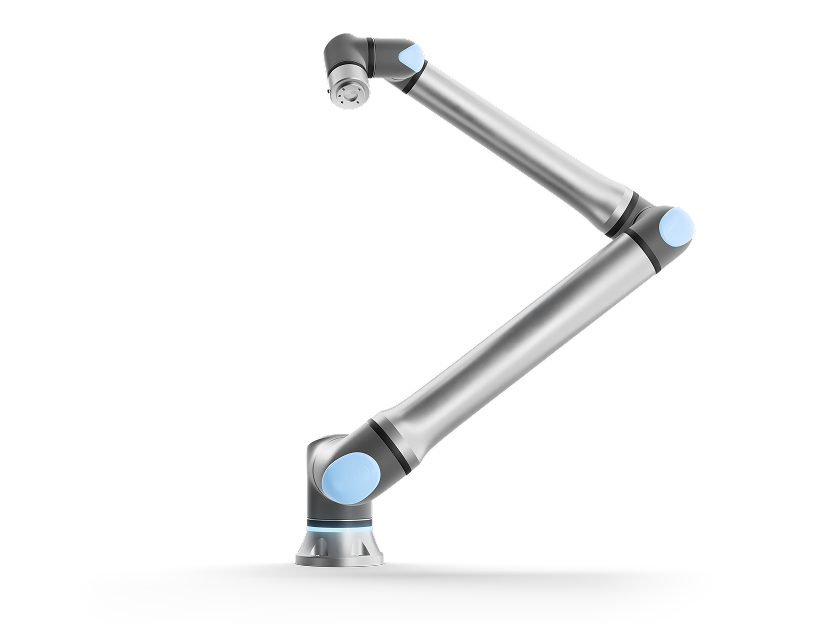

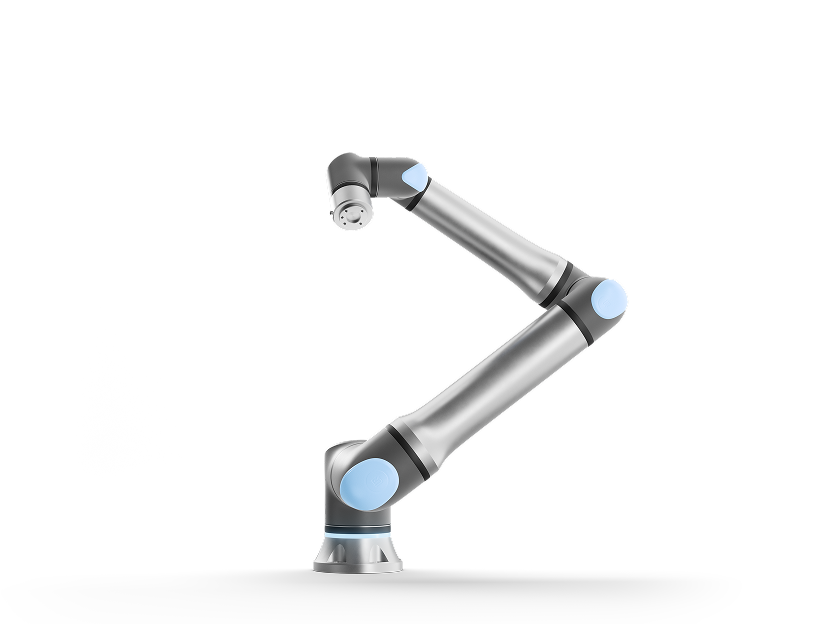

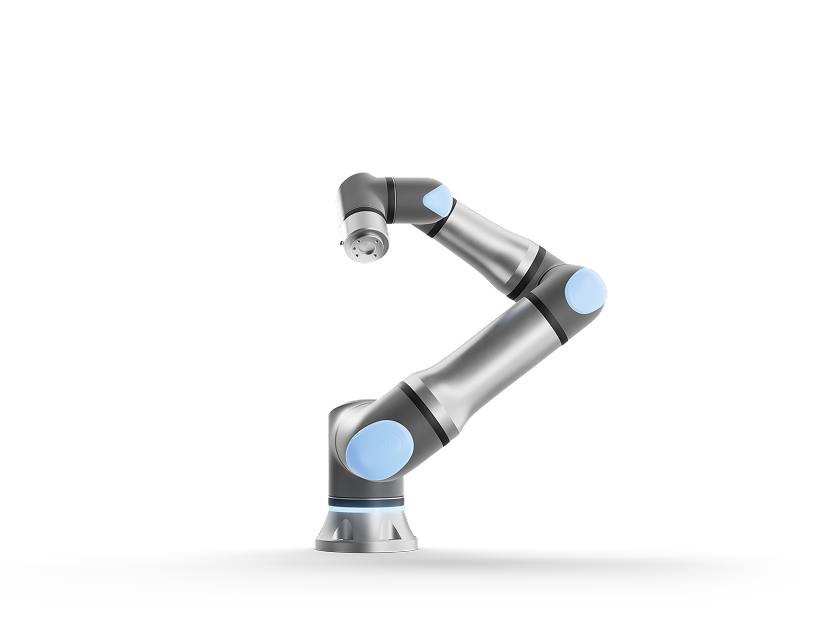

UR5e

UR5e is the e‑Series all-rounder, striking the perfect balance of reach, payload, and size for all sorts of automation jobs. With 5 kg payload and 850 mm reach, it handles workspaces with conveyors, assembly jigs, test benches, and packing lines effortlessly. Lots of folks start with UR5e as their first cobot, then carry over the same skills and tools to future setups.

Image Gallery

Specifications

Payload

5 kg

Reach

850 mm

Degrees of Freedom

6 rotating joints

Robot Mass

≈ 20 kg class

Repeatability

≈ ± 0.03 mm (e‑Series spec)

Base Footprint

≈ Ø 149 mm

Integrated Force Torque Sensor

Yes, 6-axis at tool flange

Power Consumption Max

≈ 570 W

Power Consumption Typical

≈ 200 W

Operating Temperature

0–50 °C

Protection Rating

Industrial IP level suitable for typical factory conditions

Programming Interface

PolyScope on 12" touchscreen plus URScript

Safety Functions

Up to 17 customizable safety options, like safety planes and joint limits

Typical Applications

Pick-and-place, assembly, testing, packaging, light machine tending, simple dispensing

Key Features

5 kg payload and 850 mm reach tackle a huge variety of handling and assembly tasks

Six-axis design for total orientation control around parts and fixtures

Built-in force/torque sensor for precise control and effortless hand-guiding

Tight repeatability suitable for detailed assembly and inspection tasks

Compact and lightweight, so it's easy to mount on carts, tables, or machine fronts

