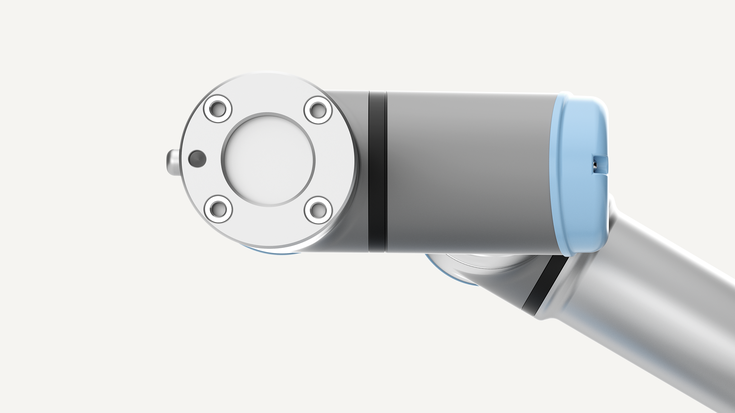

UR3e

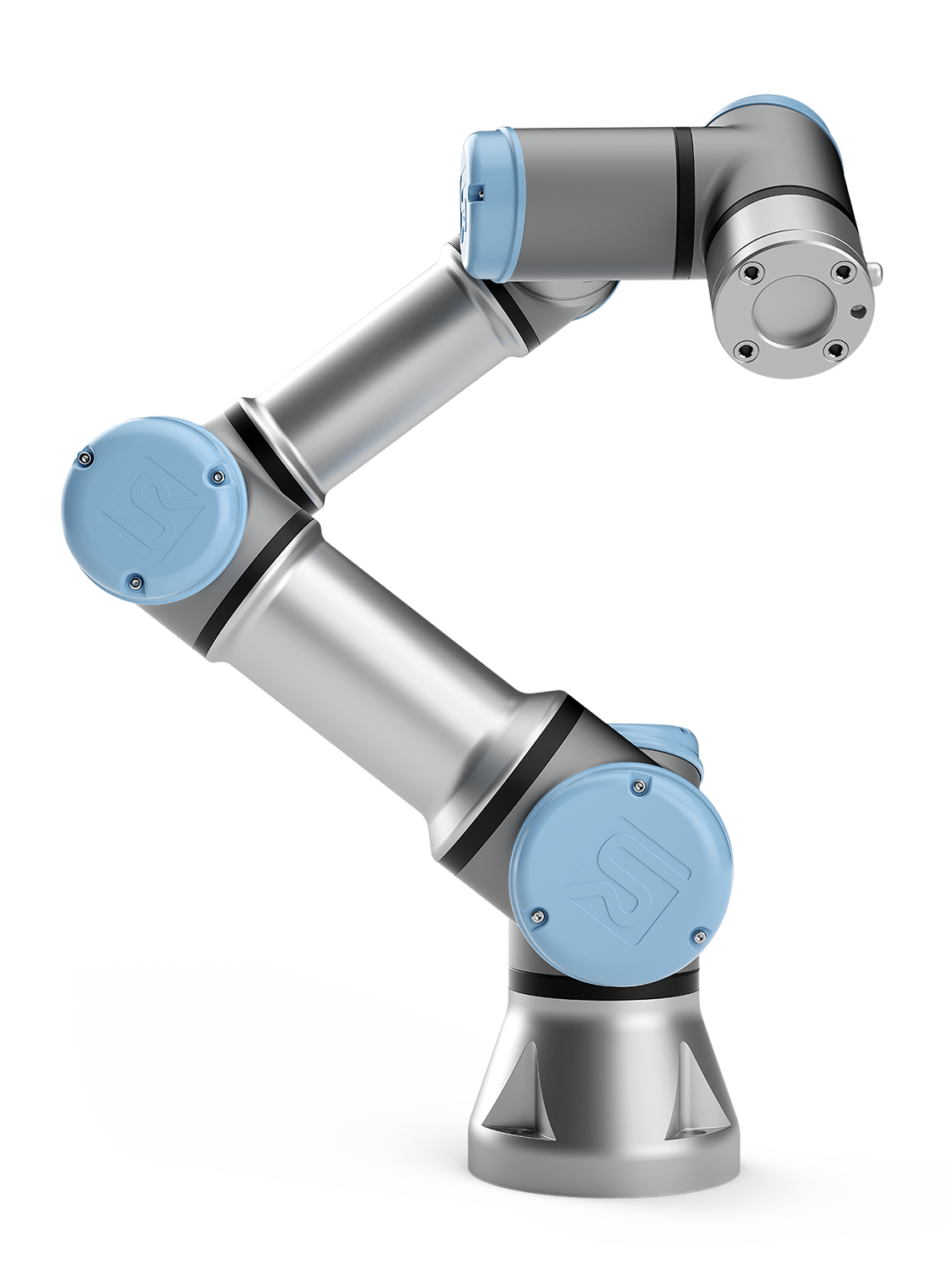

UR3e is the tiniest e‑Series member, made for right-on-the-bench tasks. Its 3 kg payload and 500 mm reach fit screwdriving, light assembly, testing, and lab work like a glove, and super-low weight means easy moves between stations. Small but mighty, it packs the same force sensing, safety, and programming as bigger siblings for seamless skill-sharing across the lineup.

