Cycloidal Drives

Level up your mobile robots' precision and toughness with cycloidal gearing. It's a game-changer for heavy-duty AGVs needing massive torque in a tiny package, zero backlash, and bomb-proof shock handling.

Core Concepts

High Torque Density

Cycloidal drives pack one of the best torque-to-weight punches out there. Multiple teeth share the load at once, so compact boxes haul huge AGV payloads.

Shock Load Resistance

Unlike planetary gears that can snap under shock, cycloidals shrug off spikes up to 500% of rated torque—perfect for hard stops.

Zero Backlash

Get razor-sharp positioning with almost no play (< 1 arcmin). Essential for AGVs docking perfectly or robot arms grabbing just right.

Rolling Contact

It's all rolling action, no sliding friction. That cuts wear, kills heat buildup, and stretches service life way longer.

Compact Profile

Their slim 'pancake' shape fits right into wheel hubs or joints, freeing up chassis room for batteries and sensors.

High Reduction Ratios

Score huge reduction ratios like 100:1 in one stage, no extra length—ideal for slow, mighty AGV moves with simpler drivetrains.

How It Works

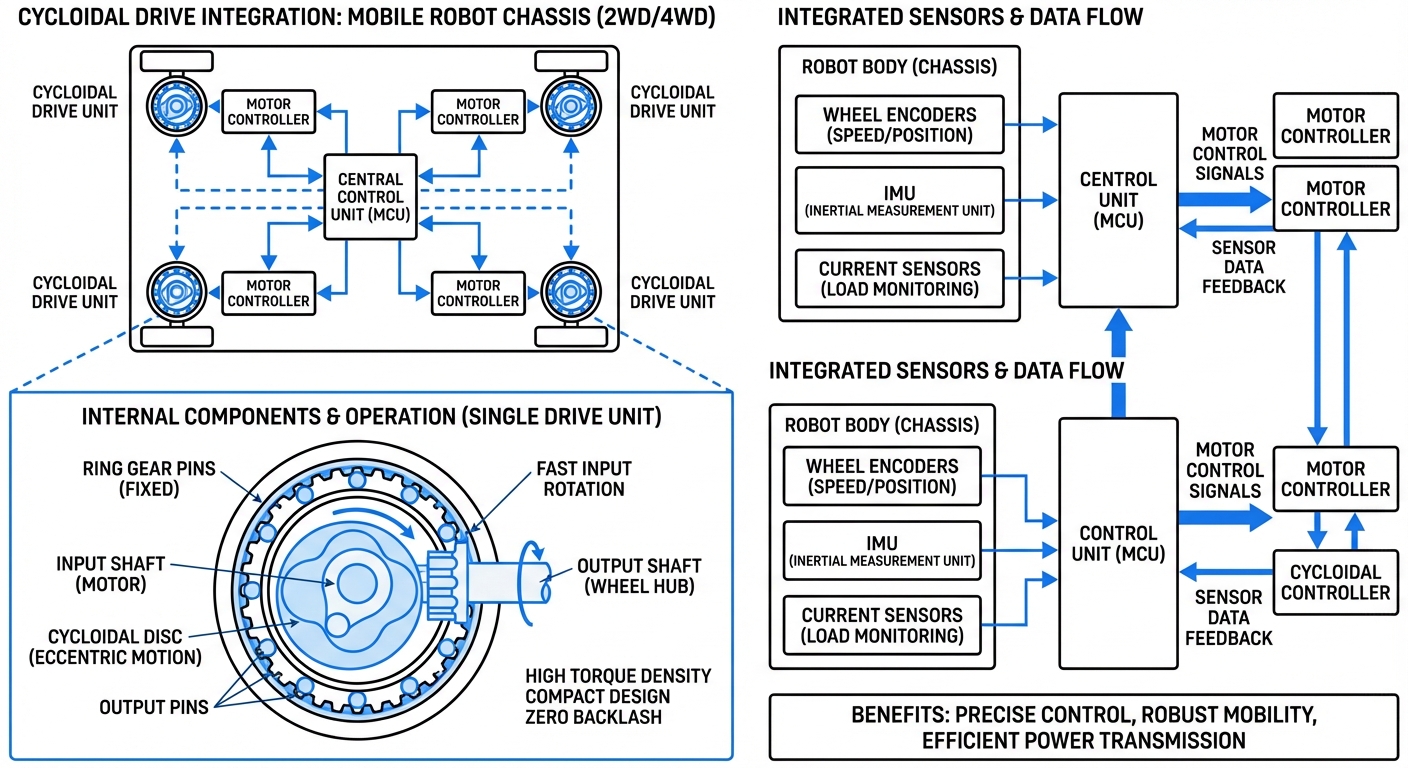

The secret sauce in a cycloidal drive? Its quirky eccentric dance. Skip the usual gear teeth: an input shaft spins an eccentric bearing that wobbles a cycloidal disc inside a pin-lined housing.

