Feedforward Control

It's a smart control trick that lets Autonomous Mobile Robots (AMRs) predict what they need to do before mistakes happen. Feedforward acts ahead of the curve for smoother starts, sharper corners, and faster speeds in busy spaces.

Core Concepts

Proactive Action

Unlike feedback that waits for a goof-up to fix it, feedforward crunches a math model to nail the exact input needed right away for perfect motion.

Inverse Dynamics

The controller digs into "inverse dynamics" to grasp the robot's mass and inertia, figuring out the exact torque to get the AGV moving from a dead stop without any delay.

Disturbance Rejection

Feedforward shines at handling known hassles, like gravity on ramps or friction on different floors.

Latency Reduction

It skips the "check-compare-fix" loop of PID controllers, slashing phase lag so the robot feels super snappy.

Trajectory Tracking

Key for hugging paths. It keeps the AGV glued to curved routes without cutting corners or swinging wide.

Hybrid Architecture

Feedforward rarely flies solo – it's paired with feedback. Feedforward does the heavy lifting; feedback tweaks the tiny glitches.

How It Works

In a classic feedback setup like PID, the robot powers up, checks if it moved right, spots the error, and tweaks. That lag is baked in.

Feedforward Control flips this script.

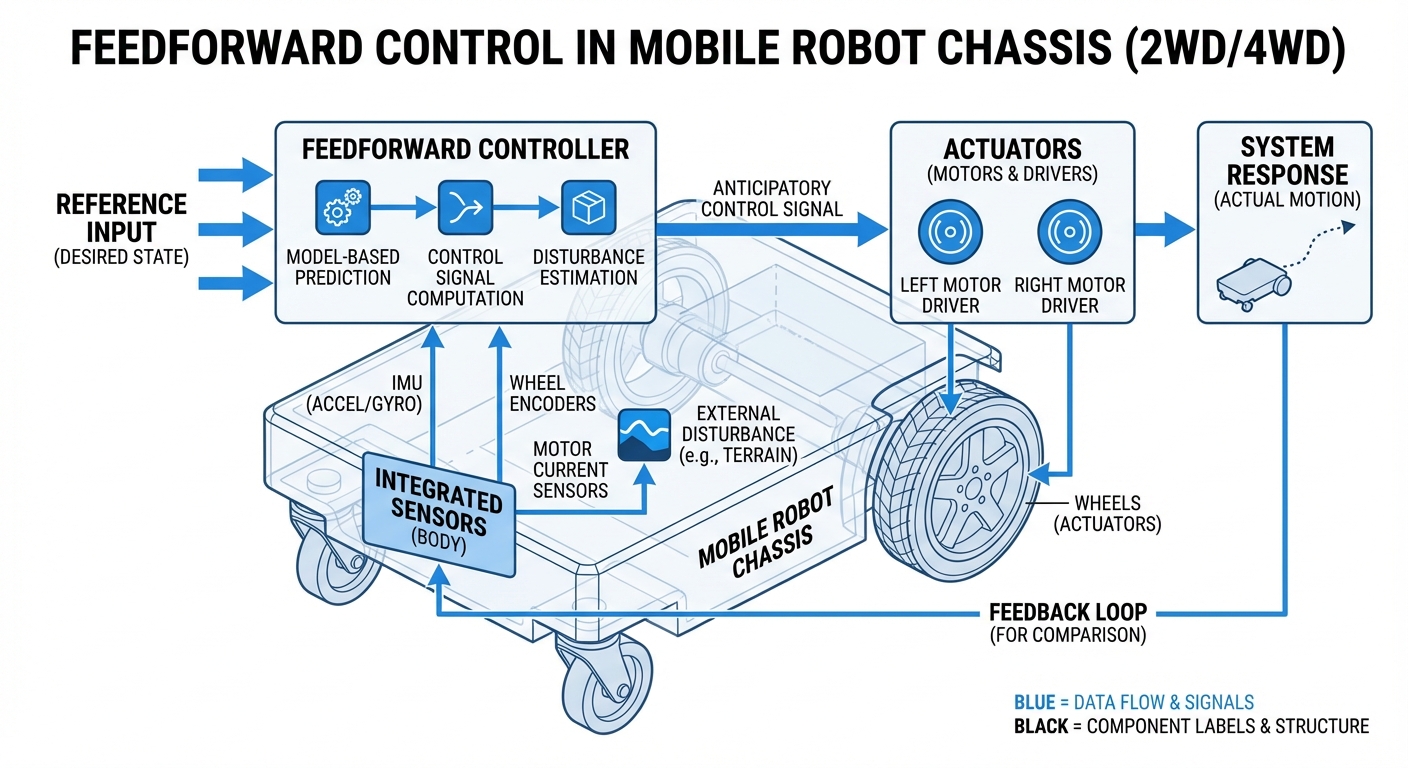

The diagram shows the flow: Reference trajectory hits the Feedforward block (Inverse Model) for instant control signals. Meanwhile, Feedback watches sensors for surprises like bumps or slips.

This duo makes a robot that snaps to commands instantly yet handles real-world chaos like a champ.

Real-World Applications

High-Speed Warehousing

In high-speed sortation hubs, AGVs corner fast. Feedforward counters centrifugal force to keep them on the magnetic tape or QR grid during tight turns.

Heavy Payload Transport

For AMRs hauling heavy pallets (1000kg+), inertia is huge. Feedforward computes the massive torque for smooth starts, avoiding jolts that could tip loads.

Ramp Navigation

Spotting a ramp? Feedforward kicks in "gravity compensation" to prevent slowdowns or rollbacks on inclines in multi-level spots.

Precision Docking

Docking to chargers or conveyors needs pinpoint accuracy. Feedforward nails deceleration to zero exactly on target, no bouncing.

Frequently Asked Questions