Image Gallery

Specifications

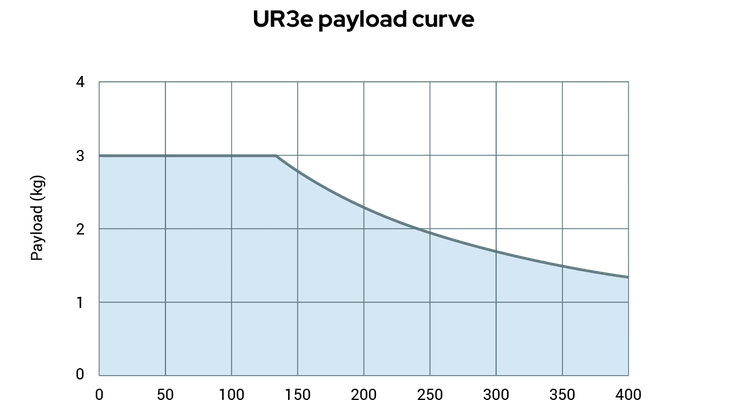

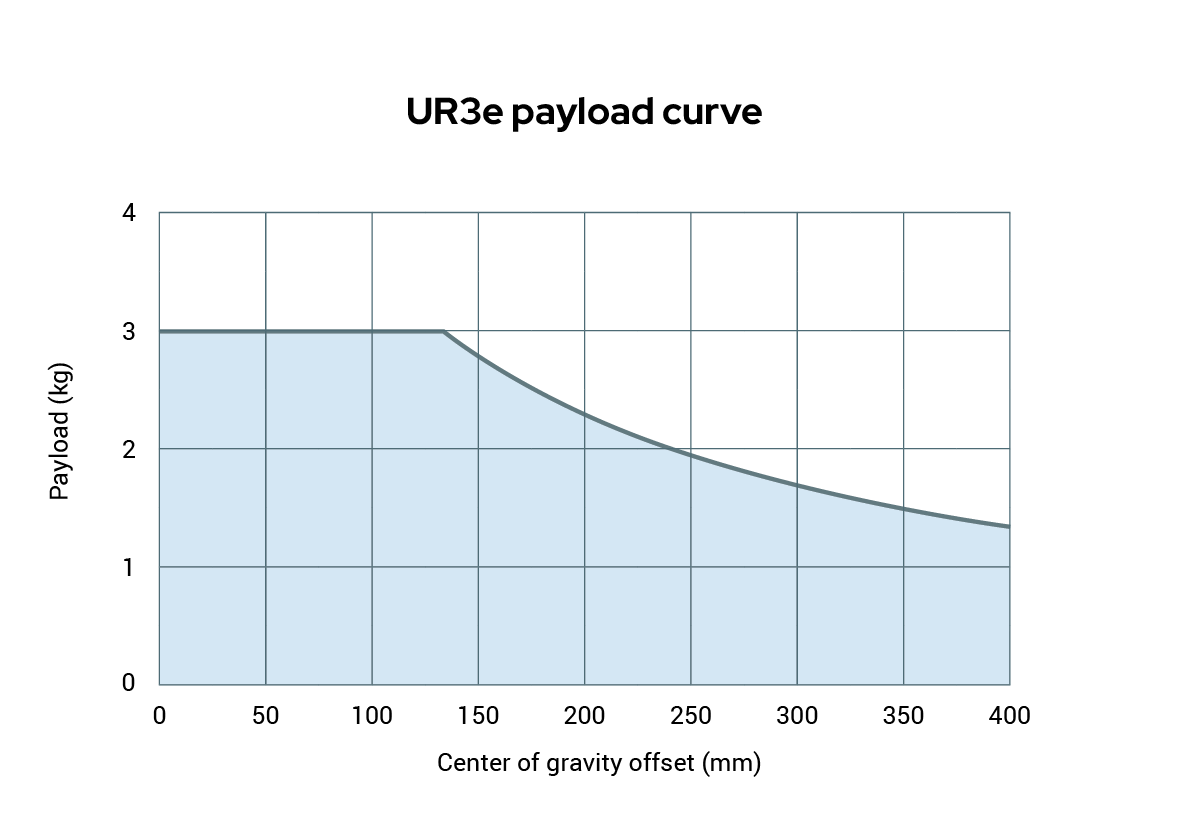

Payload

3 kg

Reach

500 mm

Degrees of Freedom

6 rotating joints

Robot Mass

≈ 11.2 kg

Repeatability

± 0.03 mm (typical e‑Series spec)

