Impedance Control

Want to make your Autonomous Guided Vehicles safer and more responsive? Master how force and motion interplay with impedance control. It lets robots smartly interact with their surroundings, soaking up bumps and disruptions for safe teamwork with human workers.

Core Concepts

Mass-Spring-Damper

At its core, it's a math model that turns the robot into a virtual spring. It gently resists veering off course using stiffness and damping settings, ditching rigid positioning for something smarter.

Active Compliance

It lets the AGV give way during surprise bumps. Rather than powering through obstacles with full torque, it senses pushback and adapts on the fly.

Force Feedback

It taps into torque sensors or motor current to keep the feedback loop tight. This real-time info helps the controller instantly tell free movement from actual contact.

Dynamic Safety

It boosts human-robot teamwork by capping collision forces, creating a 'soft' buffer that's key for meeting ISO safety standards.

Variable Stiffness

These are algorithms that tweak stiffness on the fly. The robot stays firm for pinpoint tasks but goes soft and flexible in messy or crowded spots.

Disturbance Rejection

It sifts out minor annoyances like bumpy floors or light friction, keeping the path steady without overreacting and jerking the wheels.

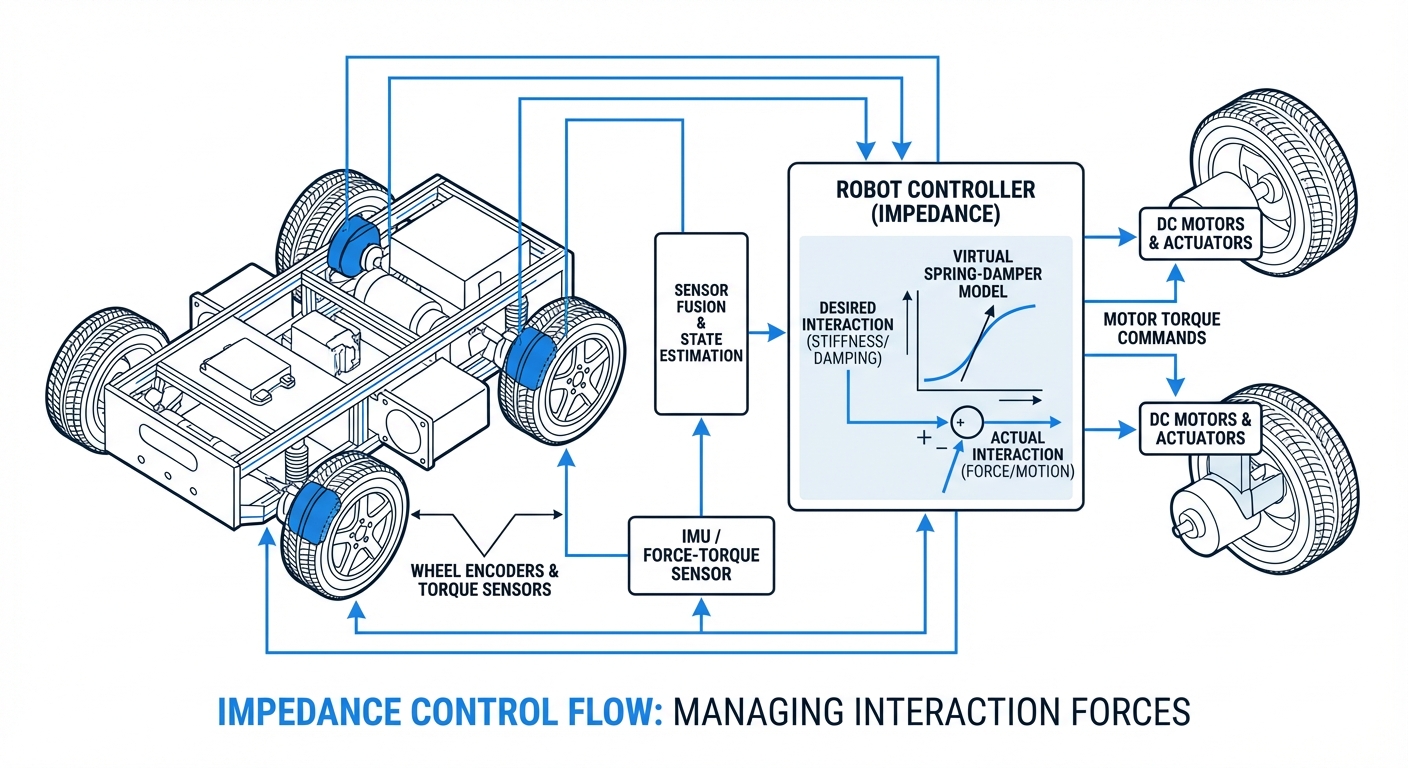

How It Works

Old-school position control bulldozes the robot to exact spots, no matter what's in the way—leading to nasty high-force crashes. Impedance control turns that around by balancing force and position dynamically.

