ABB Robotics

Explore our range of intelligent robots and autonomous platforms from ABB Robotics.

All Products

IRB 1010

The IRB 1010 is ABB's smallest industrial robot, engineered for high-precision applications in extremely compact spaces. With a payload of just 1.5 kg and a reach of 370 mm, it delivers class-leading repeatability of 0.01 mm. Designed for miniaturized electronics, wearable devices, and precision assembly where space constraints are critical. The IRB 1010 integrates with OmniCore E10 controller for 20% lower energy consumption and simple programming through Robot Control Mate.

IRB 1100

The IRB 1100 is a class-leading compact robot delivering up to 35% faster cycle times and best-in-class repeatability for high-quality manufacturing. Available with payload options from 4 to 10 kg and reach up to 580 mm, the IRB 1100 offers the highest payload for a robot of its class while featuring a 10% smaller footprint and 20% weight reduction compared to previous generation. Powered by OmniCore, it's optimized for assembly, pick-and-place, and material handling in confined spaces.

IRB 1200 Next Generation

The IRB 1200 Next Generation is an ultra-high-performance compact industrial robot designed for electronics assembly and precision manufacturing. Available in four payload variants (5, 7, 8, 9 kg) with reach of 0.7-0.9 m, this robot delivers class-leading repeatability of 0.03 mm. The new generation is 20% lighter, reducing mounting costs and energy consumption. With max speed of 1600 mm/s and OmniCore support, it's optimized for high-speed, high-precision assembly, FPC placement, and surface finishing in dense production environments.

IRB 1300

The IRB 1300 is a versatile compact robot designed for medium-payload applications requiring reliable performance in diverse manufacturing environments. With a payload of 10 kg and reach of 1.15 m, the IRB 1300 bridges the gap between ultra-compact and medium-sized robots. It delivers excellent repeatability and is suitable for material handling, assembly, and machine tending in confined spaces where a larger footprint cannot be accommodated.

IRB 1600

The IRB 1600 is the highest performance 10 kg robot in its class, engineered to deliver exceptional speed without compromising accuracy. Available in multiple variants with reaches up to 1.45 m, the IRB 1600 features cycle times up to 50% shorter than competing robots. Built for reliability in tough production environments with IP54 standard and optional Foundry Plus IP67 protection. Its flexible mounting and compact design make it ideal for material handling, machine tending, and process applications in dense manufacturing cells.

IRB 2600

The IRB 2600 is a compact high-payload robot optimized for arc welding, material handling, and machine tending. Part of the Sharp generation range with enhanced capabilities in a smaller footprint, the IRB 2600 offers payloads up to 20 kg with reach up to 1.85 m. It features best-in-class accuracy through TrueMove motion control, compact design reducing floorspace requirements, and comprehensive IP protection including optional Foundry Plus 2 package for harsh environments.

IRB 4600

The IRB 4600 is a versatile mid-range general purpose robot offering payloads from 20 to 60 kg with reaches up to 2.55 m. Designed for material handling, machine tending, assembly, and process applications, the IRB 4600 bridges the gap between compact and heavy-duty robots. Its flexible configuration options, proven reliability, and comprehensive protection packages make it suitable for diverse manufacturing environments from clean rooms to foundries.

IRB 5720

The IRB 5720 expands ABB's large-robot portfolio with high performance and advanced capabilities. Available in four variants with payloads from 90 to 180 kg and reaches from 2.6 to 3.0 m, the IRB 5720 is ideal for material handling, machine tending, and high-precision assembly applications. Optimized for Electric Vehicle battery production, automotive, and general manufacturing, the IRB 5720 combines power, precision, and energy efficiency for demanding industrial applications.

IRB 6710

The IRB 6710 is part of ABB's next-generation large robot family delivering exceptional performance with up to 20% energy savings. Available in multiple variants with payloads from 150 to 210 kg and reaches from 2.65 to 2.95 m, the IRB 6710 offers class-leading position repeatability of 0.03 mm. Powered by OmniCore controller, this modular robot features standardized components across the large robot platform, 11 variants with LeanID DressPack option, and comprehensive protection for harsh environments.

IRB 6700

The IRB 6700 represents 40 years of ABB's robotics expertise in large industrial robots. Available in multiple variants with payloads from 150 to 300 kg and reaches from 2.6 to 3.2 m, the IRB 6700 combines robust design, longer service intervals, and increased efficiency resulting in 20% reduction in total cost of ownership. With optional Foundry Plus 2 protection, comprehensive safety features, and LeanID DressPack integration, the IRB 6700 is the benchmark for heavy-duty manufacturing across automotive, foundry, and general industries.

