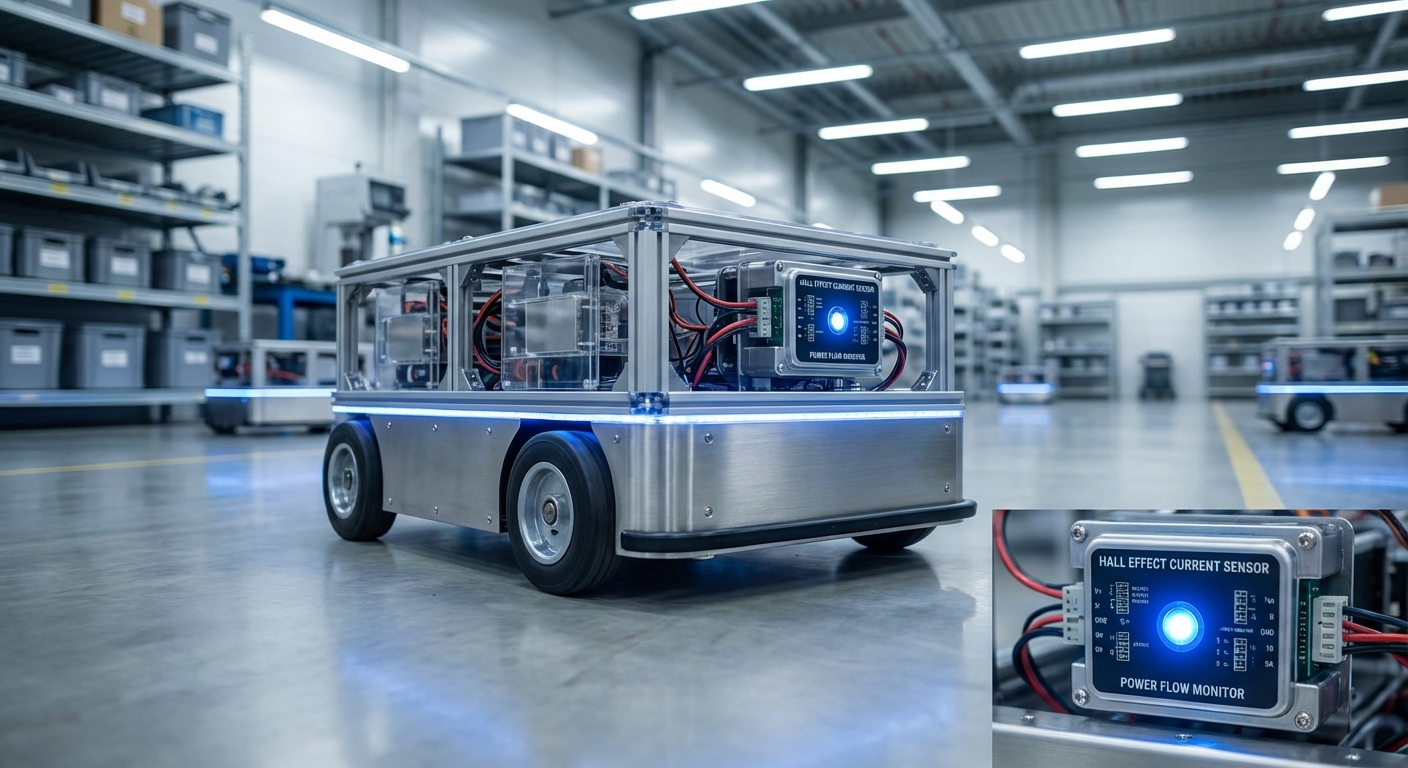

Hall Effect Current Sensors

Unlock spot-on power management and motor control for your autonomous mobile robots. These clever, non-intrusive sensors deliver key insights on battery health, payload weight, and safety— all without messing with electrical isolation.

Core Concepts

Galvanic Isolation

Unlike shunt resistors, Hall sensors don’t touch the current path at all. They keep high-voltage motor circuits safely away from your sensitive microcontroller.

