UR20 (e‑Series Architecture Variant)

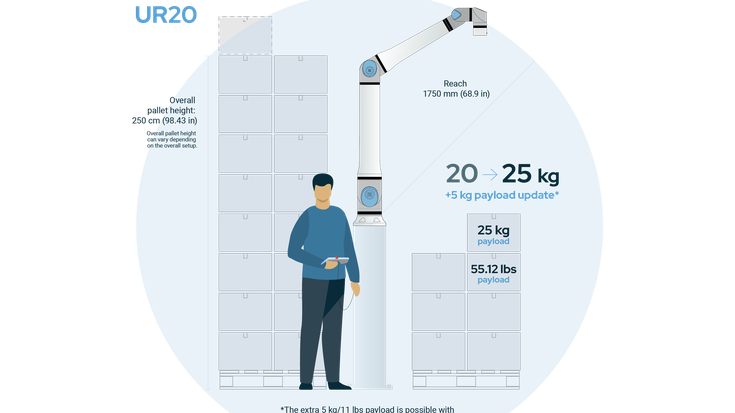

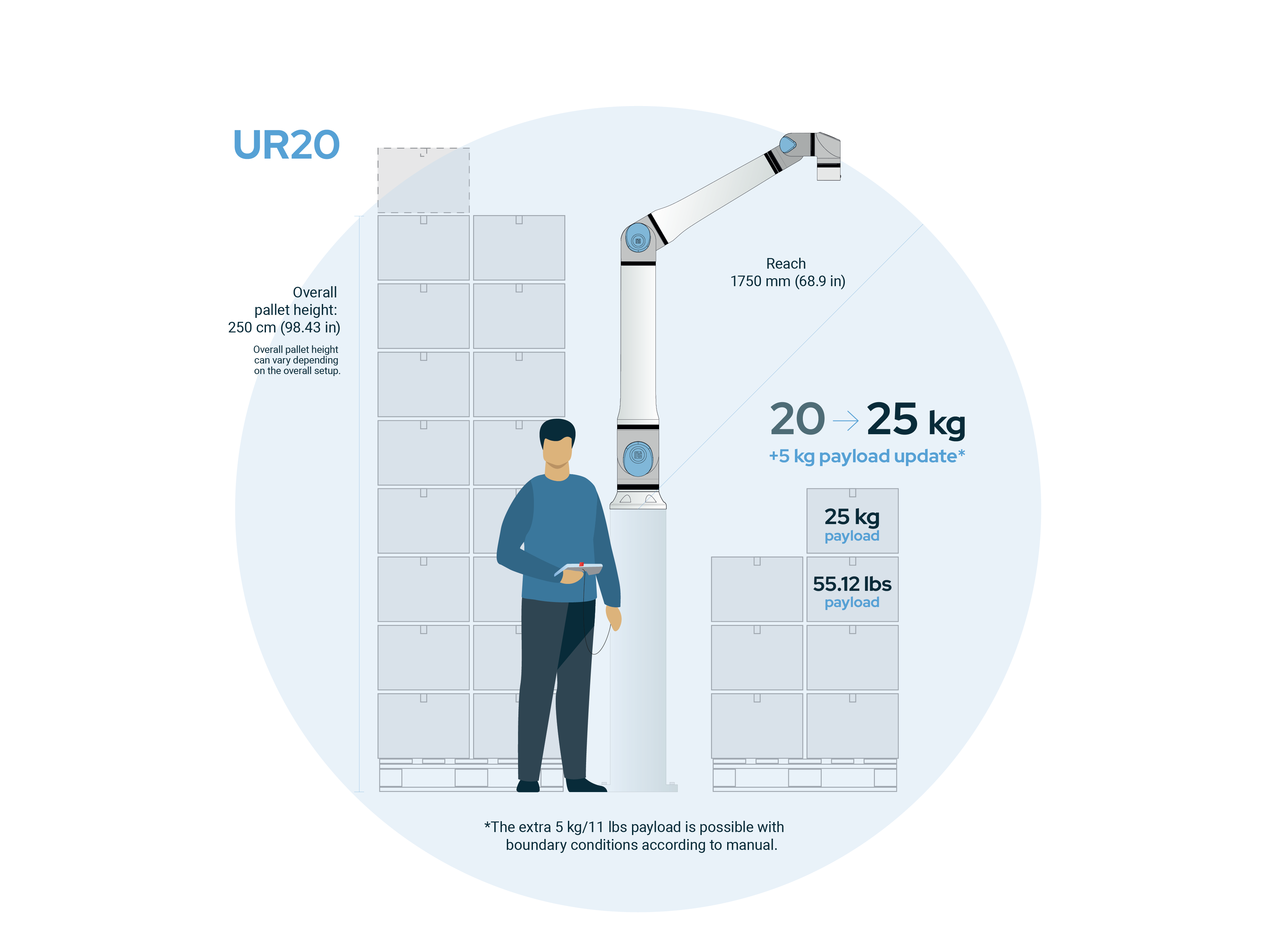

UR20 pushes the e‑Series into bigger cobots for tall palletizing, long-reach tending, and heavy lifting. With 1750 mm reach and payload for big boxes or parts, it covers full pallets from one spot while staying collaborative. It's got fresh mechanics but keeps the familiar e‑Series experience and safety.