IRB 6750S

The IRB 6750S is a revolutionary shelf-mounted large robot designed to maximize production density through elevated installation. With payloads up to 350 kg and reach up to 3.9 m, the IRB 6750S offers 20% energy savings and class-leading motion control. The robot can be installed at height or on a second floor, optimizing space through full vertical and horizontal motion with increased downward reach. Ideal for die casting, injection molding, spot welding, and heavy assembly operations where space optimization is critical.

IRB 6760

The IRB 6760 is ABB's latest press-tending robot specifically engineered for press operations with reinforced axis 1 and 6 delivering 25% longer lifetime and 7% better cycle times. With payloads up to 200 kg, reach up to 3.5 m, and capability to achieve up to 15 strokes per minute (900 parts per hour), the IRB 6760 brings maximum productivity and reliability to press tending. The robot is designed for automotive, electronics, and general manufacturing press shops seeking the highest productivity in press automation.

IRB 7710

The IRB 7710 and IRB 7720 represent ABB's latest generation of extra-large robots with heightened focus on efficient modular design and up to 30% energy savings. The IRB 7710 handles payloads up to 500 kg with reach up to 3.5 m, offering 16 variants with payloads from 280 to 500 kg. Delivering world-class performance and quality while emphasizing energy efficiency and reliability, the IRB 7710 is ideal for heavy material handling, die casting, and welding in automotive, foundry, and general manufacturing.

IRB 7720

The IRB 7720 is ABB's ultra-heavy-duty robot delivering payloads up to 620 kg with reach up to 3.5 m, representing the pinnacle of large robot capability. With 16 variants and up to 30% energy savings, the IRB 7720 offers world-class performance for the most demanding heavy material handling, die casting, and welding operations. Engineered for maximum flexibility with shared modular components across the 7710/7720 family, it provides reliable, efficient automation for the world's heaviest manufacturing operations.

IRB 8700

The IRB 8700 is ABB's most capable general-purpose robot, engineered for the world's most demanding heavy-lift applications. With payloads up to 1000 kg and reach up to 4.2 m, the IRB 8700 moves 25% faster than competitors while maintaining exceptional reliability and ease of maintenance. Its compact design, simplified service procedures, and focus on low total cost of ownership make it the ultimate choice for heavy material handling, foundry operations, and other maximum-capacity automation needs.

GoFa Collaborative Robot

GoFa is ABB's revolutionary collaborative robot designed to work safely alongside human workers without protective barriers or fencing. Available in three payload variants (5, 10, 12 kg), GoFa delivers class-leading speed, precision, and safety with integrated torque sensors in each joint. The robot features GoFa Ultra Accuracy option with path accuracy down to 0.03 mm, making it perfect for high-precision applications like gluing, sealing, laser welding, and precision cutting. Its intuitive programming through graphical apps on the FlexPendant makes it ideal for first-time automation users while satisfying experienced programmers.