What's the big difference between Feedback and Feedforward control?

Feedback reacts to errors (gap between what you want and what happened) and fixes them. Feedforward predicts ahead with a model to deliver the perfect input before any error pops up.

Why can't I just use Feedforward control alone?

Feedforward banks on a spot-on math model. Reality throws curveballs like worn tires, shifting loads, or slick floors, so feedback mops up those small misses.

How does Feedforward control impact battery life?

Yeah, it boosts energy efficiency. No more power guessing and oscillating like in feedback loops – motors run smoother, less heat, less waste.

Is Feedforward control difficult to implement?

It takes more upfront work than tweaking PID, since you need system specs like mass, friction, and motor constants. But today's auto-tuning tools make it way easier.

Does Feedforward help with "lag" in robot movement?

Yep, especially phase lag. Feedforward jumps in the moment the target shifts, no waiting for errors to build, so motion matches commands almost perfectly.

What if the AGV's payload weight changes?

Big shifts without model updates mean sloppy performance (under- or overshoot). Smart AGVs use adaptive control or load sensors to tweak the mass in the feedforward math on the fly.

How does it handle friction?

Static and kinetic friction are tricky and non-linear for PID. Feedforward slips in a "friction compensation" boost to bust static friction smoothly at startup.

Does this require specialized hardware?

Nope, not really. It's just software running on your usual microcontroller or PLC. Needs decent floating-point math chops, though.

Can Feedforward prevent collisions?

Not straight-up. Feedforward is motor control, not safety nav. But quicker braking response can shorten stops, boosting safety indirectly.

What is "Velocity Feedforward" vs "Acceleration Feedforward"?

Velocity Feedforward tackles damping (speed-based friction), Acceleration Feedforward handles inertia (mass). They add up for total torque needs.

Is it cost-effective for small fleets?

Totally. Pure software means zero ongoing costs. Upfront modeling time pays off big in throughput and less wear.

How do I tune the Feedforward parameters?

Run "step response" tests: Log velocity without feedback, crunch inertia and friction from accel/decel curves, then plug into the controller.