Lorentz Force Principle

It taps into the magnetic field from current flow to generate a voltage across a conductor—giving you a straight-up link between magnetic flux and amps.

Overcurrent Protection

Vital for AGV safety, they catch current spikes right away (like a jammed wheel) and slam the emergency stop before motors fry.

Bi-Directional Sensing

They handle current in both directions, ideal for tracking battery drain during runs and recharges at the dock.

Immunity to Dust

Solid-state and fully sealed, Hall sensors shrug off dust, shakes, and moisture in warehouses and factories.

Payload Estimation

By watching how much current it takes to get the robot moving, the system figures out payload weight and tweaks acceleration on the fly.

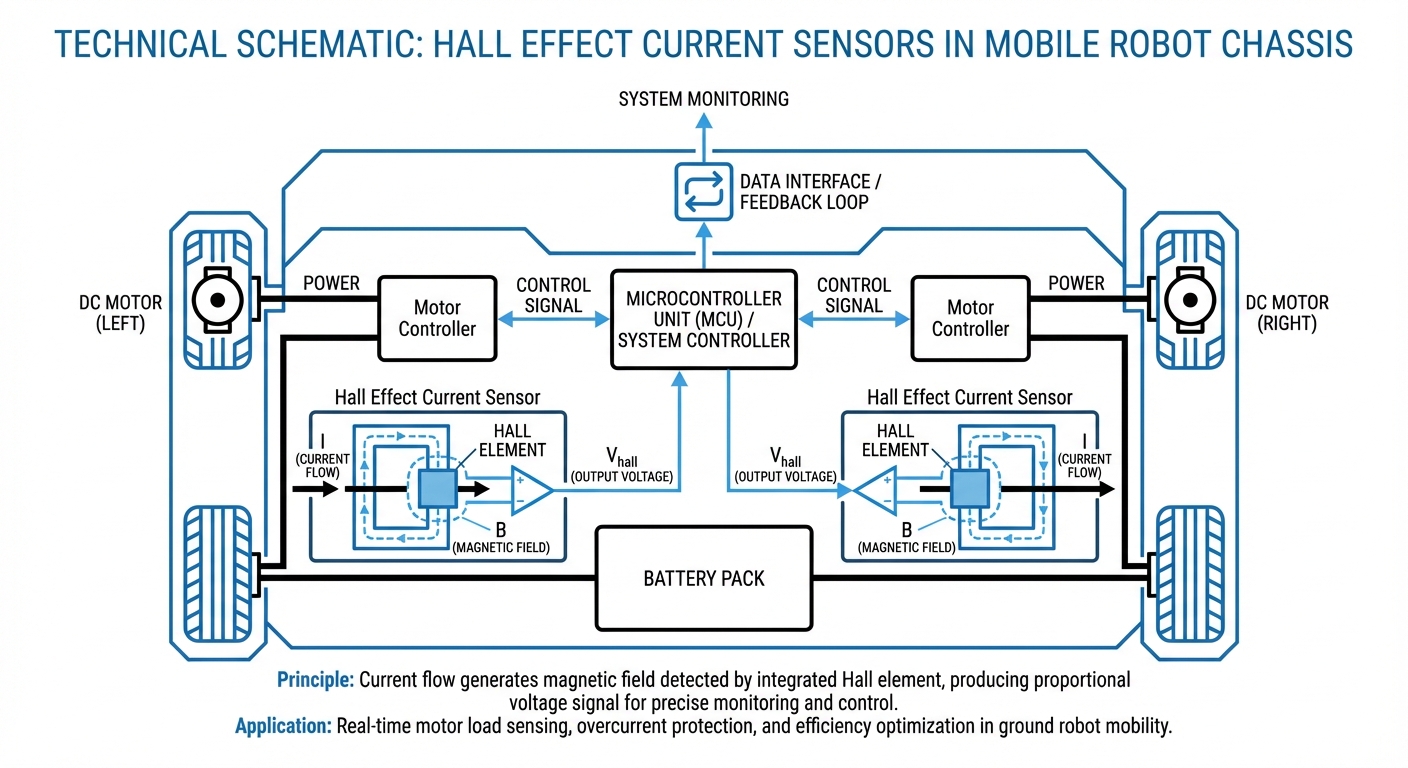

How It Works

At its core, a Hall Effect Current Sensor works by detecting the magnetic field from current in the main power wire to your drive motors.