PolyScope offers drag-and-drop programming plus scripting for power users

Vast UR+ ecosystem of certified grippers, screwdrivers, vision kits, and software extras

Shared safety toolkit with adjustable zones, speed limits, and reduced-mode ops

Short deployment times thanks to templates and application-specific wizards

Scales effortlessly from low-volume prototypes to high-output multi-shift production

Product Description

UR5e is the e‑Series all-rounder, striking the perfect balance of reach, payload, and size for all sorts of automation jobs. With 5 kg payload and 850 mm reach, it handles workspaces with conveyors, assembly jigs, test benches, and packing lines effortlessly. Lots of folks start with UR5e as their first cobot, then carry over the same skills and tools to future setups.

Frequently Asked Questions

UR5e’s payload and reach nail most everyday tasks, and its small footprint makes setup a snap. Teams can master one robot and apply that know-how everywhere.

Light enough to slap on mobile bases or wheeled carts, letting it jump between machines or lines weekly or across product runs.

Yes. Tons of UR+ certified gear—grippers, screwdrivers, cameras, software—plugs right in with simple interface blocks.

UR5e teams up great with 2D/3D vision for bin picking, part orientation, and inspections, thanks to easy URCaps integration.

Set speed and force limits, add virtual walls, and create slow zones so the robot smartly adjusts when people get close.

Yes, UR5e handles tough industrial cycles and powers multi-shift lines for many makers—just stick to routine maintenance.