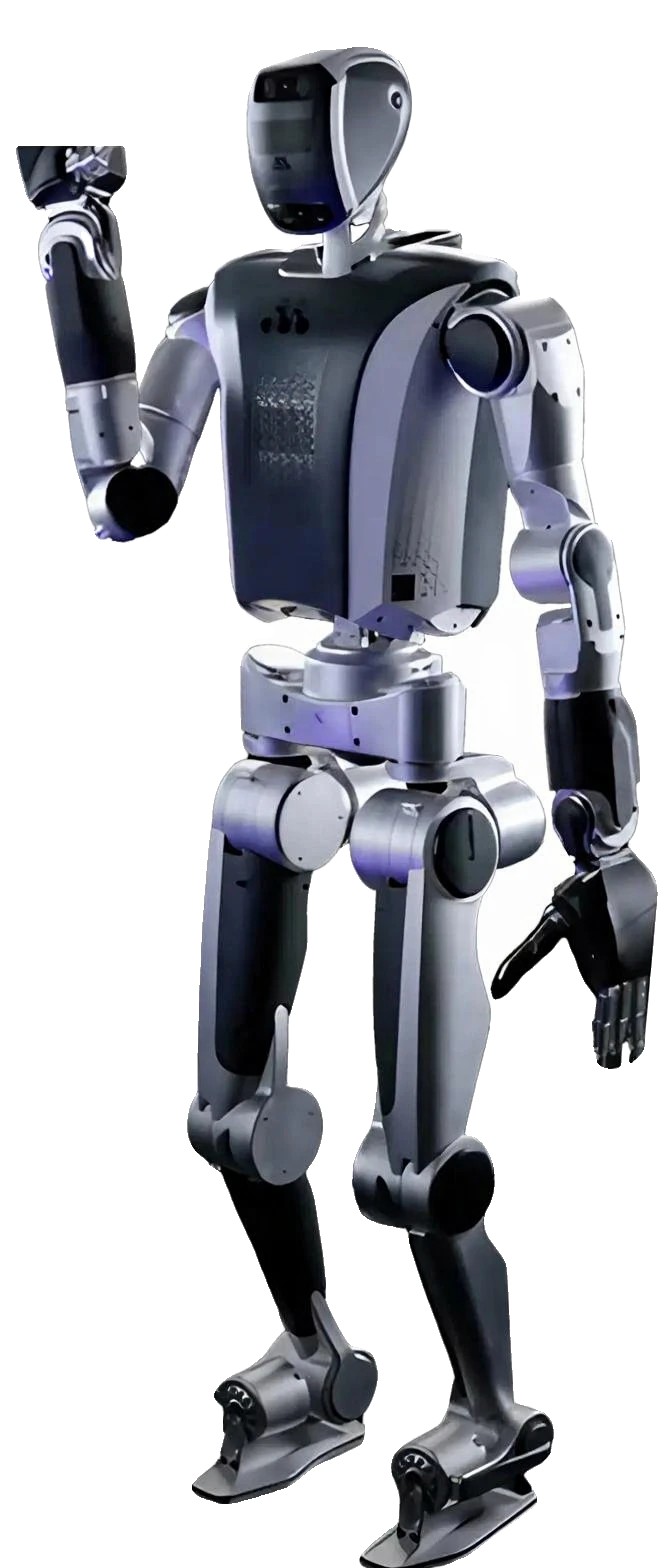

MenteeBot V3

Menteebot V3 is a full-size humanoid robot designed for heavy lifting and warehouse automation. Standing 1.75 m tall, it can handle loads up to 25 kg with smooth, human-like movement powered by AI-driven control and real-time 3D vision. Using advanced perception, reinforcement learning, and an onboard language model, it navigates complex environments, adapts to tasks, and follows spoken or written commands. Ideal for logistics, it autonomously retrieves, transports, and organizes goods, reducing strain on human workers. With a quick-swap battery for continuous operation, Menteebot V3 enhances efficiency and safety in industrial settings.

Description

Key Features

Heavy Payload Capacity

Lifts up to 25 kg using custom high-power-density actuators, ideal for warehouse logistics and reducing human strain in repetitive tasks.

360° Vision System

Five cameras including fisheye lenses provide full situational awareness, enabling real-time 3D mapping with NeRF/3DGS for navigation in cluttered environments.

Modular AI Architecture

Combines LLM for task planning, RL policies at 40 Hz for control, and advanced perception for autonomous operation without constant cloud dependency.

Hot-Swappable Battery

Supports 3-4 hours runtime per charge with quick swaps for continuous 24/7 operation in industrial settings.

Rapid Task Learning

Learns new skills from single demonstrations via imitation RL and Sim2Real, adapting in hours without expert intervention.

Robust Hands

Redesigned grippers with 30 N pinch force per finger offer precise manipulation, impact resistance, and dexterity for rigid objects.

Specifications

| Availability | Prototype |

|---|---|

| Nationality | Israel |

| Website | http://N/A |

| Degrees Of Freedom, Overall | 55 |

| Height [Cm] | 175 |

| Manipulation Performance | 2 |

| Navigation Performance | 2 |

| Max Speed (Km/H) | 3 |

| Strength [Kg] | 25 |

| Weight [Kg] | 65 |

| Runtime Pr Charge (Hours) | 4 |

| H.G Skill Score | 4 |

| Verified | Not verified |

| Manufacturer | Mentee Robotics |

| Height | 175 cm |

| Weight | 65-70 kg |

| Payload | 25 kg |

| Max Speed | 1.5 m/s (5.4 km/h) |

| Dof Overall | 40-55 |

| Processors | Dual NVIDIA Jetson Orin AGX |

| Vision | 360° via 5 cameras (stereo front, fisheye sides, rear); NeRF/3DGS mapping, OWLv2 detection |

| Hands | Pinch force 30 N per finger; redesigned for impact resistance |

| Actuators | Custom high-torque, 3x power density |

| Battery | Hot-swappable, 3-4 hours runtime (180+ min), voltage/kWh N/A |

| Control Frequency | 40 Hz RL policies |

| Sensors | IMUs per joint, depth sensors, stereo cameras |

| Materials | Robust ergonomic frame (specifics N/A) |

| Connectivity | Wi-Fi (2.4/5 GHz), USB |

| Os | Proprietary full-stack AI |

Curated Videos