Automated Battery Swapping

Ditch charging downtime and supercharge your fleet with automated battery swaps. Swap dead packs in minutes for near-100% AGV/AMR uptime in busy factories.

Core Concepts

Zero Downtime

Swapping's 2-3 minutes vs hours of plugged-in idling. Robots stay hustling, boosting shift output.

Fleet Optimization

Shrink your fleet—no 'backup' chargers needed. Fewer bots handle the same work sans charge time.

Battery Health

Batteries charge smartly in racks at ideal rates, living longer than on-bot fast charges.

Mechanical Precision

Precision actuators and rails make it happen. AGV docks, arm yanks the old battery and slots in a fresh one.

Modular Design

Universal cassettes mean all your robot types share stations, simplifying your setup.

Energy Cost Savings

Stations charge off-peak, banking power for peak-time swaps.

How It Works

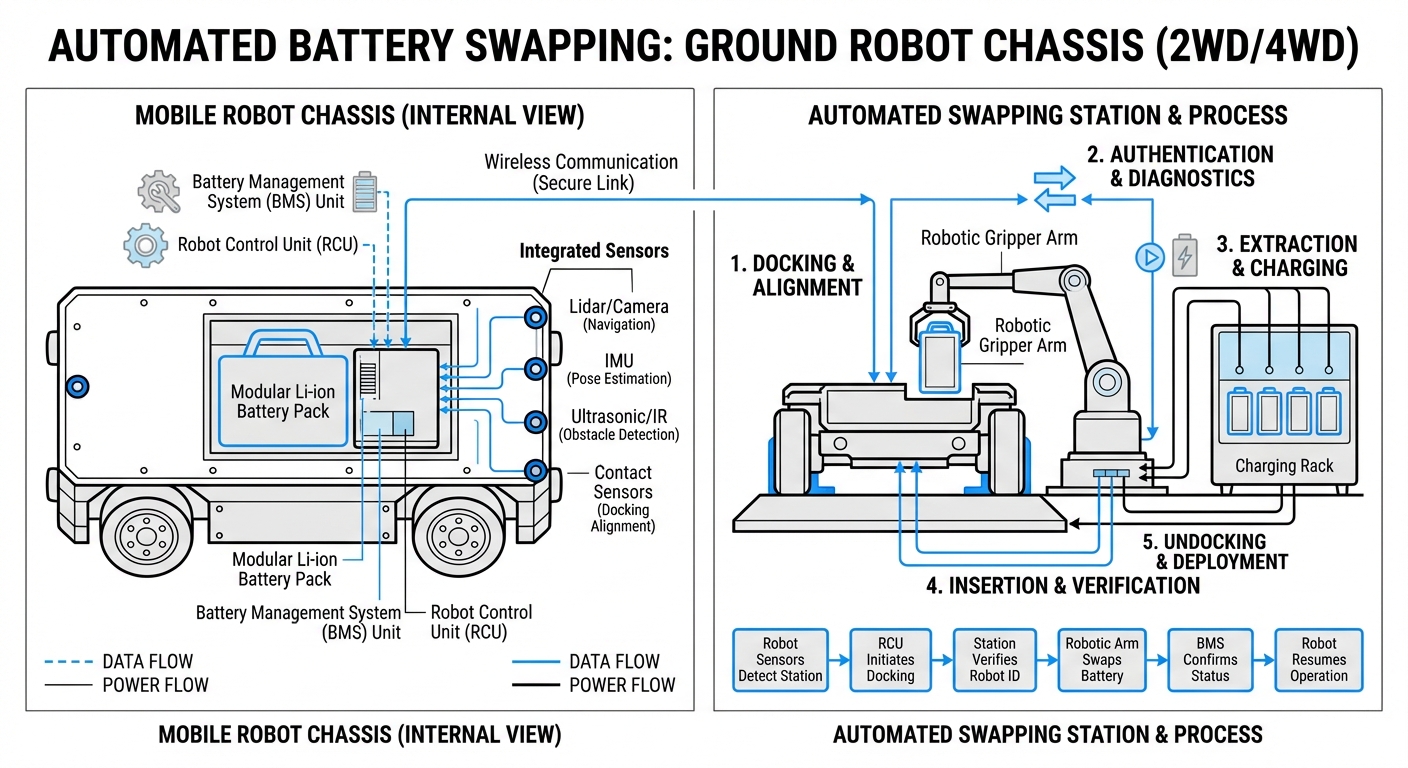

A central Fleet Management System (FMS) runs the whole automated battery swapping show. When an AGV's Battery Management System (BMS) spots the charge dropping below a set threshold—usually around 20%—the FMS directs the robot straight to the nearest available swapping station.

