I2C Communication Protocol

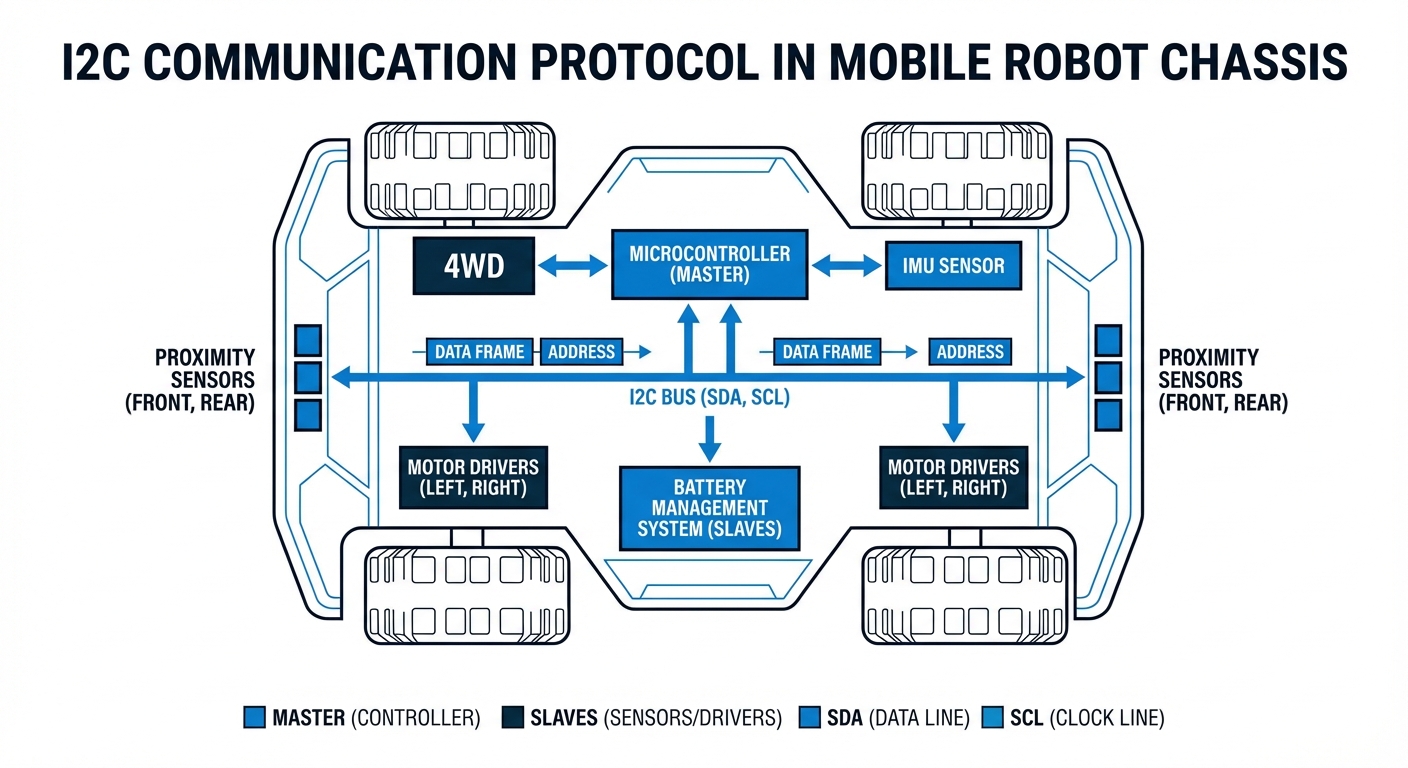

I2C is like the nervous system of today's AGVs, handling smooth, two-wire chats between microcontrollers and key sensors. It cuts down wiring headaches while keeping strong addressing, perfect for lean, high-performance robot builds.

Core Concepts

Master-Slave Architecture

In an AGV, the main computer is the Master, firing off commands. Sensors like LIDAR, thermal, and ultrasonic are Slaves, only chiming in when called.