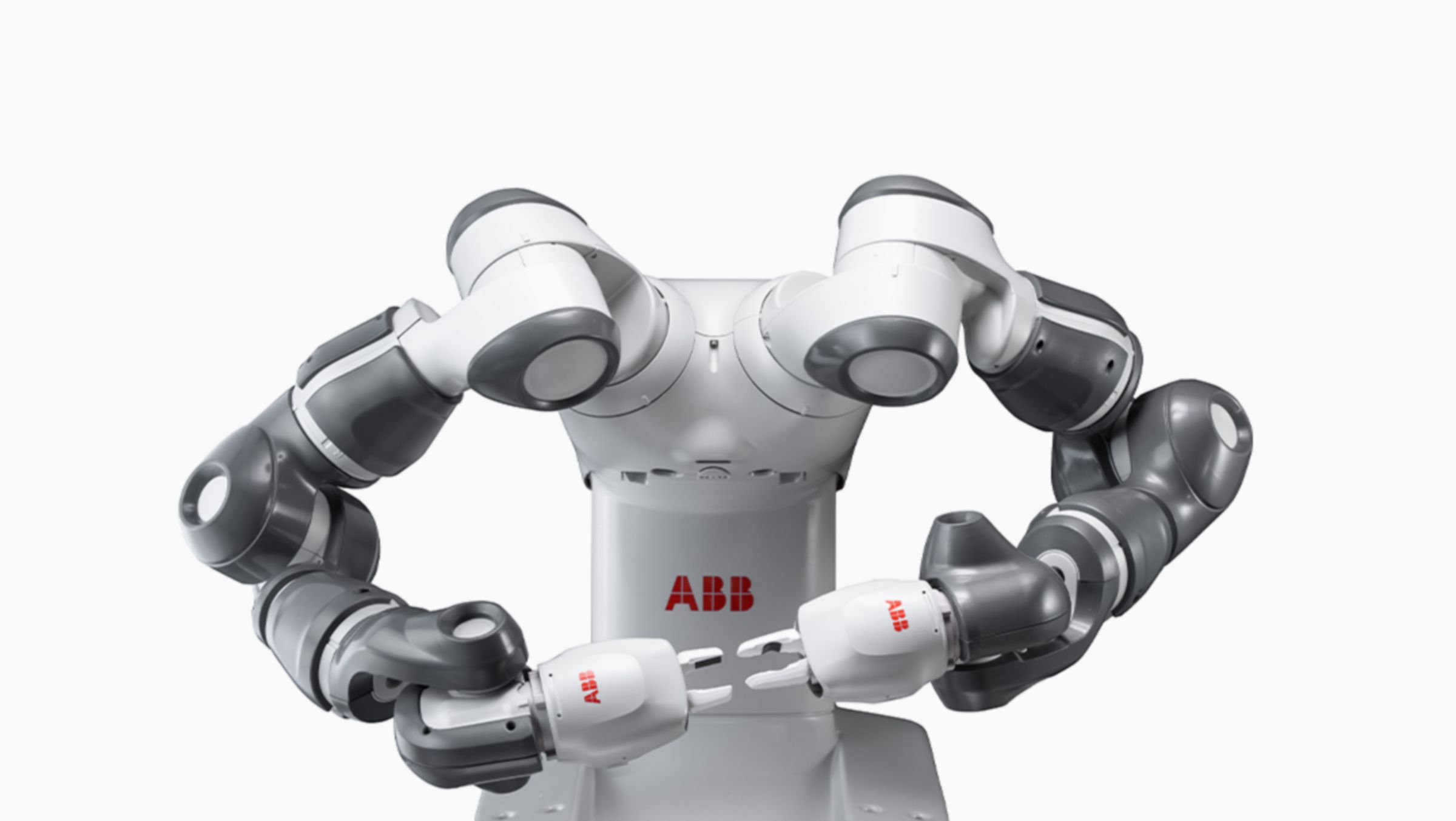

YuMi Dual-Arm (IRB 14000)

YuMi Dual-Arm (IRB 14000) is ABB's groundbreaking dual-arm collaborative robot designed for synchronized hand-to-hand work in electronics assembly, medical device manufacturing, and other precision assembly operations. With 0.5 kg payload per arm and 559 mm reach, YuMi delivers exceptional precision with 0.02 mm repeatability and 1.5 m/s maximum linear TCP speed. The 7-axis design per arm provides remarkable dexterity for complex assembly tasks while SafeMove collaborative features ensure safe operation alongside human workers.

YuMi Single-Arm (IRB 14050)

YuMi Single-Arm (IRB 14050) is a compact, lightweight collaborative robot designed for light assembly tasks, testing, and precision operations. With 0.5 kg payload, 559 mm reach, and 7 axes, it delivers the same dexterity as the dual-arm version in a compact single-arm configuration. The robot can be installed in any direction (vertical, horizontal, inverted) and features intuitive lead-through programming. Ideal for small parts assembly in electronics, watches, medical devices, and other precision industries where skill shortages are a challenge.

IRB 360 FlexPicker

The IRB 360 FlexPicker is the world's fastest industrial delta robot for picking and packing operations, holding the leader position for over 20 years. With payloads from 1 to 8 kg and reaches from 1130 to 1600 mm, the FlexPicker delivers outstanding motion performance with the shortest cycle times and exceptional accuracy. Up to 1200 picks per minute capability. Optimized for food, beverage, pharmaceutical, and electronics industries. IP69K validation for washdown environments and built-in PickMaster software support provide the most flexible picking solution for diverse manufacturing needs.

