Harmonic Drive Gears

Unlock insane precision and torque in your AGV fleet with harmonic drive tech. These gears deliver zero-backlash performance that's perfect for cutting-edge navigation and robotic handling.

Core Concepts

Strain Wave Principle

Unlike stiff gears, harmonic drives use elastic deformation of a metal cup (the flexspline) to transfer motion, unlocking some pretty unique perks.

Zero Backlash

The gear teeth stay preloaded against each other nonstop, wiping out any gap. That means zero backlash and pinpoint positional accuracy.

High Torque Density

With tons of teeth (often 30% of them) meshed at once, they pack massive torque into a tiny package.

Compact Footprint

Coaxial setup aligns input and output on one axis, shrinking the space needed in robot joints or AGV wheels.

High Reduction Ratios

Get single-stage ratios from 30:1 to 320:1—no bulky gear trains—ideal for turning fast motor spin into real-world torque.

Reliability & Life

Even with the flexy parts, they're built for long life under rated loads, delivering reliable performance in industrial robotics.

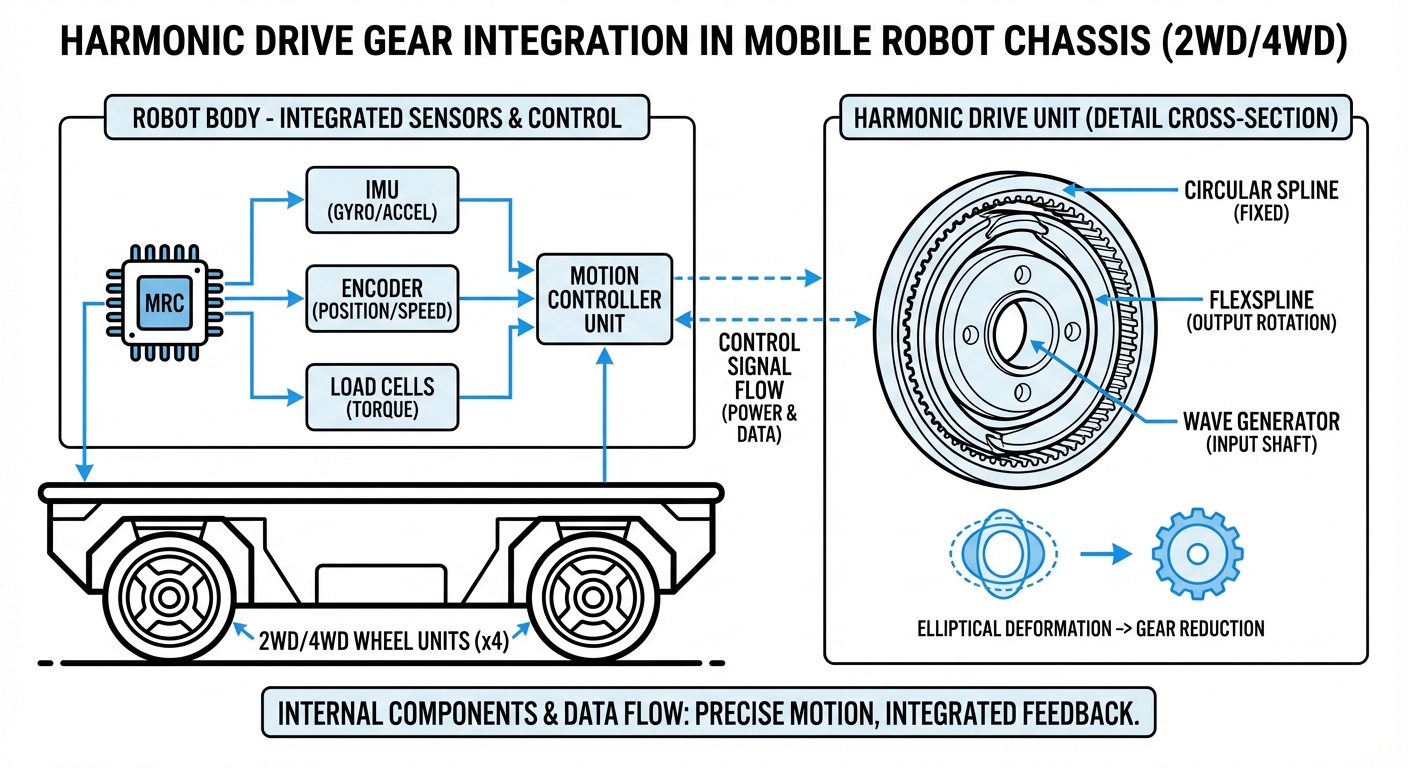

How It Works: The Three Components

A harmonic drive has three core pieces: Wave Generator, Flexspline, and Circular Spline. The Wave Generator's an elliptical cam that slips inside the Flexspline, forcing it into an oval shape.