Image Gallery

Specifications

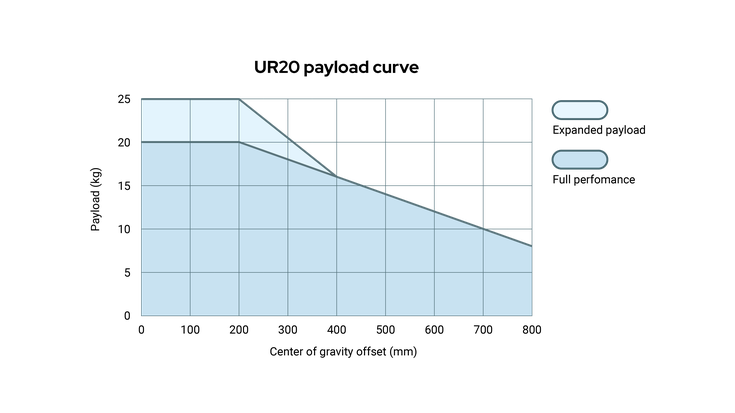

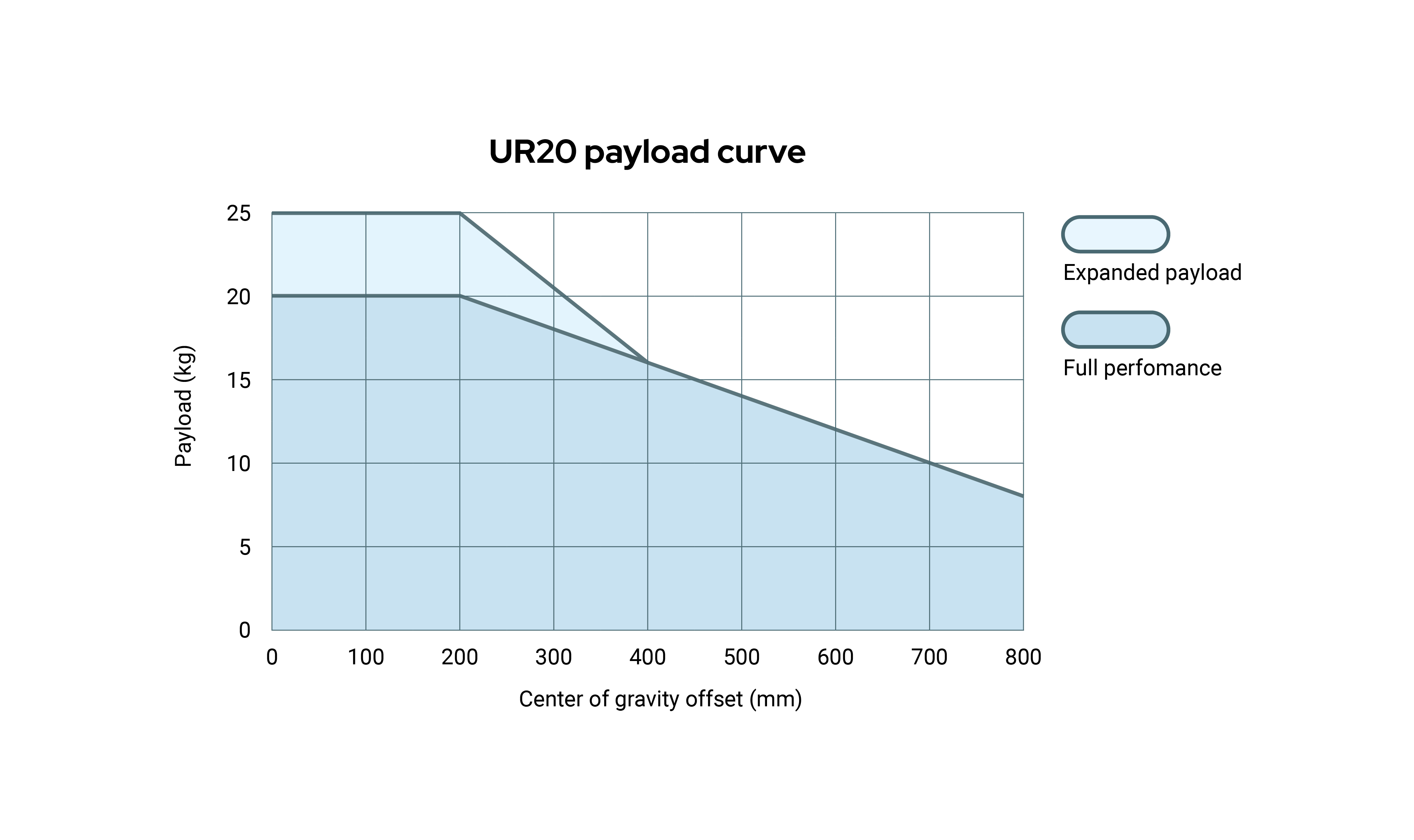

Payload

Up to the 20 kg class in standard e‑Series-style UR20 setups

Reach

1750 mm

Degrees of Freedom

6 rotating joints

Robot Mass

≈ mid‑60 kg range

Repeatability

≈ ± 0.05 mm class

Base Footprint

Compact for its reach, with the same mounting vibe as other UR cobots

Integrated Force Torque Sensor

Present as part of the advanced platform

Power Consumption Max

≈ 750 W (indicative high-load figure)

Power Consumption Typical

≈ 300 W at moderate palletizing speeds

Operating Temperature

0–50 °C

Protection Rating

Industrial IP level suitable for logistics and production environments

Programming Interface

PolyScope with enhanced palletizing and safety tools

Safety Functions

Customizable limits on speed, power, momentum, and space, plus beefed-up diagnostics

Typical Applications

Tall palletizing, end-of-line packaging, long-reach machine tending, large-part handling, logistics automation

Key Features

Impressive 1750 mm reach that easily spans full pallets and wide work areas

Hefty payload perfect for heavy boxes, totes, or medium-sized parts

Fresh arm design with slimmer joints, so it can slip into tight spots even with the extra reach

Powerful joint torques and smart motion planning tailored for palletizing and big handling jobs

Same straightforward programming and safety setup as the rest of the UR lineup

Plays nice with modern palletizing software, like pattern builders and simulators

Built to mount on floors, risers, or bases right next to conveyors or pallet stations