Base Footprint

≈ Ø 128 mm

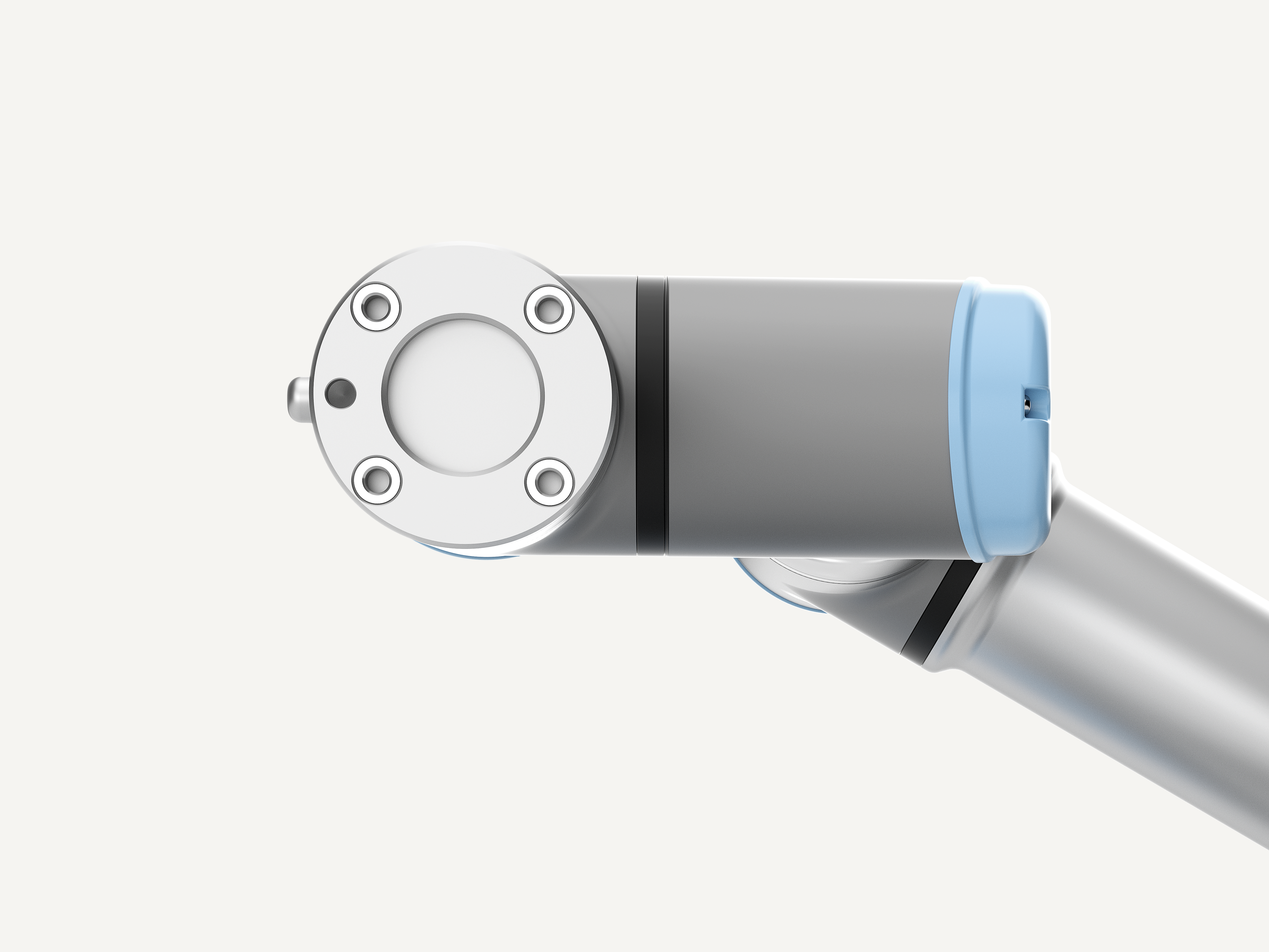

Integrated Force Torque Sensor

Yes, 6-axis at tool flange

Power Consumption Max

≈ 300 W

Power Consumption Typical

≈ 100 W at moderate settings

Operating Temperature

0–50 °C

Protection Rating

Industrial IP level suitable for typical shop environments

Programming Interface

12" touchscreen with PolyScope graphical UI and script language

Safety Functions

17 adjustable safety features (speed, force, zones, stop times, and more)

Typical Applications

Screwdriving, small-parts assembly, test setups, fixture loading, lab automation, gluing, dispensing

Key Features

Compact 6-axis cobot that saves space for benchtop jobs and tight cells

With a 3 kg payload and 500 mm reach, it's perfect for picking up small components and tools.

Its lightweight design means you can mount it right on tables, carts, or compact fixtures without any hassle.

It offers top-notch positioning consistency, making it ideal for precision assembly and testing jobs.

The built-in 6-axis force/torque sensing lets it handle delicate insertions and contact tasks with ease.

Intuitive PolyScope touch interface with drag-and-drop program building

You can teach waypoints by simply hand-guiding the arm—physically moving it to show it what to do.

It shares the full e‑Series safety features, with customizable limits on speed, force, and workspace.

Its low typical power draw keeps running costs down and heat buildup low, even in tight enclosures.

It's part of a unified portfolio, so you can reuse skills, code, and accessories across all models.

Product Description

The UR3e is the tiniest in the e‑Series family, designed specifically for workbench tasks. Its 3 kg payload and 500 mm reach make it ideal for screwdriving, light assembly, testing, and lab work. Plus, at just over ten kilos, you can easily move it between stations. Even though it's compact, it packs the same force sensing, safety features, and programming interface as the bigger models, so your skills and programs transfer seamlessly.

Frequently Asked Questions

The UR3e really shines on benchtop tasks like driving screws, assembling small parts, loading test fixtures, and handling lightweight components where you need precision but not a ton of reach.

Yes. Weighing just over ten kilograms with a small base, it's easy to mount on mobile carts or plates and move it around as your production needs shift.

The UR3e comes with an integrated force/torque sensor, so it can feel contact forces and tackle jobs like press-fitting, polishing, or gently placing parts into fixtures.

Most basic tasks can be taught right on the touchscreen or by guiding the robot by hand along the path you want. Operators can jump in after a quick training session—no coding required.

It's built for collaborative work, but skipping fences depends on a risk assessment factoring in your specific tools, parts, and speeds.

The UR3e plugs into standard AC power and sips energy like a small household appliance during everyday use.