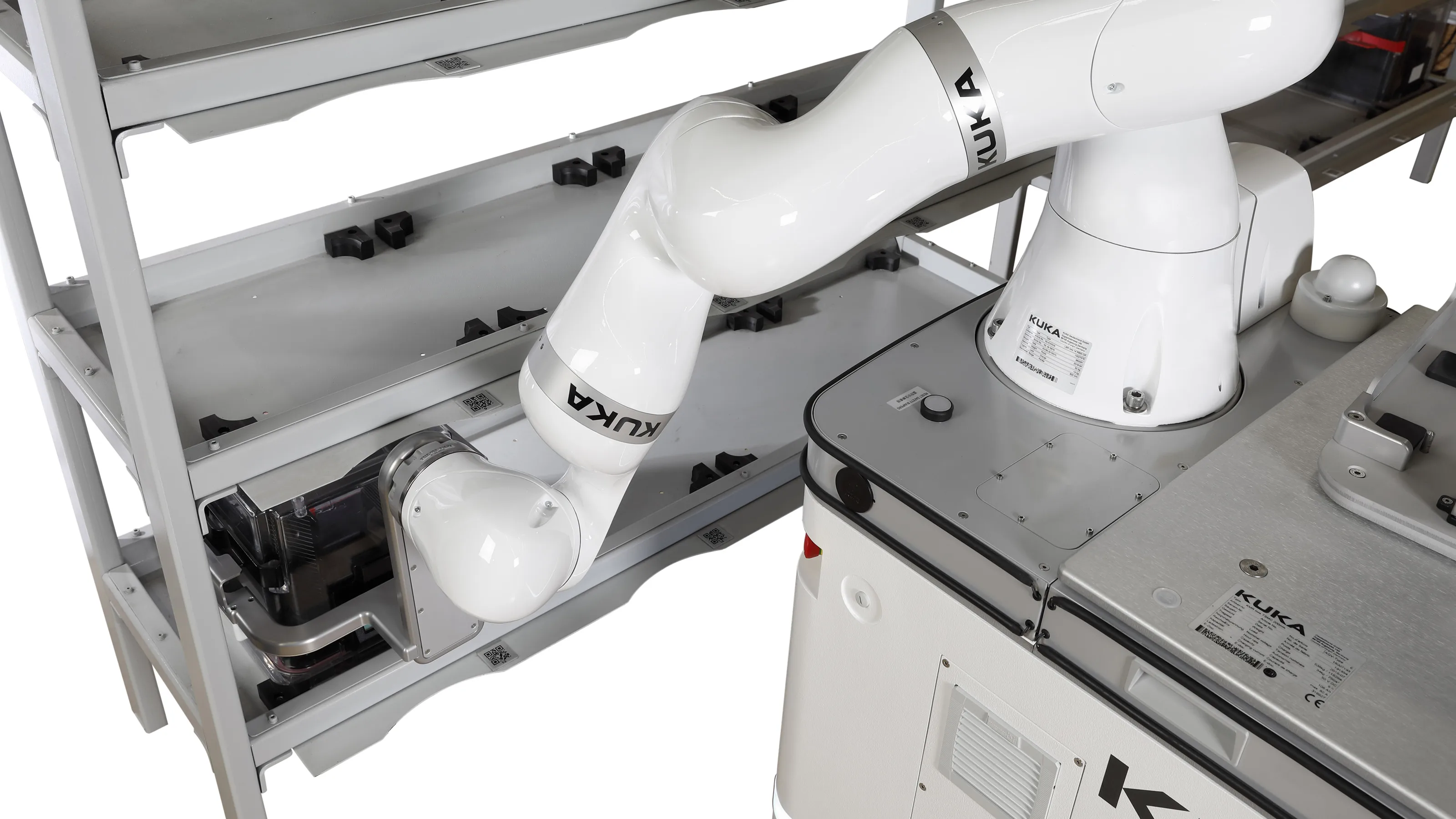

KR C5 Controller

Take on the toughest terrains with unbeatable off-road performance from the KR C5 Controller 2.0, a rugged heavy-duty robot with a top IP67 rating. Its advanced multi-link suspension and beefed-up shocks feature a smart anti-collision design that's perfect for dominating any rough ground.