SDA (Serial Data)

That's the bi-directional data line where all the info bits flow—addresses, commands, sensor data—between the robot's brain and its peripherals.

SCL (Serial Clock)

This is the clock signal from the Master. It keeps everything in sync, making sure bits are sampled at just the right instant across the board.

7-Bit Addressing

Every device on the I2C bus gets its own unique ID, letting one microcontroller juggle up to 127 sensors with just two wires.

Open-Drain Design

I2C pins can pull lines low to ground but can't push them high. That's to avoid shorts if two devices try talking at once.

Pull-Up Resistors

You need external resistors to pull SDA and SCL up to the logic high when idle, so the bus always starts in a clear state for reliable chats.

How It Works

I2C runs on a synchronous, packet-switched setup that's rock-solid for automated spaces. It kicks off with a 'Start Condition'—Master drops SDA low while SCL stays high—waking up all sensors to listen for their address.

Next, the Master sends a 7- or 10-bit address plus a Read/Write bit. Only the matching sensor ACKs it. Then data flows byte by byte (8 bits each), with ACK/NACK after every one to check it's all good.

For AGVs, this setup lets the main processor zip through proximity sensors, battery checks, and IMUs. No ACK? Boom—error handling or safety stop kicks in, keeping things safe in busy warehouses.

Real-World Applications

Inertial Measurement Units (IMUs)

I2C links gyros and accelerometers to the CPU for live orientation info, stopping AGVs from tipping on sharp turns or wonky loads.

Battery Management Systems

Fuel gauge chips spit out voltage, temp, and current stats over I2C, so fleet managers can nail charging predictions.

ToF Distance Sensors

Time-of-Flight sensors beam distance data via I2C to the nav controller for spot-on wall-following and obstacle spotting in tight aisles.

OLED Diagnostic Displays

Those little maintenance screens right on the robot chassis hook up via I2C, letting techs pull error codes and status without lugging a laptop.

Frequently Asked Questions

What's the max effective distance for I2C in an AGV?

I2C's built for short hops between boards—centimeters to maybe half a meter. In robots, longer chassis runs (over 1m) mess with signals due to capacitance. For distance, add bus buffers or I2C extenders—or switch to CAN bus.

Why choose I2C over SPI for connecting robot sensors?

The big win? Pin savings. Just two wires (SDA, SCL) for 127 devices, vs. SPI's four wires plus a Chip Select per device. In tight robots with scarce GPIO, I2C streamlines wiring and boards big time.

What’s I2C Clock Stretching, and why care?

Clock stretching is when a Slave (slow sensor) holds SCL low to make the Master pause. It's saying, 'Hold up, I'm processing.' In AGVs, ignore it and you get junk data or timeouts, screwing navigation.

How do I handle I2C address conflicts?

Fixed addresses on sensors mean clashes with multiples (like four same LIDARs). Fix with an I2C mux to switch channels, or grab ones with jumper-selectable addresses.

What speed should I use for AGV sensors?

Standard Mode (100 kbps) works for basics like temp or battery. But for nav must-haves like IMUs or gyros, go Fast Mode (400 kbps) or Plus (1 Mbps) to slash control loop lag.

Is I2C susceptible to noise in industrial environments?

Absolutely. I2C's high-impedance setup picks up EMI easy from factory motors or VFDs. Use shielded cables, beefy pull-ups, and route away from power lines.

Can I2C be used for safety-critical communication?

Usually not. No strong error checks like CRC (unlike CAN). For e-stops or critical safety, stick to tougher protocols with noise-proofing and diff signaling.

What value pull-up resistors should I use?

Typical pull-ups are 2.2kΩ to 10kΩ. Go lower (stronger) for fast speeds (400kHz+) or long runs to crisp edges. Too low, and devices can't sink enough for a clean low.

How do I troubleshoot a frozen I2C bus?

Slaves crashing and locking SDA low is classic. Smart Masters toggle SCL 9 times to flush and reset. Logic analyzer's your best buddy for debugging hangs.

Does I2C support hot-swapping sensors?

Standard I2C hates hot-swapping—glitches can crash the bus. For modular AGVs, use hot-swap buffers like PCA9511.