BUNKER PRO

The DENSO VS Series is our go-to family of compact 6-axis robots, covering 4-7 kg payloads and 505-905 mm reaches. We've got variants for every need, including the VS-050S2 pharma robot that's certified for brutal sterilization. It delivers top-tier precision (±0.02 mm repeatability) and rock-solid reliability. Choose from standard models, dust/mist-proof IP65 or cleanroom versions, and H2O2-resistant pharma specials. Internal cabling, tiny footprint, and a two-year warranty make it ideal for assembly, handling, inspection, and pharma work.

Image Gallery

Specifications

Payload Variants

4 kg (VS-050/060), 7 kg (VS-068/087/6556/6577)

Reach Options

505-905 mm depending on model

Number of Axes

6

Position Repeatability

±0.02 mm (standard models), ±0.02 mm (pharmaceutical)

IP Protection

IP54 (standard), IP65 (dust/mistproof), IP67 optional

Environmental Certification

Standard, Dust/mistproof, Cleanroom, Pharmaceutical (VS-050S2)

Pharmaceutical Features

H2O2 gas (35% density) resistant, UV sterilization compatible, FDA material certification

Cleanliness

ISO Class 5 (pharmaceutical models)

GMP Compliance

Grade A for pharmaceutical models

Operating Temperature

0°C to +45°C

Robot Weight

15-35 kg depending on variant

Key Models

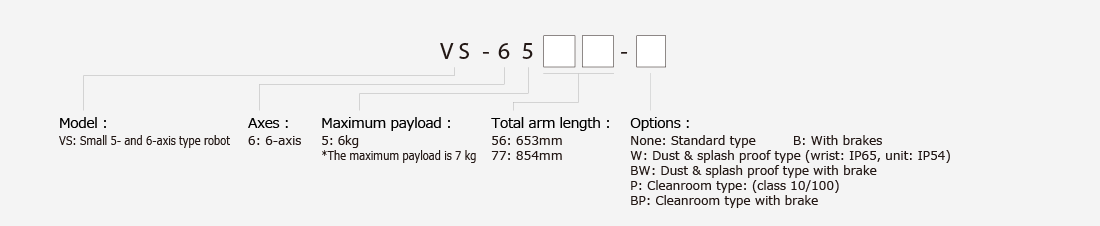

VS-050, VS-060, VS-068, VS-087, VS-6556, VS-6577, VS-050S2

Controller Compatible

RC8A

Applications

Assembly, Material handling, Inspection, Pharmaceutical/medical automation, Cleanroom operations

Weight

260kg

Payload

200kg

Max Speed

1.5 m/s

Operating Temperature

-20°C to 60°C

IP Rating

IP67

Climbing Ability

35°

Battery

48V 60Ah

Communication

CAN

Key Features

Comprehensive payload range (4

7 kg) with multiple reach options (505-905 mm)

Feature

Exceptional precision with ±0.02 mm position repeatability

Feature

Compact design reducing facility footprint while maintaining full capability

Feature

Multiple environmental variants: standard, dust/mistproof (IP65), cleanroom, pharmaceutical

VS

050S2 pharmaceutical variant with H2O2 sterilization resistance

Feature

ISO Class 5 cleanroom certification for pharmaceutical and medical applications

Feature

GMP Grade A compliance for pharmaceutical manufacturing

Feature

Internally routed cables eliminating external cable management

High

speed operation for rapid assembly cycles

Two

year warranty with minimal maintenance requirements

Advanced Suspension System

Advanced Suspension System - BUNKER PRO 2.0 gives you unbeatable flexibility thanks to its low center of gravity. Powered by a 1800W dual-motor drive, it conquers obstacles and climbs like a champ. The independent suspension and heavy-duty shocks deliver a buttery-smooth ride, even over the roughest terrain.

Expansion and Secondary Development

Expansion and Secondary Development - BUNKER PRO 2.0 comes with aluminum T-slot rails for rock-solid mounting of sensors or add-ons. It supports CAN bus for easy connections and offers open-source SDKs and software to unlock even more possibilities.

Product Description

The DENSO VS Series is our go-to family of compact 6-axis robots, covering 4-7 kg payloads and 505-905 mm reaches. We've got variants for every need, including the VS-050S2 pharma robot that's certified for brutal sterilization. It delivers top-tier precision (±0.02 mm repeatability) and rock-solid reliability. Choose from standard models, dust/mist-proof IP65 or cleanroom versions, and H2O2-resistant pharma specials. Internal cabling, tiny footprint, and a two-year warranty make it ideal for assembly, handling, inspection, and pharma work.

Frequently Asked Questions

The VS-050S2 stands up to H2O2 gas (35% density) and UV sterilization, boasts ISO Class 5 cleanroom cert, GMP Grade A compliance, FDA-approved materials, sealed connectors, and internal cabling. It's built to ace the toughest pharma and med device manufacturing demands.

The IP65 version features sealed connectors, protective covers, and airtight seals at every joint and cable entry. It shields against dust, moisture, and mist in real-world manufacturing without slowing down performance.

Yes, the VS Series is made for non-stop high-speed runs with little upkeep. Beefy servos, premium bearings, and sealed parts handle long shifts in demanding factories.

Expect 0.35-0.40 second cycle times depending on the model and task. Even the VS-050S2 pharma robot nails 0.35 seconds, seals and all.

Cleanroom options exist for standard VS models, while the VS-050S2 is pharma cleanroom-ready. Chat with DENSO for certs on your specific model.

Our two-year warranty covers defects in materials and build quality for normal use with routine maintenance. Extended plans are available for heavy-duty setups.