EtherCAT Real-time Ethernet

EtherCAT gives AGVs microsecond sync across motion controls, safety gear, and nav systems. It's the gold standard for precise, fast, simple wiring in mobile robotics.

Core Concepts

Processing on the Fly

Unlike regular Ethernet, EtherCAT frames get handled on the fly by slave devices as they pass through. Data is read and written in an instant, wiping out communication delays.

Distributed Clocks

A rock-solid sync mechanism keeps all robot axes moving in perfect sync. Jitter drops below 1 µs, which is crucial for mecanum drive kinematics.

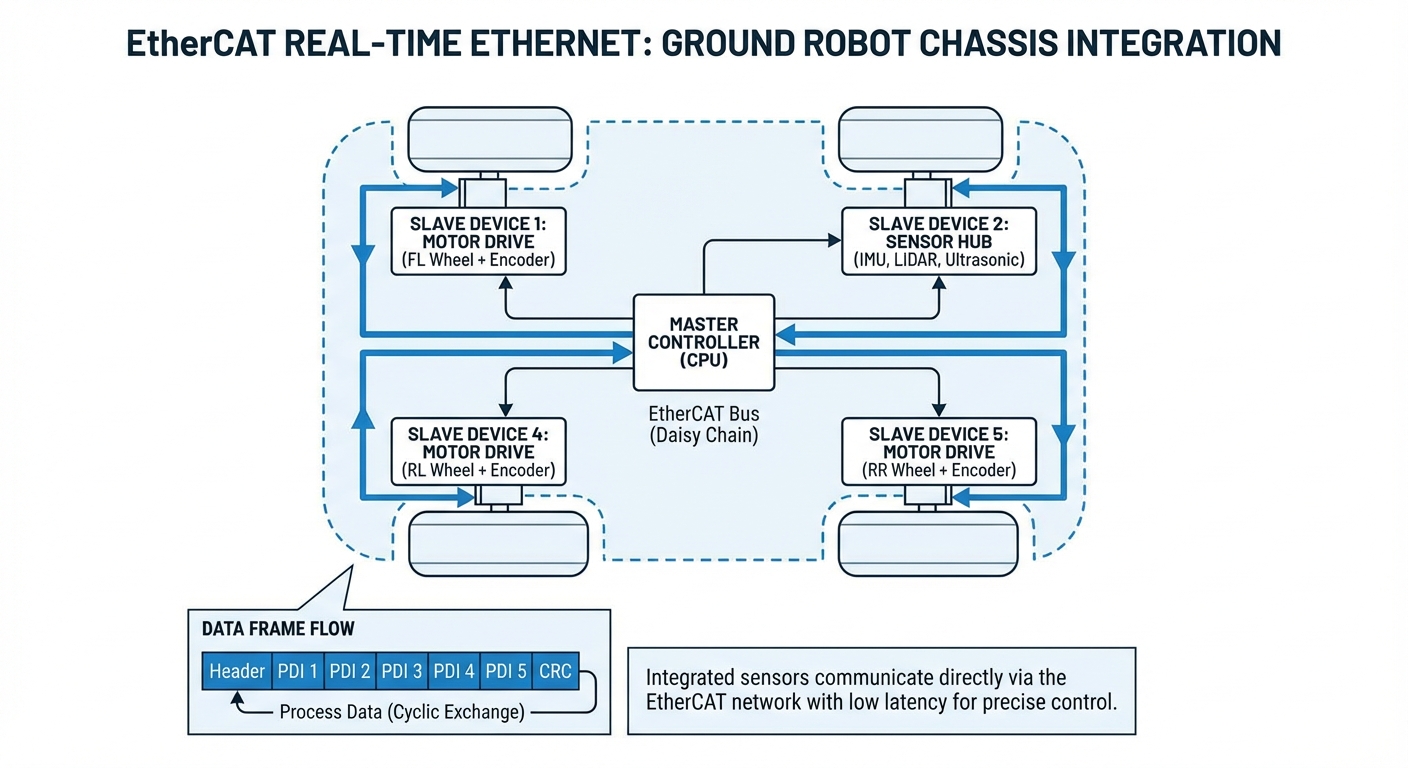

Flexible Topology

EtherCAT handles line, tree, and star topologies without any managed switches. That means you can daisy-chain devices right inside a tight AGV chassis, saving precious weight and space.

Safety over EtherCAT (FSoE)

Safety data—like E-Stops and LiDAR fields—travels over the same standard Ethernet cable as your control data, drastically simplifying wiring harnesses.