IRB 365 FlexPicker

The IRB 365 FlexPicker is a specialized 5-axis delta robot designed for high-speed reorientation and sophisticated picking tasks. With 1.5 kg payload and reach options of 800, 1100, or 1300 mm diameter, the IRB 365 delivers the fastest reorientation in its class at up to 120 picks per minute. The 5-axis design provides greater flexibility for Shelf Ready Packaging (SRP), parcel sorting, bottle unscrambling, and other complex picking operations where product orientation changes are essential.

IRB 390 FlexPacker

The IRB 390 FlexPacker is ABB's groundbreaking innovation in delta robot technology, delivering 35% faster speed and 45% larger working volume compared to predecessors. With payload capacity up to 15 kg and working diameter up to 1300 mm, the IRB 390 is designed for ultra-fast, high-payload picking and packing from high-speed systems running up to 100 m/min. Available in 4-axis (15 kg) and 5-axis (10 kg) variants, it handles complex Shelf Ready Packaging (SRP) and Retail Ready Packaging (RRP) tasks with ease.

IRB 910SC SCARA Robot

The IRB 910SC is a highly capable Selective Compliance Articulated Robot Arm (SCARA) designed to deliver fast, cost-effective, and accurate performance in confined spaces. With a compact tabletop-mountable design, the IRB 910SC is ideal for small parts assembly, material handling, component placement, and precision inspection. Available in three reach configurations (450, 550, 650 mm) with maximum payload of 6 kg, this robot combines rapid cycle times, high precision, and superior reliability with easy maintenance and customization.

IRB 660 Palletizing Robot

The IRB 660 is ABB's advanced 4-axis palletizing robot engineered for end-of-line operations where speed, precision, and reliability are paramount. With payload capacities up to 250 kg and reach of 3.15 meters, the IRB 660 brings efficiency and consistency to palletizing, depalletizing, and end-of-line material handling. This robust robot handles bags, boxes, crates, bottles, and various products across manufacturing, logistics, and food & beverage industries. Heavy-duty construction ensures dependable performance in demanding environments.

IRB 5500 FlexPainter

The IRB 5500 FlexPainter takes painting closer to perfection by integrating paint application equipment directly into the robot system. Combined with large work area, high acceleration, and painting speed, the result is the most efficient and flexible paint robot solution for automotive and industrial painting. Available in variants (5500-22 with 13 kg wrist payload, 5500-25 with rail mounting, 5500-27 with 7-axes), the FlexPainter reduces paint and solvent waste and enables multi-color painting with minimal changeover time.

IRB 5510 FlexPainter

The IRB 5510 FlexPainter is a highly flexible and accurate medium-sized paint robot for automotive small parts and general industrial painting. Offering the same advanced functions as the larger IRB 5500 in a small form factor with reduced footprint, the IRB 5510 provides shorter cycle times, process optimization, and advanced technologies for premium paint quality and system uptime. Ideal for small component painting, flaming treatment, and specialized coating applications.

RobotStudio Suite

RobotStudio Suite is ABB's comprehensive software platform for designing, programming, simulating, and commissioning robotic automation solutions. Built on the best-in-class ABB Virtual Controller technology, RobotStudio provides an exact digital replica of the physical production environment, allowing engineers to program and test installations offline without disrupting ongoing production. Available in desktop and cloud-based versions, RobotStudio supports advanced features including automatic collision-free path planning, virtual commissioning, augmented reality visualization, and real-time collaboration.

OmniCore Controller Family

OmniCore is ABB's revolutionary next-generation robot controller platform designed to power the widest range of robots and manipulators with class-leading motion control and energy efficiency. Available in five variants (E10, C30, C90XT, V250XT, V500), OmniCore controllers offer unified architecture, advanced motion control algorithms (TrueMove and QuickMove), built-in digital connectivity, and support for over 1000 hardware and software function expansions. Delivering up to 25% faster robot movements, 20% energy savings, and rapid commissioning from weeks to days.

AMR P603 (Flexley Mover)

The AMR P603 (Flexley Mover) is ABB's next-generation AI-powered autonomous mobile robot designed to revolutionize intralogistics and material handling. With powerful 1500 kg payload capacity, compact design for precise maneuvering in tight spaces, and advanced Visual SLAM navigation, the P603 combines intelligent autonomous navigation with modular versatility. Features include load center of gravity monitoring for stable transport, intelligent obstacle avoidance, and seamless integration with ABB's AMR Studio 4.0 software suite, enabling rapid deployment with no-code programming.