BUNKER PRO

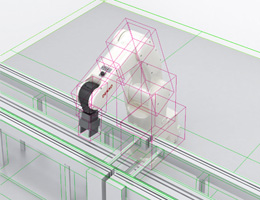

The RC8A is DENSO's world-leading compact, high-performance 8-axis robot controller engineered for universal compatibility across all DENSO robot models. As the smallest high-performance robot controller in its class, the RC8A delivers advanced motion control, multiple I/O options, and flexible installation capability. Supporting up to 8 axes with simultaneous multi-robot control, the RC8A combines powerful processing with intuitive programming through WINCAPS software. The RC8A's unified controller approach enables seamless integration of any combination of DENSO robots (VP, VS, VM, SCARA, COBOTTA) on a single control platform, reducing system complexity and maintenance costs while maximizing flexibility.

Image Gallery

Specifications

Maximum Axes

8

Compatible Robot Models

All DENSO robots (VP, VS, VM, VMB, VLA, HS-A1, HSR, HM, LPH, COBOTTA, COBOTTA PRO)

Physical Form Factor

Compact desktop or rack-mount configuration

Weight

~10 kg

Power Supply

Single or three-phase AC input

Power Consumption

Compact and efficient design

I/O Options

Analog inputs, analog outputs, digital inputs, digital outputs

Fieldbus Support

Ethernet, RS-485, and other industrial protocols

Display

Color touchscreen programming pendant

Programming Software

WINCAPS, WINCAPS Plus (3D visual)

Operating Temperature

0°C to +50°C

IP Protection

IP54 (standard)

Memory

Adequate for complex multi-robot programs

Communication Interfaces

USB, Ethernet for integration with other systems

Weight

260kg

Payload

200kg

Max Speed

1.5 m/s

Operating Temperature

-20°C to 60°C

IP Rating

IP67

Climbing Ability

35°

Battery

48V 60Ah

Communication

CAN

Key Features

World's smallest high

performance 8-axis robot controller with space-saving design

Compact, lightweight construction enabling flexible installation (wall

mount, shelf-mount, rack-mount)

Universal compatibility with all DENSO robot models (VP, VS, VM, HS

A1, HSR, HM, COBOTTA, LPH)

Feature

Support for up to 8 axes enabling control of multiple robots or extended axis configurations

Feature

Advanced servo motion control algorithms optimizing performance for each robot type

Multiple I/O options: analog inputs/outputs, digital I/O, fieldbus networks (Ethernet, RS

485, etc.)

Feature

WINCAPS Plus 3D visual programming interface enabling intuitive program development

Feature

Unified programming environment reducing learning curve and accelerating deployment

Energy

efficient operation reducing power consumption and heat generation

Feature

Modular design supporting future expansion with additional axes and interfaces

Advanced Suspension System

Advanced Suspension System - BUNKER PRO 2.0 delivers unbeatable flexibility thanks to its low center of gravity. Powered by an 1800W dual-motor drive, it crushes obstacles and climbs with ease. The independent suspension and heavy-duty shock absorbers ensure a smooth ride over the roughest terrain.

Expansion and Secondary Development

Expansion and Secondary Development - BUNKER PRO 2.0 makes it easy to add on with aluminum T-slot rails for securely mounting external sensors or kits. It supports CAN bus protocol for connections and includes open-source SDK and software resources to unlock even more capabilities.

Product Description

The RC8A is DENSO's world-leading compact, high-performance 8-axis robot controller engineered for universal compatibility across all DENSO robot models. As the smallest high-performance robot controller in its class, the RC8A delivers advanced motion control, multiple I/O options, and flexible installation capability. Supporting up to 8 axes with simultaneous multi-robot control, the RC8A combines powerful processing with intuitive programming through WINCAPS software. The RC8A's unified controller approach enables seamless integration of any combination of DENSO robots (VP, VS, VM, SCARA, COBOTTA) on a single control platform, reducing system complexity and maintenance costs while maximizing flexibility.

Frequently Asked Questions

The RC8A supports up to 8 axes total. This could be one 6-axis robot plus one 2-axis external axis, or multiple smaller SCARA robots, or coordinated multi-robot systems. Configuration depends on specific application requirements.

The RC8A provides backward compatibility with older controller programs. Program migration may be required for optimal performance, and Denso provides tools and support for legacy program conversion.

One RC8A controller can handle multiple DENSO robots, simplifying your setup by cutting system complexity, easing the programming learning curve, reducing training needs, shrinking spare parts inventory, and lowering maintenance costs—all while letting you run coordinated multi-robot operations smoothly.

WINCAPS Plus makes it super easy to build 3D visual robot programs without diving into heavy text coding. Operators get to see robot movements in action, simulate potential collisions, and tweak programs using a straightforward graphical interface instead of wrestling with complex code.

The RC8A plays nice with standard industrial fieldbuses like Ethernet, RS-485, and more depending on your module setup. This lets you seamlessly integrate it into your facility's automation systems for real-time control.

Yes, the RC8A is built for tough industrial manufacturing with solid IP54 protection and rugged electronics. For really extreme conditions—like heavy dust, moisture, or wild temperatures—we recommend adding specialized enclosures or extra environmental shielding.