High Bandwidth Efficiency

EtherCAT squeezes over 90% out of the bandwidth. A single frame can refresh inputs and outputs for hundreds of devices, keeping bus cycle times incredibly low.

Cost Efficiency

Master devices just need a standard Ethernet port—no fancy cards required. Use everyday CAT5e cables, and skip expensive switches between nodes.

How It Works: The "Train" Analogy

Picture a high-speed train (the Ethernet frame) that never stops at stations. Passengers (data) hop on and off while it's flying at full speed. That's the magic of EtherCAT's "Processing on the Fly."

In a typical mobile robot setup, the Industrial PC (Master) sends out one frame. It races through motor drivers, I/O modules, and safety scanners (Slaves). Each device grabs its command and slips in feedback data—like motor encoder positions or battery voltage—into the same frame.

The frame loops back to the Master with a full snapshot of the robot's state. This happens thousands of times per second (often 1kHz to 8kHz), letting the robot react instantly to surprises, like a person stepping into its path.

- Single frame for all devices

- Full duplex communication

- Deterministic timing

Real-World Applications

Precision Docking & Charging

AGVs need millimeter precision to dock with chargers or conveyors. EtherCAT's super-fast feedback loop lets the navigation controller tweak wheel motors on the spot for perfect alignment every time.

Holonomic Motion Control

Mecanum or Swerve drive robots need four or more motors in flawless coordination for diagonal moves or spot rotation. Distributed Clocks deliver velocity commands to every motor at the exact same microsecond, stopping slippage and drift.

Integrated Safety Zones

Safety over EtherCAT (FSoE) lets safety laser scanners talk directly to the safety PLC and motor drives over the standard bus. Detect an obstacle? It triggers Safe Torque Off (STO) immediately—no separate wiring for each sensor.

Mobile Manipulation

For AMRs with robotic arms, EtherCAT syncs the mobile base perfectly with the arm controller. The base compensates for arm movements in real time, expanding the workspace and speeding up cycles.

Frequently Asked Questions

What distinguishes EtherCAT from standard TCP/IP Ethernet?

Standard TCP/IP is unpredictable—packet times vary, fine for browsing but risky for robot control. EtherCAT uses the same cables with a protocol that guarantees delivery in microseconds for true real-time performance.

Does EtherCAT require special cables or switches?

No. Standard CAT5e or CAT6 Ethernet cables work fine. EtherCAT skips standard switches—devices daisy-chain together, simplifying your BOM and cutting costs for AGV makers.

What is Safety over EtherCAT (FSoE) and why use it?

FSoE is a certified safety protocol running on the same wire as control data (Black Channel principle). Reach SIL 3 / PLe safety without extra yellow cables to every E-stop or scanner—saving tons of weight and space in mobile robots.

How does EtherCAT handle network topology changes?

EtherCAT's Hot Connect lets you plug or unplug network sections while it's running. Great for modular robots or AGVs swapping tools or trailers with their own I/O modules on the fly.

Can I use EtherCAT with ROS or ROS 2?

Yes, there are open-source and commercial EtherCAT masters for Linux that integrate seamlessly with ROS/ROS 2 (like SOEM or EtherLab). High-level navigation stacks can talk directly to real-time hardware drivers.

What is the maximum cable length between nodes?

Like standard Ethernet, EtherCAT nodes can span up to 100 meters (328 ft) on copper cable. AGV runs are usually short, but this reach shines for linking to fixed infrastructure via optical links.

What happens if a cable breaks or a device fails?

EtherCAT builds in cable redundancy. Wire the last node back to a second master port for a ring topology. Cable fails? Traffic reroutes instantly, letting the robot keep going or shut down safely.

Is EtherCAT suitable for battery-powered devices?

Yes. EtherCAT slave controllers run in hardware (ASICs or FPGAs) and sip power compared to CPUs handling TCP/IP stacks. It helps stretch your AGV's battery life.

How many devices can be connected to one Master?

EtherCAT supports up to 65,535 nodes per segment in theory. For AGVs, you'll never hit that cap—just pack in as many sensors, drives, and I/O modules as your chassis allows.

What is the typical cycle time for an AGV application?

Mobile robotics typically sees cycle times from 1ms (1kHz) to 4ms (250Hz)—plenty for smooth control and navigation. High-end arms on AGVs can hit 250µs (4kHz).

Do I need a specific hardware card for the Master?

No. EtherCAT masters are pure software, running on any standard Ethernet controller in industrial PCs (Intel or Realtek chips). Only slaves need dedicated EtherCAT hardware.

Ready to implement EtherCAT Real-time Ethernet in your fleet?

Take your AGV to the next level with our compliant hardware solutions.

Explore Our Robots