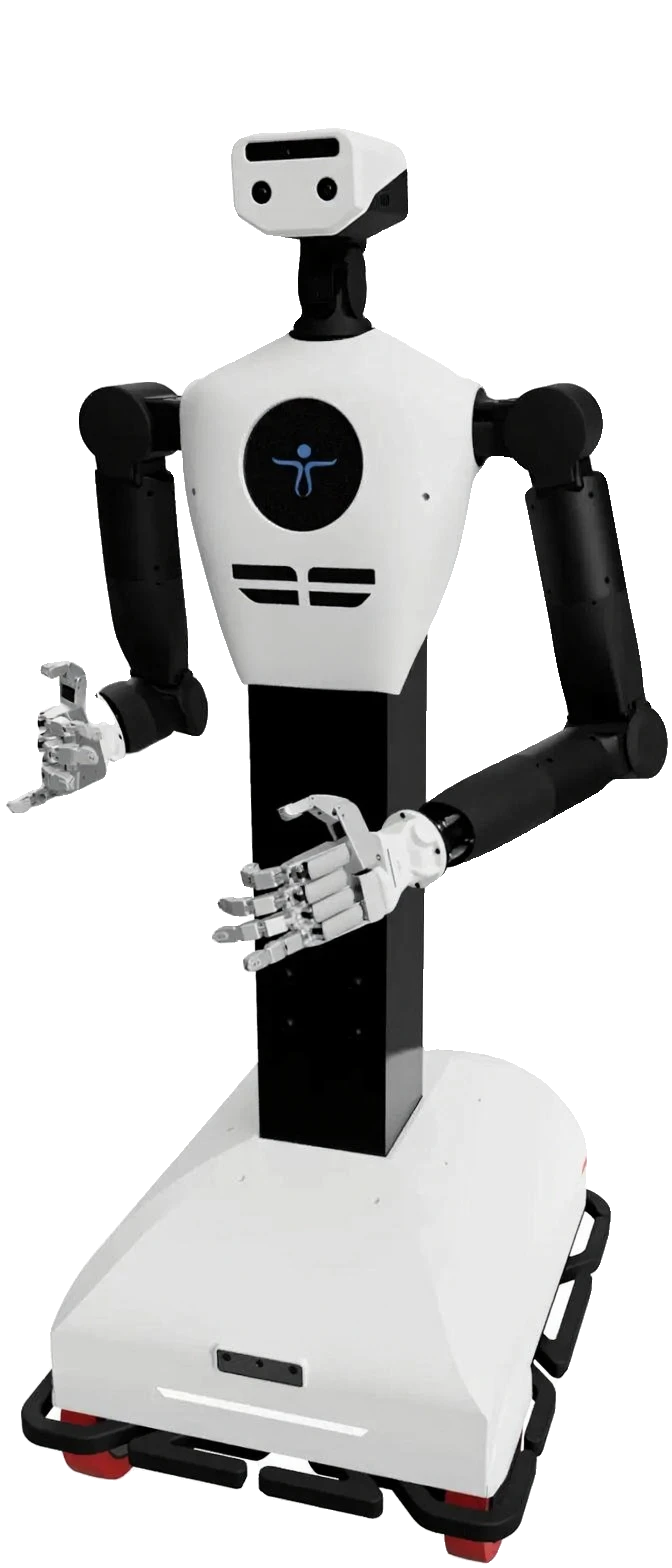

MH3

Mirsee Robotics’ MH3 is a humanoid robot engineered to augment skilled human labor across various industries. With advanced mobility, precision, and safety features, MH3 stands as a versatile solution for modern workforce challenges.

Description

Key Features

Teleoperation & Haptics

Immersive VR control with haptic feedback for precise remote manipulation in hazardous environments, bridging to AI autonomy.

Holonomic Wheeled Base

Mecanum wheels enable strafing, rotation, and high payload (300+ kg), prioritizing stability over legged locomotion.

Dexterous Manipulation

31 DoF overall, 6 DoF hands with 5 fingers, 30 kg/arm strength for tool use and dexterous tasks.

Hadron Vision System

NVIDIA Jetson-powered stereo cameras (12 MP) for 3D perception, sub-100 ms latency.

Extended Runtime

10-hour battery with wireless charging and hot-swappable modules for continuous operation.

Safety & Durability

Power-off brakes, IP54 rating, force-limited actuators for safe human collaboration.

Specifications

| Availability | In production |

|---|---|

| Nationality | Canada |

| Website | http://www.mirsee.com |

| Degrees Of Freedom, Overall | 31 |

| Degrees Of Freedom, Hands | 6 |

| Height [Cm] | 180 |

| Manipulation Performance | 2 |

| Navigation Performance | 2 |

| Max Speed (Km/H) | 5 |

| Strength [Kg] | 30 |

| Weight [Kg] | 125 |

| Runtime Pr Charge (Hours) | 10 |

| Safe With Humans | Yes |

| Cpu/Gpu | NVIDIA |

| Ingress Protection | IP54 |

| Camera Resolution | 12MP |

| Connectivity | Cellular, Satellite, WiFi |

| Operating System | ROS2 |

| Llm Integration | Various |

| Latency Glass To Action | Sub-100ms |

| Motor Tech | BLDC |

| Gear Tech | Harmonic & Planetary |

| Main Structural Material | Aluminum 6061 |

| Number Of Fingers | 5 |

| Main Market | Critical Infrastructure |

| Verified | Not verified |

| Manufacturer | Mirsee Robotics |

| Height | 180 cm |

| Weight | 125 kg |

| Dof Overall | 31 |

| Dof Hands | 6 per hand (5 fingers) |

| Payload | 30 kg per arm (27 kg combined) |

| Max Speed | 5 km/h |

| Runtime | 10 hours |

| Charging | Wireless, 2 hours full charge |

| Cpu Gpu | NVIDIA Jetson |

| Os | ROS2 |

| Llm Integration | Various |

| Latency | Sub-100 ms |

| Motors | BLDC |

| Gears | Harmonic & Planetary |

| Actuators | Hybrid hydrostatic (M-Drive patented tech) |

| Material | Aluminum 6061 |

| Ip Rating | IP54 |

| Cameras | 12 MP stereo (Hadron Vision System) |

| Connectivity | Cellular, Satellite, WiFi (2.4/5 GHz) |

| Vision Processor | NVIDIA Jetson with custom motherboard |

| Base | Mecanum wheeled holonomic, integrated suspension |

| Safety | Power-off brakes, human-safe force limits |

| Battery | Modular hot-swappable, scalable output |

Curated Videos