Automates jobs that used to require bulky industrial robots and heavy safety barriers

Powered by the full UR+ ecosystem of grippers, vacuum systems, and vertical axis add-ons

The ideal bridge between traditional heavy industrial robots and agile lightweight cobots

Product Description

The UR20 builds on the e‑Series with a new breed of bigger cobots for stacking tall pallets, long-reach machine tending, and heavy-duty handling. Its 1750 mm reach and robust payload tackle big boxes or parts, covering an entire pallet from one spot while safely sharing space—true to collaborative cobot roots. Even with mechanical upgrades, the user experience and safety features match the e‑Series family perfectly.

Frequently Asked Questions

The UR20 is perfect for tall pallets, expansive work areas, or heavier loads where smaller cobots need multiple setups or extra axes to get the job done.

Yes. Programs, safety setups, and integration tricks carry straight over, so teams with UR experience hit the ground running.

You'll often see UR20 paired with large vacuum grippers, multi-cup end effectors, or sturdy mechanical grippers built for heavy crates and tricky loads.

UR20 keeps the collaborative spirit alive, but its beefier payload and reach call for thorough risk checks and proper safety measures.

Yes, pair it with the right software and vision or barcode systems, and UR20 builds mixed pallets by smartly adjusting picks and places on the fly.

UR20 broadens the tasks you can cobot-ize, all in the familiar programming world, so it's a breeze to add it alongside smaller UR cobots in your facility.