Hydrogen Fuel Cells

Transform your automated fleet with non-stop uptime and quick refuels. Hydrogen fuel cells pack more energy punch with zero emissions, ditching battery charging delays.

Core Concepts

Rapid Refueling

Batteries take hours to juice up—hydrogen tanks refill in just 2-3 minutes for almost constant robot action.

High Energy Density

Hydrogen beats Li-ion on energy-per-pound, letting AGVs haul heavier loads longer without slowing down.

Constant Voltage

Fuel cells pump steady power till empty—no fading torque or lift speed as fuel drops.

PEM Technology

Proton Exchange Membrane (PEM) cells are robotics' pick, running cool for indoor warehouses.

Zero Emissions

The only exhaust? Pure water vapor—safe for sealed factories with basic vents.

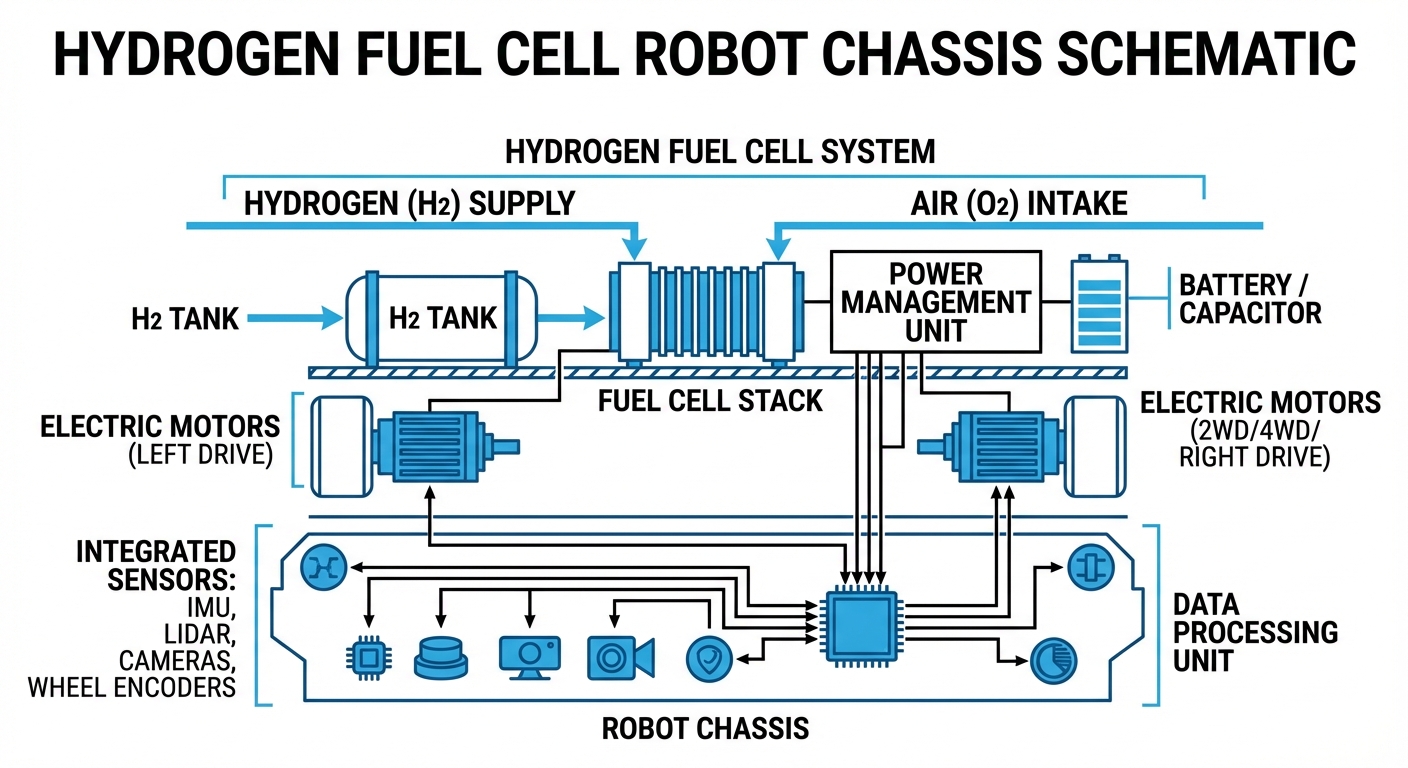

Hybrid Buffer

Most setups add a small battery or supercap for heavy lifts, while the fuel cell cruises steady.