As it spins, Flexspline teeth mesh with Circular Spline teeth along the ellipse's long axis. With two fewer teeth on the Flexspline, one full Wave Generator turn shifts it back exactly two teeth.

That mismatch gives huge reduction in one stage. Teeth roll in smoothly, so it's whisper-quiet, super smooth, and free of slop from spur or planetary gears.

Real-World Applications

Precision AGV Steering

Harmonic drives shine in omnidirectional AGV steering, nailing exact wheel angles to squeeze through tight warehouse aisles collision-free.

Mobile Manipulators (Cobots)

On AGVs with arms, they provide lightweight joint torque for millimeter-precise pick-and-place.

Heavy-Lift Jacking Units

For under-ride AGVs lifting racks, their torque density enables compact screws that hoist thousands of kilos smoothly and safely.

Medical Transport Robots

Hospitals demand quiet ops—the silky tooth contact in harmonic gears cuts noise way down versus planetaries, perfect for patient areas.

Frequently Asked Questions

What's the biggest edge of a Harmonic Drive over a Planetary Gearbox?

Zero backlash and higher single-stage ratios. Planetaries rock efficiency and load sharing, but Harmonics nail positioning accuracy and compactness—key for precision robotics and steering.

How does "Zero Backlash" affect AGV navigation?

Zero backlash means your steering command hits the exact spot, no slop or dead zone. Better path tracking, less wobble, tighter docking at chargers or conveyors.

Are Harmonic Drives suitable for high-speed applications?

Generally, no. They're torque champs at low speeds. Inputs top out at 3,500–6,000 RPM by size, but high ratios keep outputs slow. Great for joints and steering, less for high-speed drive wheels.

What is "Ratcheting" and how do I prevent it?

Ratcheting happens when overload makes Flexspline teeth skip over Circular Spline ones, risking damage. Avoid it with torque limiters or motor current caps below the 'Ratchet Torque' rating.

Do Harmonic Drives require special lubrication?

Yes, lube is key for the sliding teeth and flexing spline. They ship pre-greased with harmonic-specific stuff like SK-1A or 4B No.2. Wrong grease tanks lifespan and efficiency.

What is the typical efficiency of these gears?

Efficiency hits 70-90%, below planetaries (>95%). It dips in cold temps or light loads, so factor that into robot battery sizing.

Can Harmonic Drives handle shock loads?

They're shock-sensitive thanks to the thin Flexspline. They take peaks fine, but repeated crashes can bend it. Use soft-starts and collision sensors.

How long do Harmonic Drive gears typically last?

Lifespan hinges on Flexspline fatigue and Wave Generator bearing. Rated conditions give 7,000-10,000 hours L10 life—drop loads to stretch it further.

Are they back-drivable?

Yes, most are back-drivable—the output can turn the input. But friction's higher. For power-off holding (like arms), add an electromagnetic brake.

How does temperature affect performance?

In extreme cold, grease thickens up, cutting efficiency and ramping up the torque needed to get things moving. Scorching heat? It breaks down the lube entirely. For AGVs tackling cold storage (-20°C) or sweltering foundries, pick temperature-specific greases right at procurement time.

What sizes are available for AGVs?

You'll find sizes from super-small minis (3-5) for delicate grippers all the way to massive units (65+) for heavy-duty lifts. For AGV steering actuators, sizes 14 to 32 are the go-to sweet spot—plenty of torque without sacrificing compactness.

Is the hollow shaft design beneficial for robotics?

You bet. Plenty of harmonic drive sets come with a big hollow shaft (through-bore). Designers love routing cables, air lines, or even laser scanner wiring right through the center, keeping everything snag-free and shrinking the joint's rotation radius.