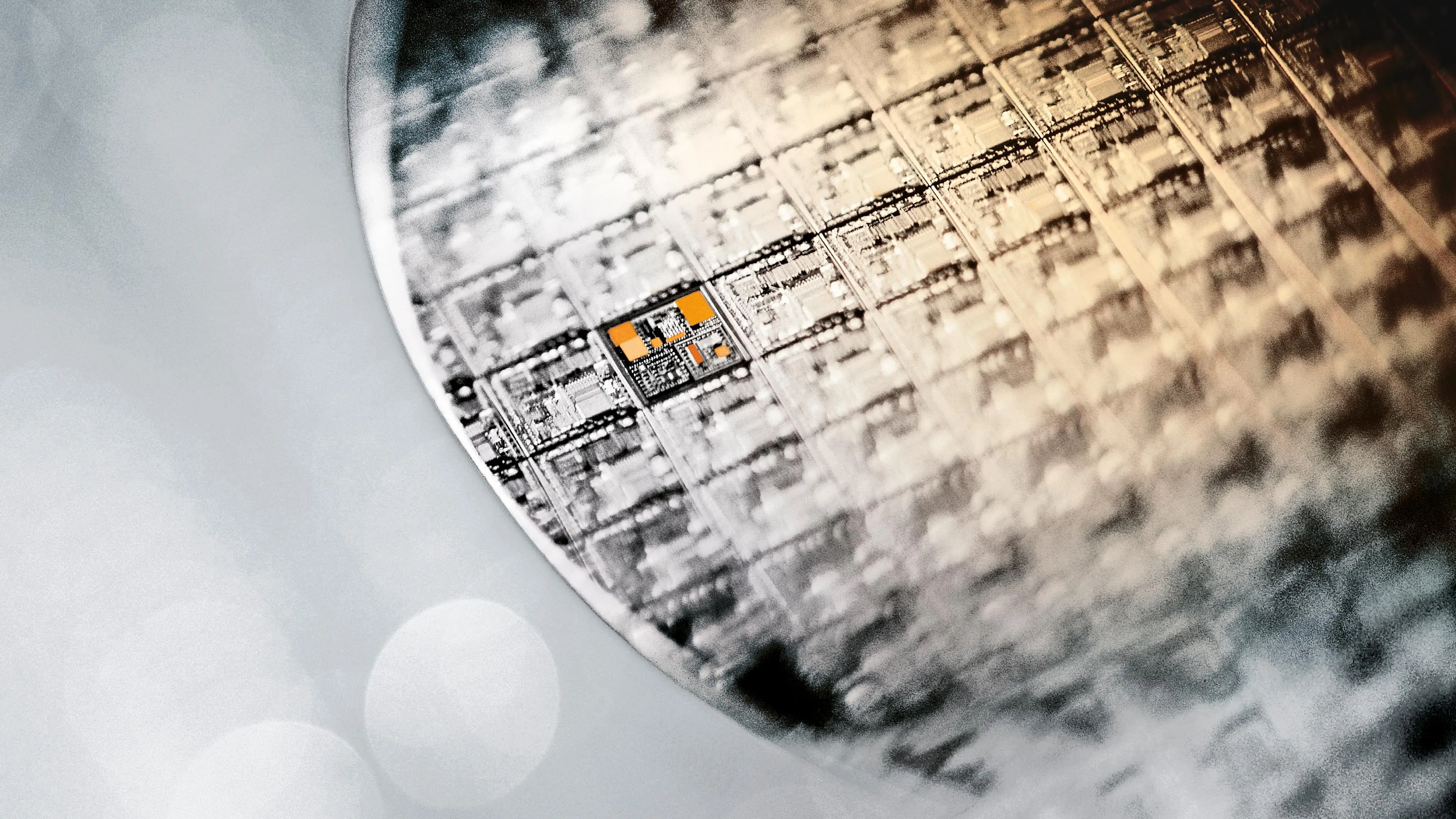

Image Gallery

Specifications

Dimensions

1053mm x 840mm x 508mm

Weight

260kg

Payload

200kg

Max Speed

1.5 m/s

Operating Temperature

-20°C to 60°C

IP Rating

IP67

Climbing Ability

35°

Battery

48V 60Ah

Communication

CAN

Key Features

Seamless Maneuverability

Seamless Maneuverability - The KR C5 Controller 2.0 nails spot rotations effortlessly by driving its tracks in opposite directions independently. This lets it make precise moves in tight spots and hit exact positions every time, for super agile and controlled handling.

Advanced Suspension System

Advanced Suspension System - The KR C5 Controller 2.0 shines with incredible flexibility thanks to its low center of gravity. Powered by a 1800W dual-motor drive, it crushes obstacles and steep climbs like a champ. The independent suspension and heavy-duty shocks keep rides smooth even over the roughest paths.

Expansion and Secondary Development

Expansion and Secondary Development - The KR C5 Controller 2.0 comes with handy aluminum T-slot rails for mounting sensors or add-ons securely. It works with CAN bus for connections and offers open-source SDK and software to unlock even more possibilities.

Product Description

Take on the toughest terrains with unbeatable off-road performance from the KR C5 Controller 2.0, a rugged heavy-duty robot with a top IP67 rating. Its advanced multi-link suspension and beefed-up shocks feature a smart anti-collision design that's perfect for dominating any rough ground.

Frequently Asked Questions

At just 16 liters and 9 kg, the KR C5 micro fits robot setups into the tightest spaces – mount it on a wall, shelf, or rack. It runs on standard single-phase 220V power with the latest KUKA System Software 8.7, making it perfect for small shops or easy retrofits.

A standard KR C5 cabinet handles up to 8 servo axes. That could be one big multi-axis robot, several smaller ones, or bots with extra axes. For bigger multi-robot setups, just network multiple cabinets together.

The KR C5 with KUKA System Software 8.7+ plays nice with KR C4 programs, so you can upgrade old systems without rewriting everything. Some older bots might need adapter modules, though.

The KR C5 packs safety features like emergency stops, safe motion control, force limiting for collab work, and standstill monitoring – all certified to ISO 13849-1 for critical safety needs.

The KR C5 brings Gigabit Ethernet, built-in network security, and support for key protocols like ProfiNET, DeviceNet, and EtherCAT. This makes hooking it up to MES, ERP, or IoT systems a breeze for full production insights.

Absolutely – the KR C5 micro has optional brackets for standard 19-inch rack rails, so it slots right into data centers or control rooms. You can even stack multiples in one cabinet.