How It Works

At the core is the Fuel Cell Power Module (FCPM). Onboard hydrogen tanks feed gas to the stack, mixing with air's oxygen.

In the stack, electrochemistry splits hydrogen's electrons and protons. Protons slip through a membrane; electrons power the circuit, driving motors and sensors.

It's whisper-quiet and vibration-free. Few moving parts mean top reliability and easy upkeep for your fleet.

Real-World Applications

Cold Storage & Logistics

Batteries tank in the cold—hydrogen fuel cells stay at full power down to -30°C, perfect for frozen food logistics.

24/7 Manufacturing

In auto or heavy plants, downtime kills. H2 bots run three shifts with quick pit stops—no swap stations or long charges.

Large-Scale Fulfillment

For huge spots over 500,000 sq ft, hydrogen's tiny setup (one dispenser vs. charger hordes) frees floor for stock.

Heavy Payload Transport

Hauling 2+ tons? Giant batteries bog you down—hydrogen delivers power density for tuggers and lifters without the heft.

Frequently Asked Questions

Is hydrogen safe for indoor warehouse use?

Yep, today's hydrogen is safety-first. Leak sensors auto-shut valves, and since it's lighter than air, it rises and vanishes fast—not pooling like propane.

Can I retrofit my existing battery-powered AGVs?

Often, yes. Many makers sell 'drop-in' H2 units that slot into old lead-acid spots, matching voltage so no big software tweaks.

How does total cost of ownership stack up against Li-ion?

Upfront H2 costs more for bots and setup, but for big fleets (20+), TCO drops thanks to saved space (bye charging rooms), more uptime, and batteries' shorter life.

What infrastructure is required to implement this?

You need a dispenser and H2 supply (liquid or compressed). It's like a gas pump. Small fleets? 'Hydrogen-as-a-service' delivers fuel—no huge on-site builds.

How long does a fuel cell stack last?

PEM stacks for handling last 10,000-20,000+ hours. Unlike batteries fading slow, refurb the stack and reuse the rest.

Does the system produce water puddles on the floor?

Nope. Water output's tiny vapor. Humid spots might condense a bit, but robots have evap trays to keep floors dry.

What maintenance does a hydrogen fuel cell require?

Maintenance is light but key: swap air filters (dust shield), check coolant, eye the fuel port. Easier than babying lead-acid batteries.

At what fleet size does hydrogen become viable?

Hydrogen shines for 15-20+ bot fleets in 24/7 shifts. Tiny 1-5 bot single-shift ops? High-end Li-ion wins on cost.

What's the storage pressure for hydrogen on the robot?

For material handling equipment, hydrogen's stored at a standard 350 bar (roughly 5,000 psi). The tanks are rugged Type 3 or Type 4 composite cylinders, built to shrug off major impacts and ace crash tests that blow past your typical warehouse bumps.

Can the robots refuel themselves autonomously?

Right now, most hydrogen refueling happens manually by an operator and takes about 2 minutes. But automated robotic refueling arms are in development and testing, unlocking fully autonomous 'lights-out' operations.

How does H2 perform in "Stop-and-Go" operations?

Spot on! Our hybrid setup (fuel cell + battery buffer) is tailor-made for this. The battery jumps in for those instant torque surges from starting or lifting, while the fuel cell keeps it charged and handles steady loads for seamless performance.

Is "Green Hydrogen" available for these robots?

You bet. Gray hydrogen from natural gas is the norm, but you can opt for green hydrogen made via electrolysis powered by renewables. That lets your robotic fleet run with a genuine zero-carbon footprint from well to wheel.