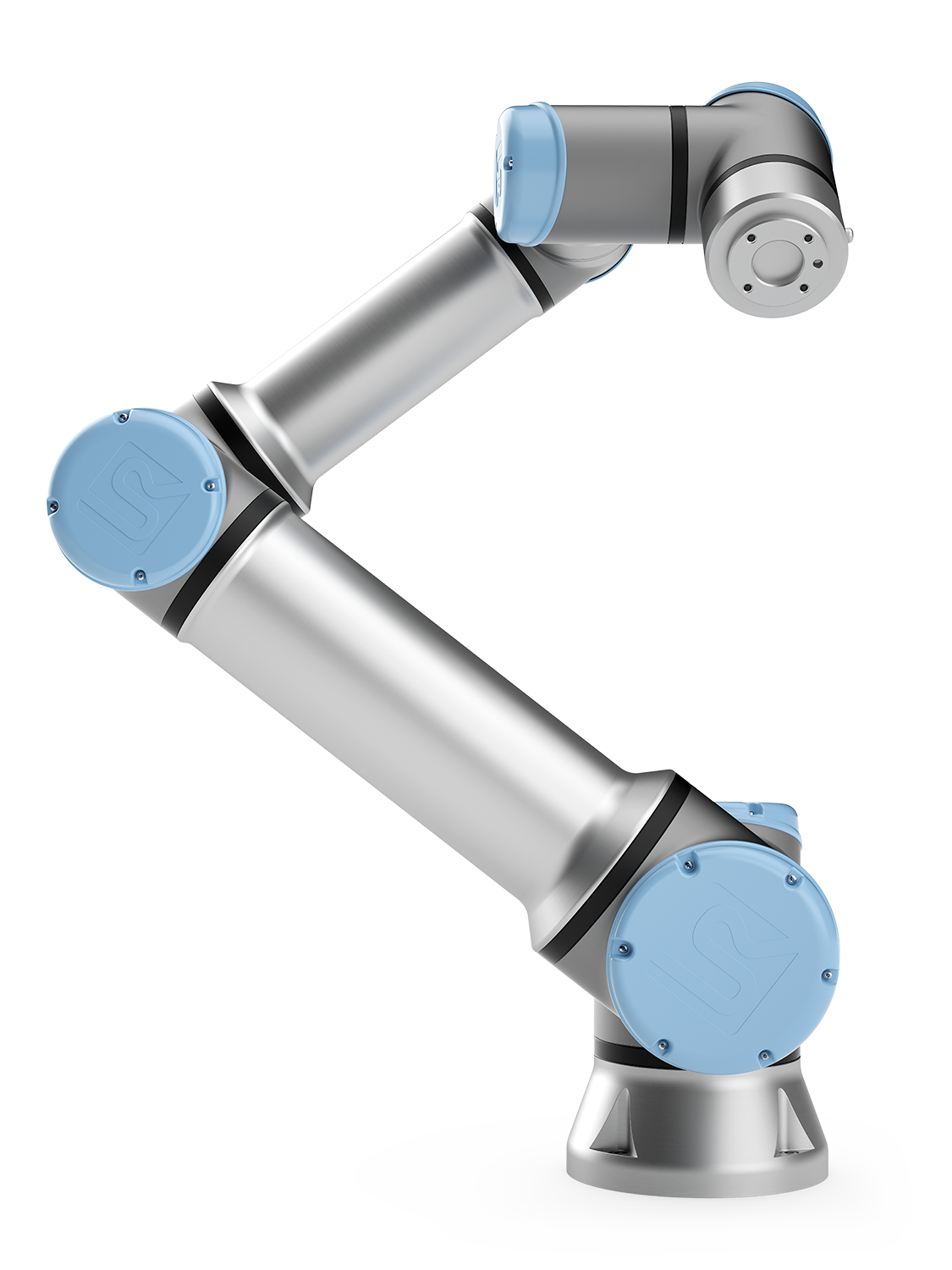

UR16e

UR16e is the powerhouse of the original e‑Series lineup. It packs a 16 kg payload and 900 mm reach into a compact body, perfect for hefting dense parts, grabbing multiple items, or powering high-torque tools. It's the go-to when your machine cell needs extra strength without sacrificing space or collab-friendly vibes.