As the shaft turns, the disc wobbles around the housing's edge. With one fewer lobe than pins, it creeps backward at reduced speed—boom, huge single-stage reduction.

Then, output pins in the disc's holes grab that slow spin, ditching the wobble for smooth, powerful rotation at the shaft.

Result:

Real-World Applications

Heavy-Payload AGVs

In car factories and warehouses, AGVs lugging 1,000kg+ pallets cram cycloidals into wheel hubs. They soak up shocks from floor seams or bumps under heavy loads.

Surgical & Medical Robots

Where every micron counts, like surgical robots, cycloidals deliver zero-backlash smoothness—no vibrations, just steady precision.

AMR Tuggers

Tuggers yanking cart trains need monster startup torque against friction. Cycloidals' steep ratios deliver it without giant motors.

Collaborative Robot (Cobot) Joints

Mobile manipulators (arms on AGVs) tuck flat cycloidals in elbows and wrists. Lighter arms mean longer battery life for the base.

Frequently Asked Questions

What sets cycloidal drives apart from planetary gearboxes?

It's all about contact: planetaries slide and roll teeth, stressing roots and snapping under shocks. Cycloidals roll over huge areas (30% of lobes at once), crushing shocks with top-tier torque density.

Why are Cycloidal Drives preferred for AGV wheel hubs?

That pancake profile slips the gearbox inside the wheel rim, slimming the AGV. Constant starts, stops, and reverses? Cycloidals handle it without growing backlash, keeping paths dead-on.

What does "Zero Backlash" mean in a practical context?

Backlash is that annoying gear slop—if you fix the input and jiggle the output, it wiggles. Cycloidals? Under 1 arc-minute lost motion. Your AGV docks at the charger, wheels stay put, connections click perfectly every time.

How does the efficiency compare to other gear types?

Expect 85-90% efficiency per stage from cycloidals. Premium planetaries hit 95%, but for robots, it's worth it—cycloidals nail 100:1 in one go, while planetaries need two stages and matching efficiency.

Are there maintenance requirements for these drives?

Robotics cycloidals ship sealed with lifetime grease. Heavy-duty constant-speed jobs might need oil baths and checks. They fail from surface pitting (with warning), not sudden breaks.

What is the "500% Shock Load" capacity?

This safety factor means the drive can handle a sudden torque spike—up to five times its rated torque—without any structural damage. It's a game-changer for mobile robots that might crash into obstacles or hit an Emergency Stop (E-Stop), where the load's momentum tries to violently back-drive the gearbox.

Can cycloidal drives be back-driven?

High-ratio cycloidal drives (above 30:1) are tough to back-drive thanks to internal friction and mechanical advantage. They work like a passive brake, keeping AGVs steady on gentle inclines even without power. That said, they're not fully self-locking like some worm gears, so grab a dedicated electromechanical brake for extra safety.

Are they compatible with standard servo and stepper motors?

Yep. Manufacturers include adapter plates and clamping couplings to hook up with standard NEMA or metric servo motor shafts. The input shaft is built for high RPMs (up to 4000-5000 RPM) from today's brushless DC motors.

How does temperature affect performance?

Temperature changes the lubricant's viscosity and makes internal parts expand or contract. Cycloidal drives run on super-tight tolerances, so extreme cold ramps up drag (tanking efficiency), while heat breaks down the grease. Standard range is -10°C to +40°C, but special greases handle freezer warehouses or scorching foundries.

Is vibration an issue with the eccentric motion?

Modern cycloidal drives often use a dual-disc setup with discs offset 180 degrees apart. This clever design cancels out vibrating forces for buttery-smooth, vibration-free performance—even at high speeds. Perfect for camera robots or hauling sensitive gear.

What is the cost comparison vs. Harmonic Drives?

Both deliver zero backlash and high ratios, but harmonic (strain wave) drives rely on a flexible spline that's more fragile and packs less torque for the size. Cycloidals are rugged and budget-friendly for heavy traction jobs, while harmonics excel in ultra-light, low-torque robot joints.

What happens if a cycloidal drive fails?

Failure tends to be gradual, not a sudden boom. Rolling fatigue leads to pitting on the race surfaces, cranking up noise and vibration. Unlike a gear tooth snapping and locking the whole gearbox, a wearing cycloidal drive keeps chugging (noisily), so your AGV can limp back to maintenance instead of getting stuck.