LiFePO4 Batteries

Lithium Iron Phosphate is the top pick for today's mobile robots, delivering round-the-clock uptime via quick opportunity charges, unbeatable heat stability, and way lower ownership costs than old-school batteries.

Core Concepts

Safety Profile

LiFePO4 stays cool and doesn't burn. Unlike NMC or NCA lithium packs, it's practically immune to thermal runaway—the safest bet for robots around people.

Cycle Life

It cranks out 2,000 to 5,000+ full cycles before hitting 80% capacity. That's 4-5x more than lead-acid, matching the robot's full lifespan.

Opportunity Charging

It handles fast charges during short stops without hurting the cells, powering '24/7 free run' AGVs—no need for swaps.

Flat Discharge Curve

It holds steady at about 3.2V per cell right up to the end, keeping motors punchy and sensors sharp all shift long.

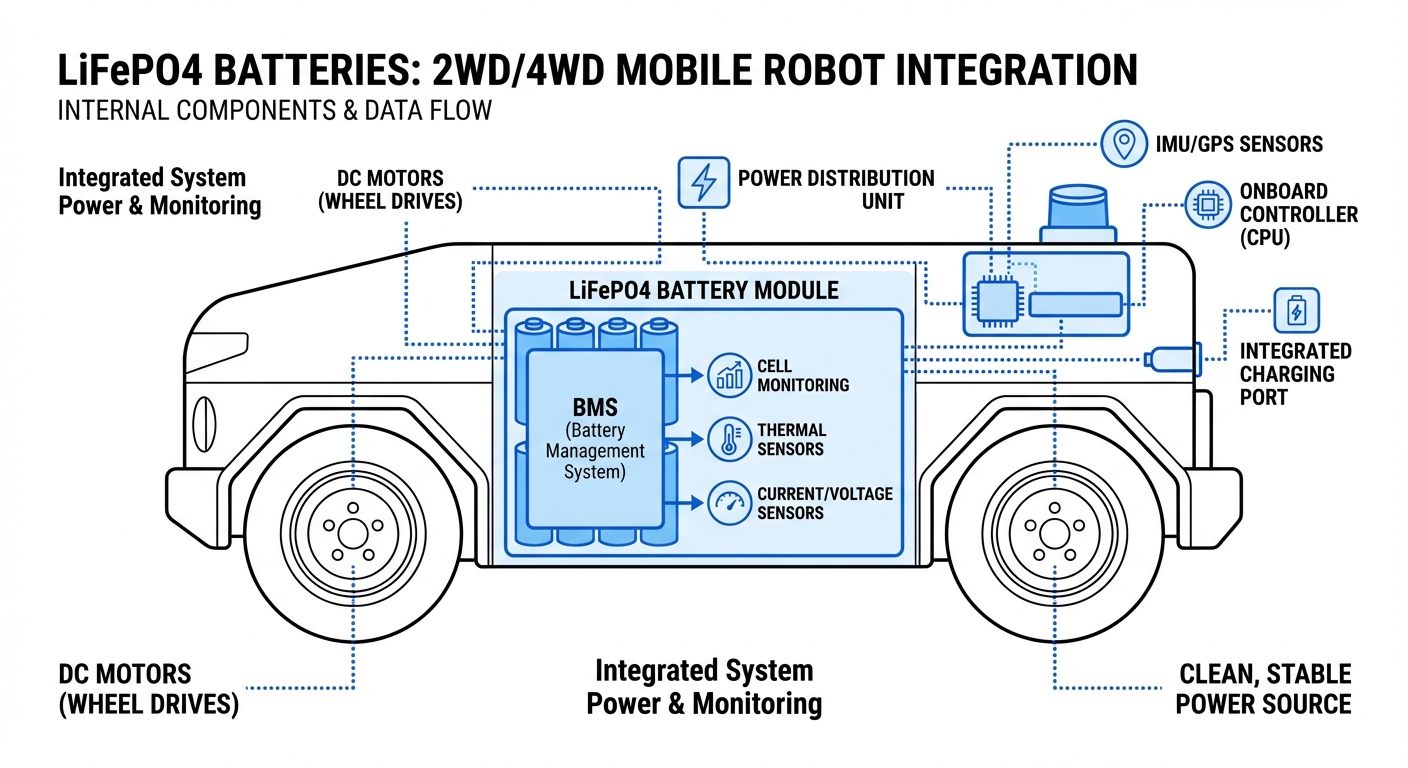

BMS Integration

Every pack needs a Battery Management System (BMS) to balance cells, guard against over/under-voltage and shorts, and talk straight to the robot controller over CAN bus.