Image Gallery

Specifications

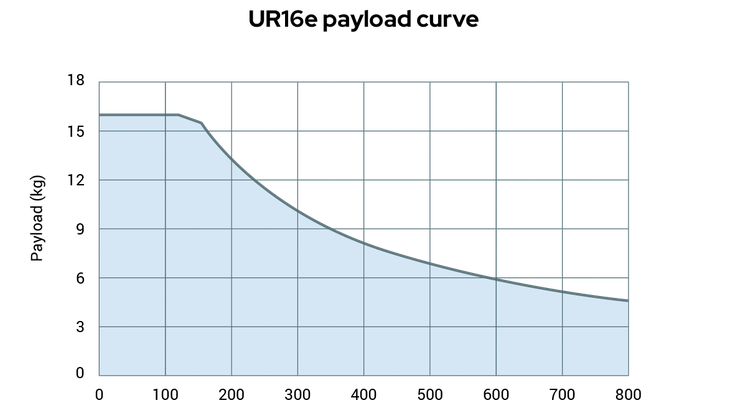

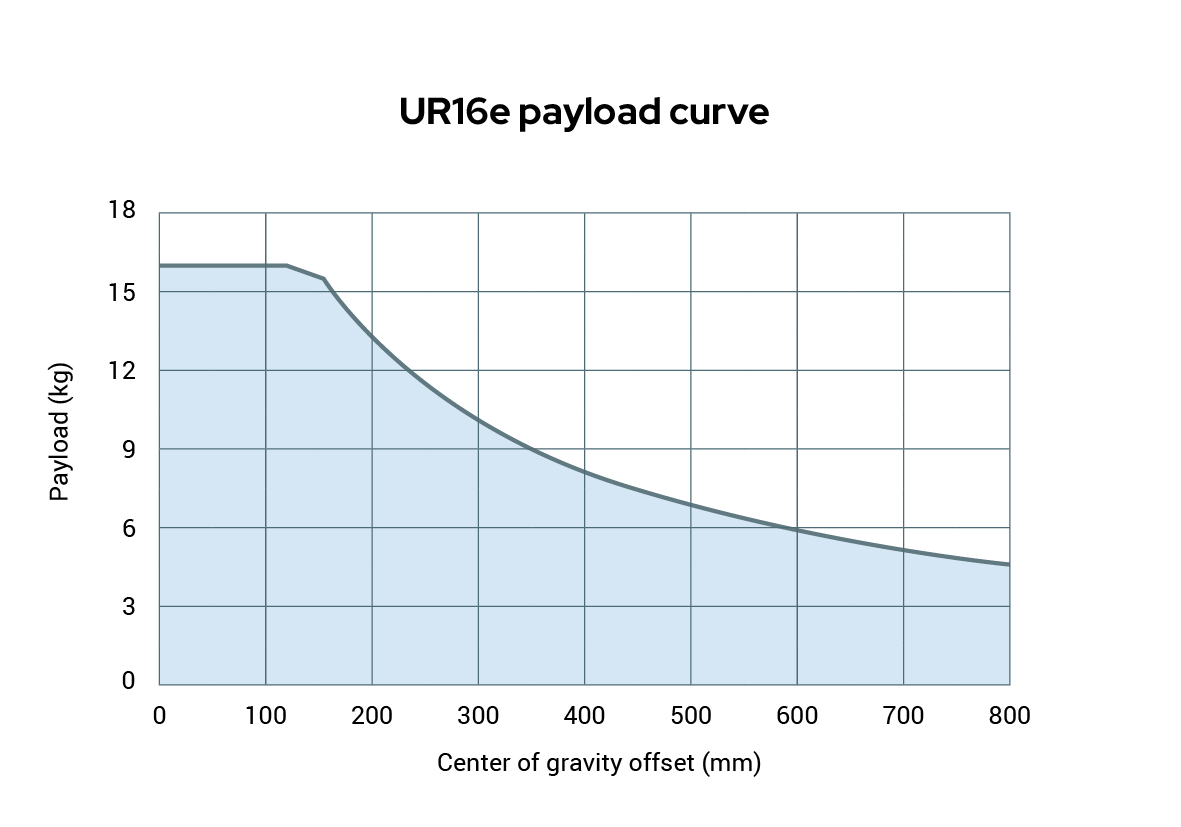

Payload

16 kg

Reach

900 mm

Degrees of Freedom

6 rotating joints

Robot Mass

≈ 33.1 kg

Repeatability

≈ ± 0.05 mm

Base Footprint

≈ Ø 190 mm

Integrated Force Torque Sensor

Yes, 6-axis

Power Consumption Max

≈ 585 W

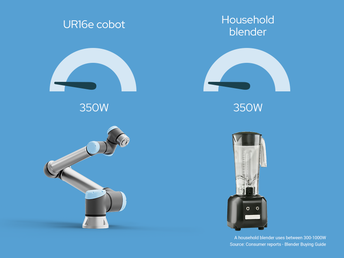

Power Consumption Typical

≈ 350 W

Operating Temperature

0–50 °C

Protection Rating

Industrial IP level for typical machining and handling environments

Programming Interface

PolyScope with support for advanced safety configuration

Safety Functions

Full set of e‑Series safety features including momentum limiting and reduced modes

Typical Applications

Heavy machine tending, handling metal blanks and castings, multi-part picking, high-torque screwdriving, material removal

Key Features

16 kg payload for heavy components, large grippers, or multi-part picking

900 mm reach for handling parts around a machine or within a compact cell

Sturdy joints and higher torque capabilities compared with smaller e‑Series models

You'll love the same intuitive programming and safety features as the rest of the e‑Series family.

Integrated force/torque sensing for controlled contact in heavy applications

It's especially great for loading CNCs, presses, and other gear that handles heavy blanks or castings.

It stays fully collaborative when you keep it within safe speed and force limits.

Super small mounting footprint for its payload—much tinier than traditional industrial robots.

Pairs perfectly with heavy-duty grippers and clamping systems from the UR+ ecosystem.

Built to run non-stop in real-world industrial settings with almost no maintenance.

Product Description

The UR16e is the powerhouse of the original e‑Series lineup. It packs a 16 kg payload and 900 mm reach into a compact design, making it ideal for hoisting dense parts, juggling multiple items, or powering high-torque tools. It's a top pick when your machine cell needs serious strength but still wants a small footprint and collaborative safety.

Frequently Asked Questions

If your parts, fixtures, or tools often push 10–12 kg or more, the UR16e gives you plenty of payload breathing room while keeping things compact.

While it's a natural for machining and metal fab, the UR16e shines in packaging, automotive parts, and anywhere heavy items need frequent moving.

Higher payloads mean more energy in a collision, so you might need slower speeds and extra safeguards to keep things safe around people.

Yep, like other UR cobots, the UR16e handles flexible mounting orientations—as long as your structure can take the loads.

Most UR+ grippers, sensors, and software that match the payload range work seamlessly with the UR16e, making standardization a breeze.

The programming feels identical, so folks used to the UR3e or UR5e can jump onto the UR16e in no time.