Picture the robot tethered to its ideal path by an invisible spring. Get pushed off (by a bump or person)? The spring stretches, and the controller figures out just the right pull-back force based on its stiffness.

The result? A robot that cushions impacts softly but still nails transport jobs accurately. For AGVs, that's the line between a workflow-killing hard stop and a smooth nudge that keeps things rolling.

Real-World Applications

Collaborative Assembly

In car assembly lines, AGVs haul chassis while workers bolt on parts. Impedance control means if someone nudges the AGV, it flexes a bit instead of locking up or risking injury—perfect for smooth collaboration.

Crowded Warehouses

In busy warehouses, dodging close calls is routine. Impedance control gives AMRs squishy 'bumpers' for tight squeezes, cutting down on scrapes and avoiding gridlock.

Docking & Charging

Docking precisely means touching the charger just right. Impedance control helps the robot 'feel' the connection and glide in without smashing the contacts.

Uneven Terrain Handling

Outdoors or on rough floors, stiff control leads to shakes and slips. Impedance control works like virtual shocks, tweaking wheel power to grip bumps and ramps steadily.

Frequently Asked Questions

What is the difference between Impedance and Admittance Control?

Both handle force and motion, but the direction flips. Impedance takes motion cues and spits out force (spring-like), great for light, backdrivable bots. Admittance takes force and outputs motion, suited for hefty industrial rigs.

Does Impedance Control require expensive force-torque sensors?

Not necessarily. Top-end 6-axis sensors give the best read, but plenty of AGVs use motor current tricks (proprioception) to guess external forces from torque—cheaper and still safe for navigation.

How does this impact battery life on mobile robots?

Impedance might chew a bit more CPU than basic PID, but it saves big on energy. No more motors straining against walls or friction at full blast, so less current draw that often offsets the extra compute.

Can I retrofit existing AGVs with Impedance Control?

Depends on your setup. If drivers handle torque mode and you can tweak low-level loops (CAN or EtherCAT), a software tweak might do it. Locked-down proprietary gear? Probably need new hardware.

Is Impedance Control safe for high-speed AGV operations?

Yep, with smart variable tuning. Crank stiffness high for speed to track paths tight; dial it down for docking or collab zones as it slows.

How difficult is it to tune the Mass-Spring-Damper parameters?

Tuning's tricky since stability rules—bad damping means wobbles on contact. Luckily, sim tools like Gazebo or Isaac Sim let you dial it in virtually before going live.

Does this replace standard LiDAR safety fields?

Nope, it layers on top. LiDAR handles no-touch avoidance; impedance is your contact-safety net or for planned touches. It's the final safeguard if something slips into the danger zone too fast to brake.

Is Impedance Control supported in ROS 2?

Totally. ROS 2 Control has solid impedance and admittance support (`ros2_control`). Grab standard packages for diff-drive or holonomic bots with barely any custom code.

How does payload variation affect performance?

Big payload shifts mess with inertia, throwing off the controller. Pro setups use 'Adaptive Impedance Control' to guess mass on the fly and tweak virtual mass params.

What happens if the robot gets "stuck" due to low stiffness?

Too-low stiffness? The robot might lack oomph to beat friction or tiny hurdles (steady error). Fix it with an integral term in the loop or hybrid force/position for tough spots.

Does this work on uneven or ramped surfaces?

Yes—and often smoother than rigid setups. On ramps, gravity fights back hard against stiff bots, risking spins. Impedance yields a tad to gravity while pushing ahead for better grip.

What is the typical latency for the control loop?

For solid impedance with contacts, loops need speed—1kHz (1ms) or quicker. Slower ones feel mushy or shaky, with reactions lagging the hit.