As the current flows, it creates a magnetic field scaled to the amps. A semiconductor plate (the Hall element) sits right across from it. Run a bias current through the plate, and the magnetic field’s Lorentz force shoves the charges to one side.

That charge split produces a Hall Voltage across the plate. It’s a tiny analog signal that gets boosted and cleaned up for your robot’s MCU to read—turning raw electricity into useful digital info.

Real-World Applications

Predictive Maintenance

Tracking normal motor current over time lets Hall sensors spot rising resistance from worn bearings or dry lube, flagging maintenance before things break.

Collision Detection

In shared spaces, a sudden current surge means an obstacle hit. These sensors react quicker than bumpers, halting the robot on a dime.

Smart Battery Management

Precise Coulomb counting with Hall sensors nails State of Charge (SoC), so AGVs hit the charger right on time and keep fleets running maxed out.

Terrain Adaptation

Climbing a ramp? Current spikes, the sensor notices, and torque adjusts automatically to hold steady speed without bogging down.

Frequently Asked Questions

What’s the biggest edge of Hall Effect sensors over shunt resistors?

Galvanic isolation tops the list. They sense current through magnetic fields—no direct electrical link between high-power motor/battery lines and low-voltage controls. No nasty voltage spikes for your MCU, and no voltage drop like with shunts.

What’s the difference between Open-Loop and Closed-Loop Hall sensors?

Open-Loop ones just amp up the Hall voltage for output—they’re small, cheap, low-power, and perfect for battery AGVs. Closed-Loop use a feedback coil to null the field, delivering top accuracy, better linearity, and quicker response, but they guzzle more power and cost extra.

Do external magnetic fields affect the sensor's accuracy?

Yeah, big external magnets (like from nearby motors) can throw noise. But today’s Hall sensors use differential tricks or shielding to block stray fields, keeping readings spot-on in noisy factories.

Are these sensors good for both AC and DC current?

Yep, Hall Effect sensors nail both AC and DC. For AGVs, it’s DC for batteries and BLDC motors; AC comes in for onboard chargers tied to mains.

How does temperature affect Hall Effect sensor performance?

Hall elements can drift with temperature changes in offset or sensitivity. Top automotive-grade ones pack built-in temp compensation for steady accuracy from -40°C to +125°C.

What bandwidth do AGV motor controls typically need?

Basic battery watching? Low bandwidth works fine. But for tight BLDC vector control, aim for 50kHz to 100kHz to catch those zippy PWM waveforms and avoid shaky performance.

Can Hall sensors help in estimating the payload weight?

Totally. Measure the current to ramp up to a set speed on flat ground—the controller crunches that to peg total robot mass. More current for the same accel? Heavier load.

How do I hook up a Hall sensor to a microcontroller?

Most linear Hall sensors spit out an analog voltage around Vcc/2 (say, 2.5V on 5V). Just wire it to an ADC pin on your MCU. Newer ones even have I2C or PWM digital outs.

Do Hall Effect sensors degrade over time?

They're incredibly tough. As solid-state devices with no moving parts or wearing contacts (unlike potentiometers), they boast a super long lifespan—often outlasting the robot they're in.

What is the power consumption of these sensors?

They sip power, usually just 5mA to 15mA for open-loop sensors. That's tiny compared to an AGV's propulsion needs, making them perfect for non-stop monitoring.

How do I calibrate a Hall Effect current sensor?

Zero-current calibration means reading the sensor with no current flowing to nail down the offset. For gain, you run a known reference current through it and tweak the software's scaling to hit the expected output.

Do you need a PCB-mounted sensor or a split-core module?

For fresh designs, PCB-mounted sensors win for their compact integration. But retrofitting old robots? Split-core modules are a dream—they clip right onto existing cables without unplugging anything or breaking the circuit.