KR FORTEC

Discover unbeatable off-road prowess with the KR FORTEC 2.0, a rugged heavy-duty robot with a top IP67 rating. Its advanced multi-link suspension and beefed-up shocks feature a smart anti-collision design, perfect for dominating the toughest terrains.

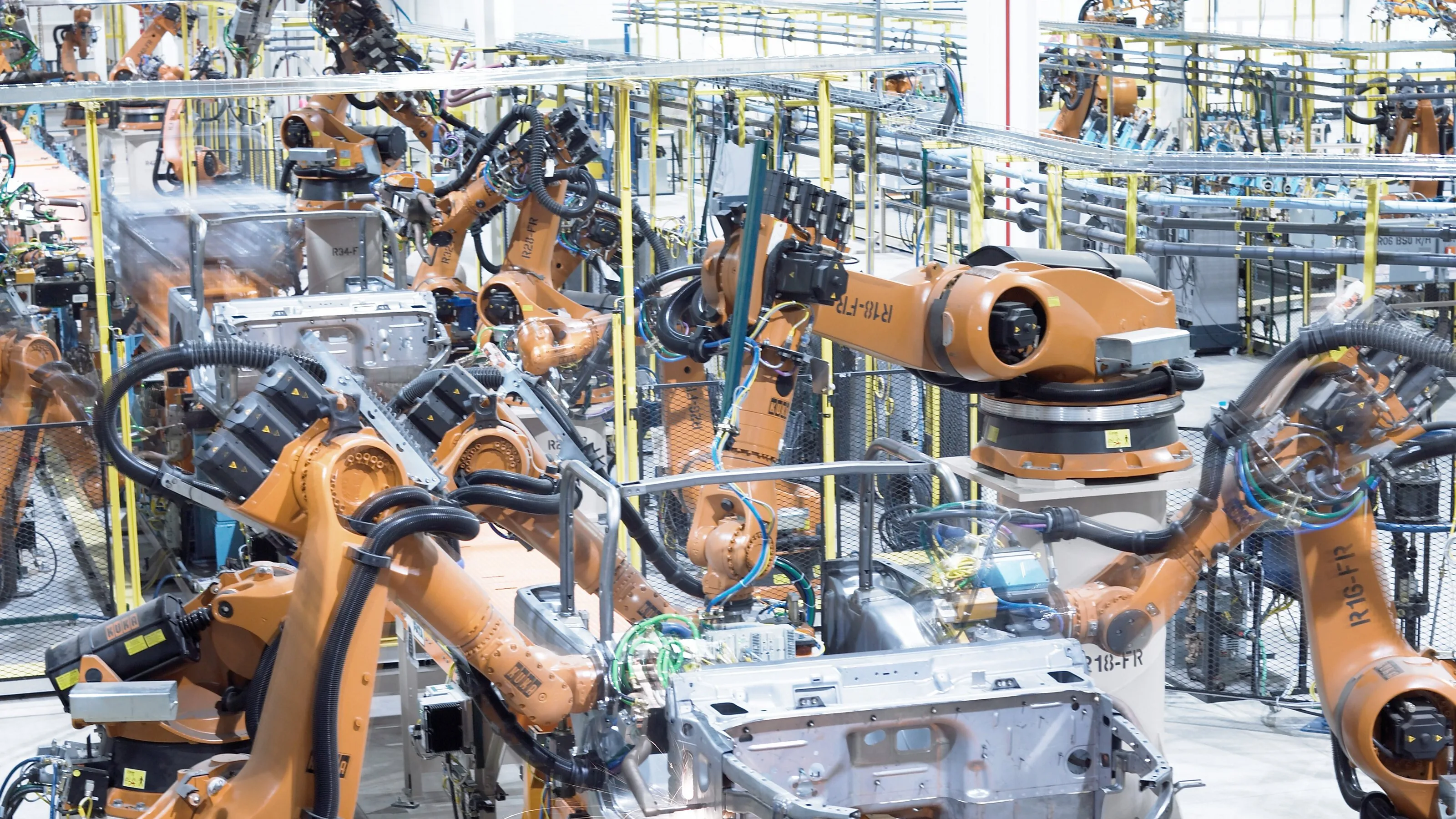

Image Gallery

Specifications

Dimensions

1053mm x 840mm x 508mm

Weight

260kg

Payload

200kg

Max Speed

1.5 m/s

Operating Temperature

-20°C to 60°C

IP Rating

IP67

Climbing Ability

35°

Battery

48V 60Ah

Communication

CAN

Key Features

Seamless Maneuverability

Seamless Maneuverability - The KR FORTEC 2.0 pulls off smooth spot rotations by driving its tracks in opposite directions independently. This makes tight maneuvers in cramped spaces a breeze, ensuring spot-on positioning and agile, controlled moves effortlessly.

Advanced Suspension System

Advanced Suspension System - The KR FORTEC 2.0 shines with incredible flexibility thanks to its low center of gravity. Powered by an 1800W dual-motor drive, it crushes obstacles and climbs like a champ. The independent suspension and heavy-duty shocks deliver a buttery-smooth ride over the roughest ground.

Expansion and Secondary Development

Expansion and Secondary Development - The KR FORTEC 2.0 comes with aluminum T-slot rails for rock-solid mounting of extra sensors or kits. It supports CAN bus for connections and offers open-source SDKs and software to unlock even more potential.

Product Description

Discover unbeatable off-road prowess with the KR FORTEC 2.0, a rugged heavy-duty robot with a top IP67 rating. Its advanced multi-link suspension and beefed-up shocks feature a smart anti-collision design, perfect for dominating the toughest terrains.

Frequently Asked Questions

KR FORTEC handles 360-500 kg payloads, while the ultra version pushes it to 300-800 kg with cutting-edge tech. The ultra brings boosted capabilities, sleeker controls, and better energy efficiency for the next level of heavy lifting.

The Machine Tooling (MT) variant is built for press and die jobs, with a tougher structure, custom wrist, and motion tweaks for quick, precise press tending. It's all about max durability in high-volume press work.

The Mobile/Traveling variant adds a linear track that multiplies the work envelope several times over. One robot can cover huge areas – great for long welds, big sheets, or hitting multiple presses.

Yes, you can add arm extensions up to 500 mm to hit those hard-to-reach spots. They keep the robot's precision and payload intact, all while keeping the base footprint small.

You'll find variants like standard, foundry (tough against heat/dust/water), machine tooling (press-ready), and mobile/traveling (on tracks). Every payload class – 360, 420, 500 kg – comes in these options.

Standard range is 5°C to 45°C. Foundry handles hotter foundry temps, and we've got special cooling for extreme heat.