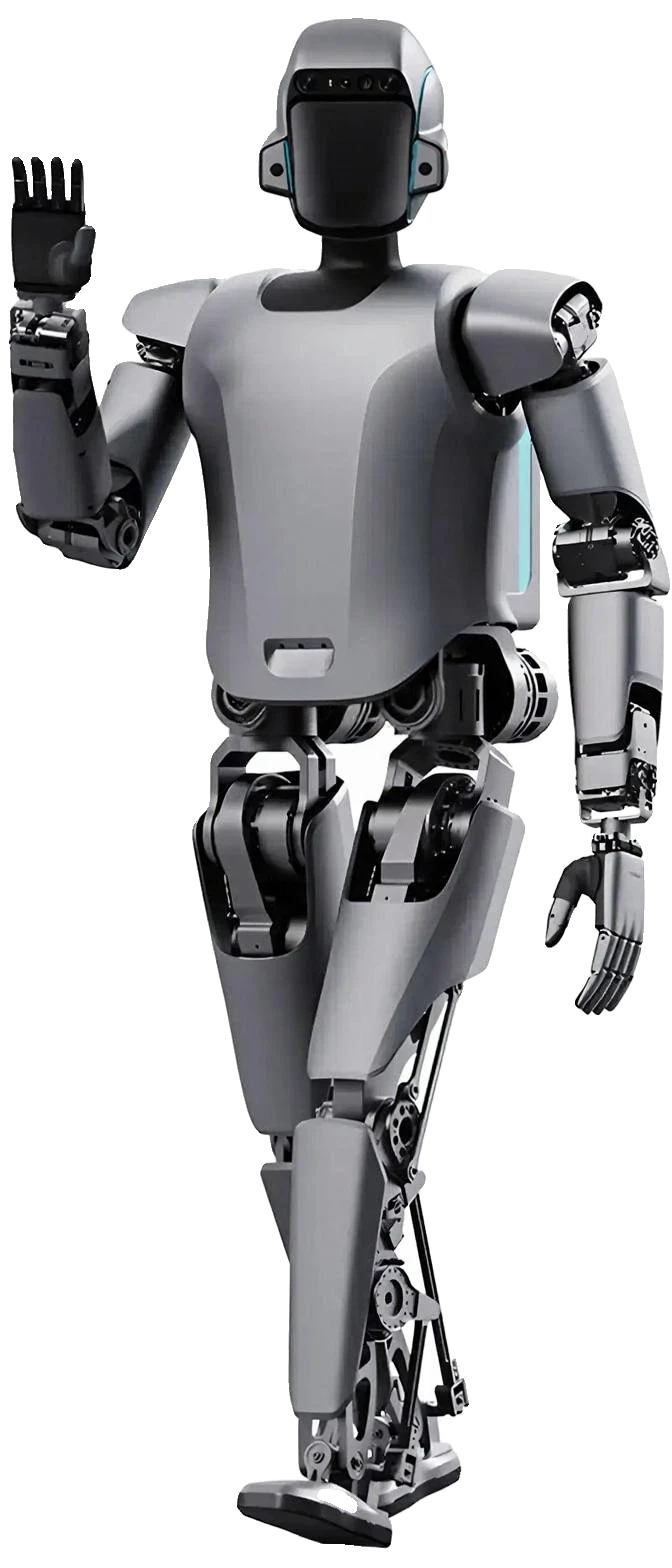

Walker S1

The UBTECH Walker S1 is an advanced humanoid robot designed to assist with tasks in both home and office environments. With its sophisticated navigation, movement, and interaction abilities, it can handle a wide range of activities, including walking, lifting, and responding to voice commands. Its sleek design and autonomous functions make it a versatile and intelligent companion.

Description

Key Features

Large Language Model Task Planning

Utilizes advanced LLM technology for intention understanding, task decomposition, and planning, enabling autonomous execution of complex industrial workflows with high generalization.

Semantic VSLAM Navigation

Two-stage semantic navigation fuses perception data with VSLAM for precise positioning and mapping in dynamic, poorly lit factory environments.

End-to-End Whole-Body Motion Control

Integrated perception-control framework with learning-based control delivers dexterous manipulation, stable walking, and handling of non-structured tasks under high loads.

Dexterous Hands with Tactile Sensing

3rd-gen hands feature 6 DOF per hand with array tactile pressure sensors for delicate gripping, sorting, and assembly.

Swarm Intelligence via BrainNet

Transformer sub-brain enables multi-robot collaboration, shared learning, and cross-field perception for efficient factory operations.

Multi-Task Industrial Applications

Supports parcel handling, quality inspection, screw tightening, part assembly, and logistics in collaboration with AMRs/AGVs.

Specifications

| Availability | Prototype |

|---|---|

| Nationality | China |

| Website | https://www.commercial.ubtrobot.com/ |

| Degrees Of Freedom, Overall | 41 |

| Height [Cm] | 172 |

| Manipulation Performance | 3 |

| Navigation Performance | 3 |

| Max Speed (Km/H) | 5 |

| Strength [Kg] | 3 |

| Weight [Kg] | 76 |

| Runtime Pr Charge (Hours) | 2 |

| Ingress Protection | IP67 (reported) |

| Connectivity | Supports multi-robot swarm via BrainNet |

| Motor Tech | High-performance servo joints (36+) |

| H.G Skill Score | 4 |

| Verified | Not verified |

| Walking Speed [Km/H] | 3 |

| Manufacturer | UBTECH Robotics |

| Height | 172 cm |

| Weight | 76 kg |

| Degrees Of Freedom (Overall) | 41 |

| Degrees Of Freedom (Hands) | 6 per hand (3rd-gen dexterous) |

| Max Walking Speed | 3-5 km/h |

| Payload Capacity | 16.3 kg dynamic (15-25 kg per arm) |

| Runtime Per Charge | 2 hours continuous |

| Sensors | RGBD visual sensors, array tactile pressure sensors on hands, position/speed/torque sensors |

| Processor | Intel i7 (reported) |

| Ai/Software | LLM for planning, Transformer sub-brain (BrainNet), Semantic VSLAM, end-to-end motion control |

| Hands | Self-developed 3rd-gen with tactile arrays |

| Battery | 48V lithium (series), capacity ~3-5 kWh estimated |

| Materials | Sleek silver alloy exterior (primary structural N/A) |

| Thermal Management | Joint cooling for high-load prolonged operation |

Curated Videos