these wheels require?

Way more than standard wheels. Those little roller axles snag hair, dust, and carpet fibers, spiking friction and throwing off your vectors. Clean and lube the axles regularly to keep things smooth.

Can I retrofit an existing robot with Mecanum wheels?

Only if you've already got 4 independent motors. Skid-steering (tank drive) with chained left/right wheels won't cut it—you can't just swap wheels. Upgrade motor drivers and tweak the control code.

Do Mecanum wheels wear out faster?

Yes, they wear faster. Smaller rollers scrub hard during strafes and turns, and with less contact area, the rubber chews up quicker per mile than a regular tire.