Inventory Management & Stocktaking

Supercharge warehouse accuracy with mobile robots handling cycle counts and inventory checks. Eliminate human errors, get live stock views, and run 24/7 without disrupting workflows.

Why Automate Inventory Management & Stocktaking?

99.9% Data Accuracy

Say goodbye to counting mistakes. RFID and barcode scans deliver precise data straight to your ERP.

Continuous Cycle Counting

Ditch yearly audits—check stock nightly or between shifts for round-the-clock visibility.

Reduced Labor Costs

Shift staff from counting to fulfillment for better efficiency.

Scalable Integration

Plugs seamlessly into WMS like SAP, Oracle, Dynamics via REST APIs.

High-Rack Reach

Telescopic masts or drones scan high shelves—no lifts required.

Enhanced Safety

Reduce aisle foot traffic and cut height-related risks from manual counts.

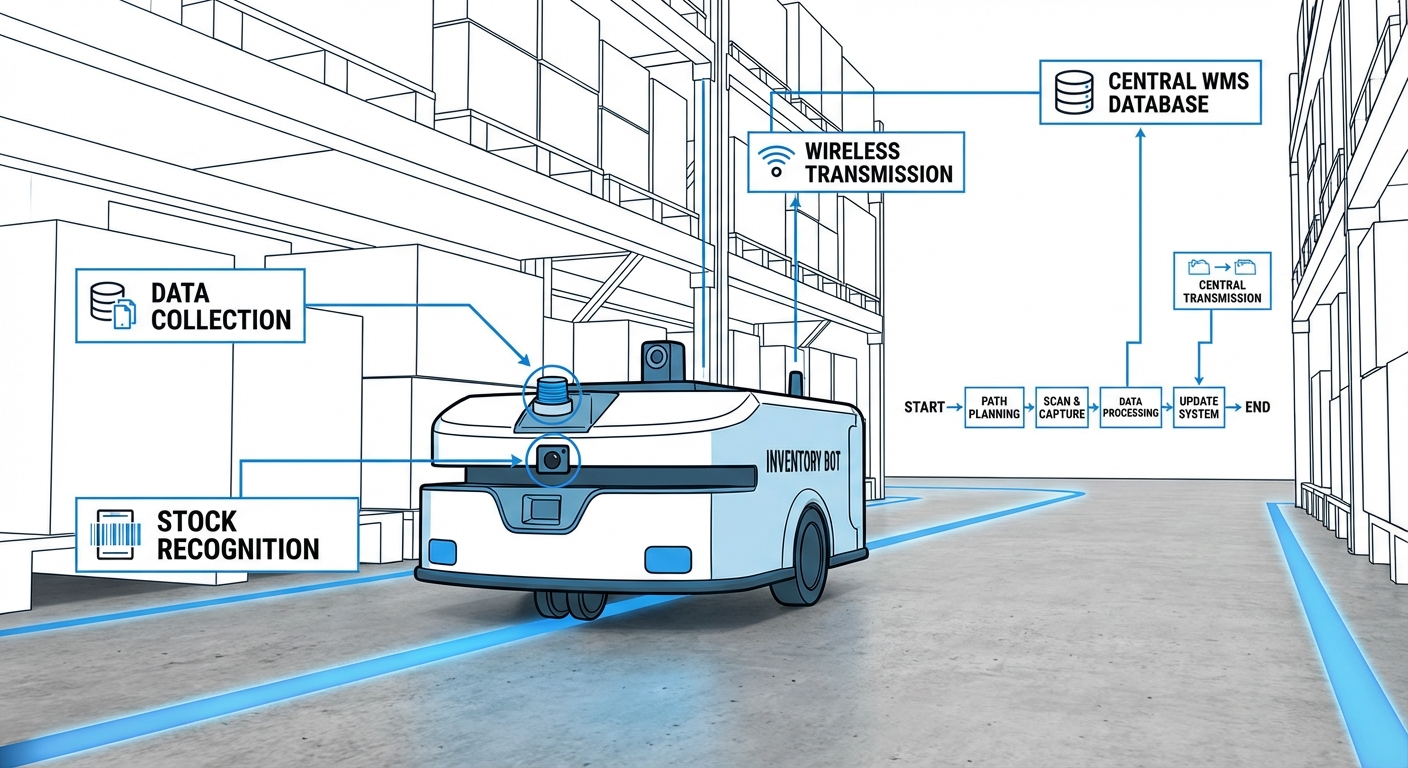

Autonomous Workflow Integration

Stocktaking kicks off with a mission map. SLAM navigates the robot through aisles, dodging obstacles along the way.

At the racks, RGB-D cameras, barcodes, and RFID capture SKU, batch, and quantity data—processed right on the edge.

Mismatches get flagged immediately. Sync real-time or in batches to your WMS for instant issue reports.

Where It's Used

3PL & Logistics Centers

Key for fast-turnover spots—matches physical to digital pre-shift.

Retail Fulfillment

Omnichannel stores use them to prevent stockouts, keeping online inventory perfectly synced with the warehouse.

Manufacturing

Raw materials: confirm parts for lines, avoid stoppages.

Pharmaceutical Warehousing

Tracks expirations and batches (FEFO) for compliance.

What You Need

| Category | Requirements |

|---|---|

| Sensors | 2D/3D LiDAR for navigation; RGB cameras for visual tags; UHF RFID readers. |

| Robot Capabilities | AMR base with SLAM navigation; telescoping mast for vertical reach (up to 12m). |

| Infrastructure | Standardized rack labeling (QR/Barcode) or RFID tags on pallets/items; flat flooring. |

| Software Stack | Fleet Management System; WMS Integration Middleware (REST API/SOAP). |

| Connectivity | Industrial Wi-Fi 6 or Private 5G network for real-time video/data transmission. |