Once it arrives, the AGV taps into its LiDAR and optical sensors for sub-millimeter docking accuracy. Safely locked in, the station's electromechanical actuator releases the battery latch, slides out the drained module onto a charging rack, and swaps in a fully charged one from its stock right away.

The swap happens seamlessly without shutting down the robot's onboard computer, thanks to an internal capacitor or small backup battery that keeps logic states alive. This 'hot-swap' magic lets the robot jump right back into its tasks the moment it undocks.

Real-World Applications

24/7 E-commerce Fulfillment

In giant fulfillment centers, robots pick orders non-stop. Battery swapping enables 'lights-out' operations, so they skip long charging breaks even during peak seasons.

Automotive Assembly Lines

AMRs hauling parts to assembly lines can't handle delays. Swapping keeps those line-side deliveries perfectly in sync with the manufacturing process's Takt time.

Cold Chain Logistics

Batteries wear out fast and charge poorly in sub-zero temps. Swapping lets you warm up and recharge depleted packs in a cozy separate room before sending them back into the freezer aboard a robot.

Hospital Material Transport

Hospitals have super-tight hallways with no room for charging stations. Tuck swapping stations in the basement instead, and AMRs keep gliding along with linens and meds, no obstructions.

Frequently Asked Questions

What is the primary advantage of swapping over "opportunity charging"?

The big win is speed and better use of your robots. Opportunity charging ties them up idle for 15-30 minutes multiple times a day. Swapping refreshes the battery in under 3 minutes, letting one robot handle the workload of 1.2 to 1.5 that depend on charging.

Does the robot turn off during the swap?

No. Most modern swapping systems use a small internal capacitor or secondary "bridge" battery. This keeps the onboard computer, navigation stack, and communication modules humming along, so the robot skips any reboot or re-localization after the swap.

How much space does a swapping station require?

Swapping stations take up more space than basic charging mats since they store, charge, and mechanically handle multiple battery packs. A typical one needs about a 2m x 2m footprint, depending on how many spares it holds.

Are the mechanical parts prone to failure?

Sure, swapping involves more moving parts than contact charging, but today's stations rock industrial-grade actuators good for hundreds of thousands of cycles. You do routine maintenance on the station, but it's way less hassle than fixing worn charging contacts on every single robot.

What types of batteries are compatible?

Swapping systems are usually proprietary or built around specific modular standards (like VDA 5050 extensions). They pack high-density Lithium-Ion (Li-ion) or Lithium Iron Phosphate (LiFePO4) batteries into tough casings with custom handles for the swapping mechanism.

How does swapping extend battery life?

Fast-charging right on the robot builds up heat that kills battery cells over time. Swapping offloads depleted packs to the rack for slow, temperature-controlled charging—which can double the battery's cycle life.

What docking precision is required?

Precision is everything. Robots need to dock within +/- 5mm. They nail it with floor QR codes, station vision systems, and mechanical funnels that guide and center them as they slide in.

Is this solution cost-effective for small fleets?

Generally, no. The upfront cost (CAPEX) for those fancy stations is steep. Swapping pays off for bigger fleets (10+ robots) or 24/7 ops, where buying extra robots to cover charging downtime costs more than the swapping setup.

What happens if a swap fails?

Stations have smart error-handling. If a swap glitches (like a jam), it pings the fleet manager. The robot usually keeps its old battery (if not ejected yet) and gets rerouted to a manual charger or backup station.

Can one station serve different robot types?

Only if the robots use the same battery module standard and interface height. Cross-compatibility is the dream, but right now, most are vendor- or model-specific.

Is there a safety risk with exposed contacts?

Safety comes from physical shields and software interlocks. High-voltage contacts stay recessed and only power up after the battery handshake confirms a solid connection—no arcing or shocks.

How does the system handle "old" batteries?

The station's BMS monitors State of Health (SoH) for every rack battery. Hit a capacity threshold like 80%, and it gets flagged for service or recycling, never swapped back into a robot.