Depth of Discharge

It takes 100% Depth of Discharge without much wear, unlike lead-acid that gets ruined below 50%.

How It Works

At its core, the LiFePO4 cathode is Lithium Iron Phosphate. This structure has lower resistance than other lithium types, meaning top-notch heat tolerance and power delivery.

When discharging to run the robot, lithium ions flow from the graphite anode to the LiFePO4 cathode via electrolyte. Those tough phosphate bonds lock in oxygen, so no fire risk even if punctured or crushed.

For robotics, the crucial aspect is the . While a lead-acid battery's voltage drops steadily as it empties (slowing robots down), LiFePO4 pumps full power until the last few percent, keeping your AGVs at peak efficiency until they plug in.

Real-World Applications

E-Commerce Fulfillment (AMRs)

High-speed sorters love LiFePO4 for its light weight and quick charges. They top up for 5 minutes hourly, running 24/7 without swaps.

Heavy Manufacturing (AGVs)

Tuggers hauling car chassis get steady voltage for constant torque, even with heavy loads late in the shift.

Healthcare & Cleanrooms

LiFePO4 charges without gassing (unlike lead-acid), making it required for clean spots like hospitals or chip fabs.

Cold Chain Logistics

Better cold performance than lead-acid, and with built-in heaters, LiFePO4 keeps freezer forklifts humming.

Frequently Asked Questions

What distinguishes LiFePO4 from standard Lithium-Ion (NMC/NCA) batteries?

The big difference is the cathode: LiFePO4 (LFP) uses iron phosphate—heavier and less energy-packed than NMC's nickel-manganese-cobalt mix—but it's safer (no runaway), lasts longer, and costs less without pricey cobalt.

Why are LiFePO4 batteries preferred for AGVs over Lead-Acid?

LFP gives 4-5x more cycles, full 100% discharge safely, zero upkeep (no watering), 5x faster charging, and half the weight of lead-acid—boosting your robot's payload.

Is a Battery Management System (BMS) mandatory?

Yes, for sure. The BMS watches cell voltages, temps, and currents, balances them for long life, and cuts power on issues like shorts or over-discharge to save your robot gear.

Can I retrofit an existing lead-acid AGV with LiFePO4?

Usually yes—it's a straightforward swap. But switch to a lithium-specific charger and check counterweights, since LFP is much lighter than lead-acid.

What’s “Opportunity Charging” all about, and does it harm the battery?

Opportunity charging just means giving your robot a quick top-up during breaks or downtime. Unlike lead-acid batteries that need a full charge cycle to avoid memory effect, LiFePO4 batteries actually love partial charges—it’s totally safe and super efficient for nonstop 24/7 operations.

What’s the typical voltage range for a 24V or 48V LiFePO4 pack?

A so-called “24V” LiFePO4 battery is usually an 8-series (8S) setup, sitting at 25.6V normally and charging up to 29.2V. A “48V” one is typically 15S or 16S, hitting 54.7V or 58.4V when fully charged. Your robot’s electronics have to handle those peak voltages.

Do these batteries have a "Memory Effect"?

No, LiFePO4 batteries have zero memory effect. You don’t need to fully drain them before recharging. Actually, keeping them partially charged (say, 20% to 80%) often helps them last even longer.

How does temperature affect performance?

Discharging works great from -20°C to 60°C. But standard LiFePO4 batteries can’t be below freezing (0°C) or they’ll suffer permanent plating damage. For cold storage jobs, you’ll want self-heating battery packs.

What is the expected ROI timeline?

Sure, they cost 2-3x more upfront than lead-acid, but you’ll typically see your investment back in 12-18 months—no more maintenance hassles, batteries that last 5+ years without replacement, and big energy savings from better charging efficiency.

Are LiFePO4 batteries environmentally friendly?

They’re the “greenest” lithium choice out there. No nasty heavy metals like cobalt or lead, totally non-toxic to soil, and made from abundant, increasingly recyclable stuff like lithium, iron, and phosphate—way better than other types.