VM Series (Mid-Size 6-Axis)

The DENSO VM Series represents the next step in payload capacity while maintaining compact design philosophy. With 13 kg payload and reaches of 1021-1298 mm, the VM Series bridges the gap between compact VS robots and high-payload VMB/VLA systems. Delivering professional-grade precision (±0.03 mm repeatability), exceptional speed, and robust construction, the VM Series excels in material handling, machine tending, assembly of larger components, and general industrial automation. The space-saving design enables flexible cell layouts while the internal cable routing and proven reliability make VM Series an ideal choice for manufacturing facilities requiring mid-range payload capability with high-precision performance.

Specifications

Payload

13 kg

Reach

1021-1298 mm

Number of Axes

6

Position Repeatability

±0.03 mm

Key Models

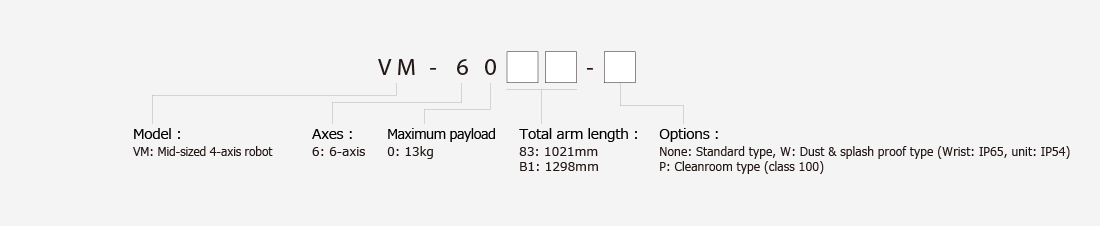

VM-6083 (1021 mm reach), VM-60B1 (1298 mm reach)

Robot Weight

25-35 kg

Operating Temperature

0°C to +45°C

IP Protection

IP54 (standard), IP65 optional

Power Consumption

Moderate (1-2 kVA typical)

Mounting Options

Floor, wall, ceiling flexible installation

Controller Compatible

RC8A

Applications

Material handling, Machine tending, Medium-sized component assembly, General industrial automation, Palletizing light payloads

Key Features

Generous 13 kg payload enabling handling of medium

sized components

Extended reach of 1021

1298 mm covering larger work envelopes

Precision of ±0.03 mm maintaining tight

tolerance positioning

Compact design despite mid

range payload enabling space-efficient installation

Feature

Internally routed cables and air lines preventing external interference

High

speed operation enabling rapid material handling cycles

Feature

Robust servo construction for continuous industrial operation

Multiple environmental variants available (standard, cleanroom, dust

proof)

Feature

Compatible with unified RC8A controller

Minimal maintenance requirements with two

year warranty

Product Description

The DENSO VM Series represents the next step in payload capacity while maintaining compact design philosophy. With 13 kg payload and reaches of 1021-1298 mm, the VM Series bridges the gap between compact VS robots and high-payload VMB/VLA systems. Delivering professional-grade precision (±0.03 mm repeatability), exceptional speed, and robust construction, the VM Series excels in material handling, machine tending, assembly of larger components, and general industrial automation. The space-saving design enables flexible cell layouts while the internal cable routing and proven reliability make VM Series an ideal choice for manufacturing facilities requiring mid-range payload capability with high-precision performance.

Frequently Asked Questions

The VM Series offers 13 kg payload (vs 4-7 kg for VS) and longer reach (1021-1298 mm vs 505-905 mm), making it ideal for handling larger, heavier components while maintaining Denso's precision standards (±0.03 mm).

Yes, the 13 kg payload and extended reach make the VM Series excellent for machine tending applications including loading/unloading, part transfers between machines, and general material handling in manufacturing.

Typical cycle times vary by application but range from 0.8-1.5 seconds depending on the distance traveled and component weight. The high-speed servo motors enable rapid repositioning.

Yes, for light-duty palletizing applications with 13 kg maximum per unit load. The extended reach and payload make it suitable for building pallets with smaller components or lightweight items.

The VM Series is available in standard IP54 configuration. Dust-proof (IP65) and other environmental variants may be available upon request for specific manufacturing environments.

Yes, the VM Series has a standard wrist flange compatible with common end-effectors including grippers, vacuum systems, and custom tools. Internal air and electrical routing supports integrated tooling.