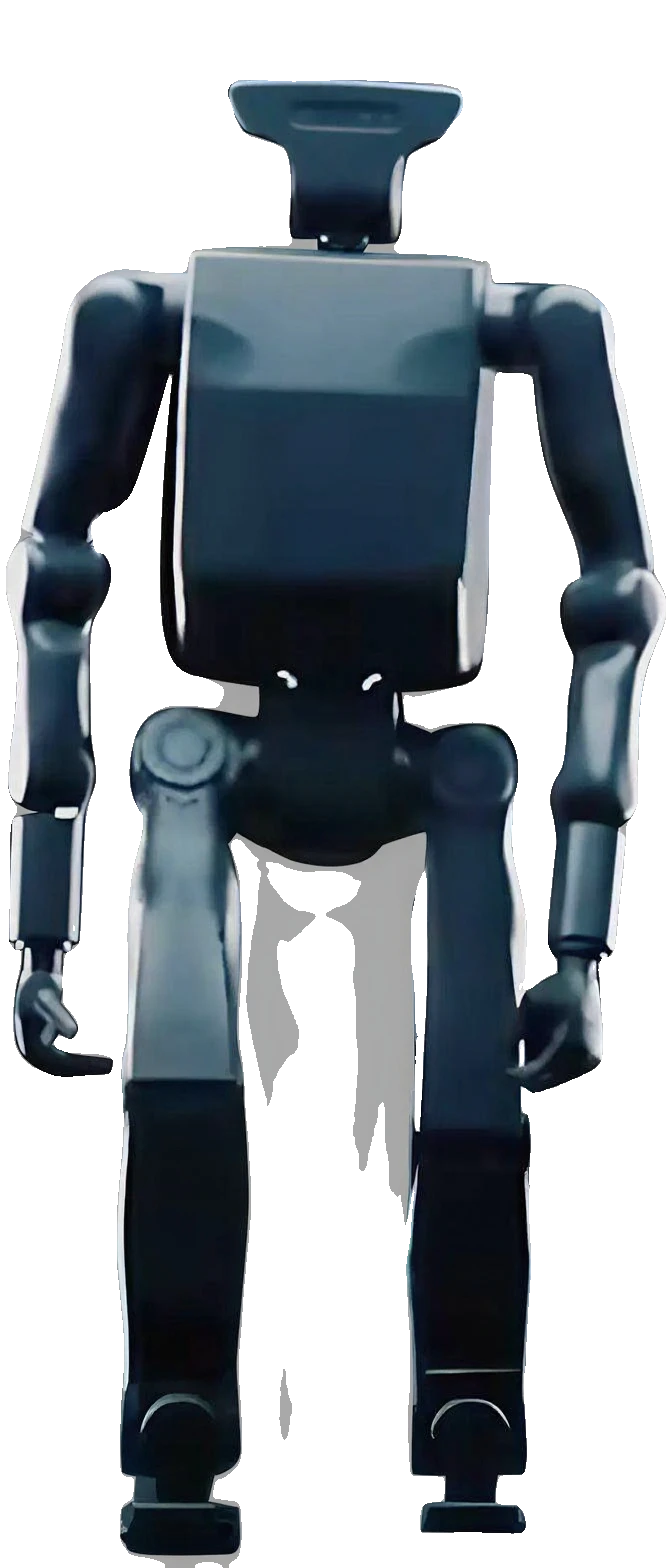

Jaka K1

The JAKA K1 is a flexible humanoid robot from JAKA Robotics, designed for automation in industries like manufacturing, logistics, and customer service. With a compact, modular design and intelligent AI, it recognizes objects, interprets tasks, and safely interacts with humans. Equipped with depth cameras and motion sensors, it navigates dynamic environments, performing precise actions. Lightweight and energy-efficient, the K1 is built for long-term use. JAKA Robotics aims for it to enhance productivity and safety, bridging technology with human-centered applications.

Description

Key Features

Modular Component System

Provides swappable brain, dual arms, force/vision sensors, and dexterous hands for rapid humanoid R&D and scenario building.

High-DOF Arms

14 DOF total (7 per arm) with 633 mm reach and 6 kg payload, enabling precise manipulation in complex tasks.

6D Force Control

Real-time sensing and reaction to multi-directional forces for safe human interaction and delicate handling.

Advanced Perception

Depth cameras, touch sensors, and motion detectors for object recognition and dynamic environment navigation.

AI Learning Capabilities

Adaptive AI for task interpretation, real-time decision-making, and continuous learning in unstructured settings.

Specifications

| Availability | Prototype |

|---|---|

| Nationality | China |

| Website | http://N/A |

| Degrees Of Freedom, Overall | 18 |

| Height [Cm] | 165 |

| Manipulation Performance | 2 |

| Navigation Performance | 2 |

| Max Speed (Km/H) | 4 |

| Strength [Kg] | 8 |

| Weight [Kg] | 40 |

| Runtime Pr Charge (Hours) | 3 |

| H.G Skill Score | 4 |

| Verified | Not verified |

| Walking Speed [Km/H] | 3.5 |

| Manufacturer | JAKA Robotics |

| Height Cm | 180 |

| Weight Kg | 40 |

| Dof Overall | 29 joints (14 in arms) |

| Dof Arms | 14 (7 per arm) |

| Reach Mm | 633 per arm |

| Payload Kg | 6 peak per arm |

| Arm Weight Kg | 5.5 per arm |

| Walking Speed Kmh | 3.5 |

| Max Speed Kmh | 4 |

| Runtime Hours | 3 |

| Strength Kg | 8 |

| Sensors | Depth cameras, touch sensors, motion sensors, 6D force control |

| Control | 1 kHz CAN-FD |

| Ai Capabilities | Object recognition, adaptive learning, real-time force/vision integration |

| Materials | Lightweight modular frame (details N/A) |

| Battery | N/A kWh/voltage (3h runtime) |

Curated Videos