Optimus Gen2

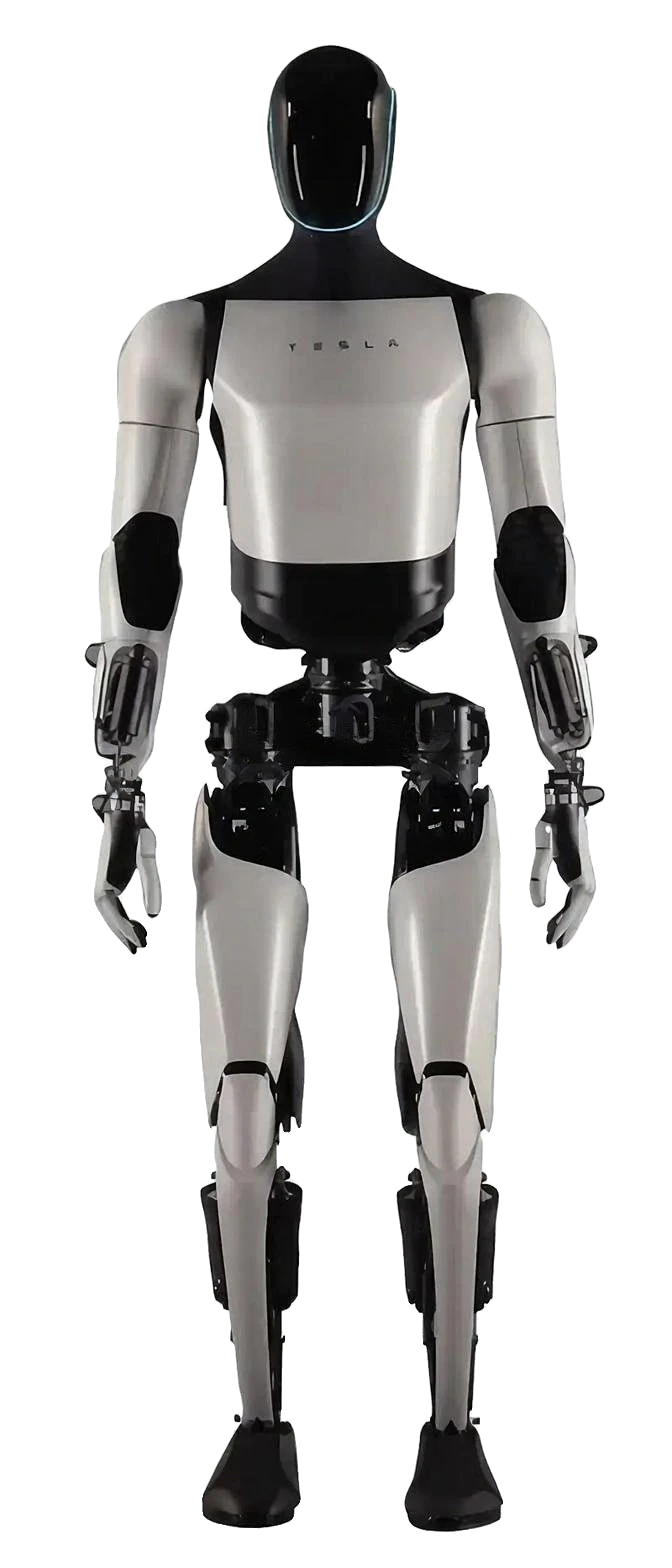

Tesla’s Optimus Gen 2 robot is a groundbreaking advancement in humanoid robotics, designed to handle unsafe, repetitive, or mundane tasks. With advanced actuators and sensors, it offers precise object manipulation and improved mobility, including a 30% increase in walking speed. Set for production by 2025, Optimus Gen 2 is poised to redefine automation across various industries, making it an invaluable asset for the future.

Description

Key Features

Dexterous Hands

11 degrees of freedom per hand with full tactile sensing, allowing precise handling of fragile objects like eggs, tools, and fabrics.

Enhanced Mobility

30% faster walking speed up to 8 km/h, with foot force/torque sensors and articulated toes for stable navigation on varied terrain.

Vision-Based AI

End-to-end neural networks for perception, planning, and control, trained on vast video datasets for autonomous task learning.

Custom Actuators

Tesla-designed high-precision actuators integrated with sensors and electronics for efficient, lightweight operation.

Improved Balance

Full-body control with IMUs and proprioceptive feedback enables crouching, recovery from falls, and dynamic movements.

Specifications

| Availability | Prototype |

|---|---|

| Nationality | US |

| Website | https://www.tesla.com/en_eu/AI |

| Degrees Of Freedom, Overall | 22 |

| Height [Cm] | 173 |

| Manipulation Performance | 3 |

| Navigation Performance | 3 |

| Max Speed (Km/H) | 8 |

| Strength [Kg] | 20 |

| Weight [Kg] | 56 |

| Runtime Pr Charge (Hours) | 1 |

| H.G Skill Score | 6 |

| Verified | Not verified |

| Walking Speed [Km/H] | 2 |

| Manufacturer | Tesla |

| Height | 173 cm |

| Weight | 56 kg |

| Degrees Of Freedom (Overall) | 28 |

| Degrees Of Freedom (Hands) | 11 per hand |

| Walking Speed | 8 km/h |

| Lift Capacity | 20 kg |

| Battery | 2.3 kWh (torso-mounted) |

| Runtime | 8 hours |

| Sensors | Multiple vision cameras (high-res, likely 5MP+), force/torque sensors (hands, feet), IMUs, tactile sensors on fingers |

| Processors | Tesla custom inference HW (HW4/HW5 equivalent, Dojo-trained models) |

| Actuators | Tesla-designed custom linear/rotary actuators with integrated electronics |

| Materials | Lightweight composites and alloys for structure |

| Neck | 2-DoF actuated |

| Hands | 11-DoF with tactile feedback |

| Feet | Force/torque sensing, articulated toes |

| Ai Latency | <100 ms glass-to-action |

| Ingress Protection | N/A (factory environment) |

| Operating System | Custom real-time Linux-based with NN inference |

Curated Videos