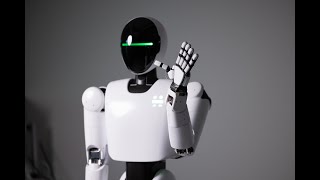

Friday

Friday is Holiday Robotics’ dexterous humanoid for real-world work, pairing a 63-DoF body and tactile 20-DoF hands with a fast wheeled base, autonomous/teleop control, and hot-swap power for research, logistics, and human-interactive tasks.

Description

Key Features

Ultra-Dexterous Tactile Hands

20-DoF hands (500g each) with full-palm magnetic tactile sensors detecting 0.05N forces at 1900Hz for precise, compliant manipulation of delicate objects.

High-Speed Wheeled Mobility

Differential drive base (66kg) enables 1.9 m/s speeds, stability for industrial floors, and 24/7 operation with hot-swappable batteries.

VLS AI Framework

Vision-Language-Skill system with pre-verified skills trained in Holiday Sim simulator, ensuring safe, reliable task execution without black-box models.

Back-Drivable Joints

All 63 DoF use BLDC motors with QDD gearing for safe human interaction, low impedance, and precise force control.

Ground-Reaching Torso

5-DoF torso allows access to floor-level objects, combined with 7-DoF arms for human-scale workspace.

Specifications

| Availability | Prototype |

|---|---|

| Website | http://holiday-robotics.com |

| Degrees Of Freedom, Overall | 63 |

| Degrees Of Freedom, Hands | 20 |

| Height [Cm] | 173 |

| Manipulation Performance | 2 |

| Navigation Performance | 1 |

| Max Speed (Km/H) | 6.84 |

| Strength [Kg] | 20 |

| Weight [Kg] | 115 |

| Runtime Pr Charge (Hours) | 4 |

| Safe With Humans | Yes |

| Cpu/Gpu | NVIDIA Jetson Orin |

| Ingress Protection | No |

| Connectivity | Wi‑Fi |

| Operating System | Linux |

| Llm Integration | No |

| Latency Glass To Action | 0.2s |

| Motor Tech | BLDC |

| Gear Tech | QDD |

| Main Structural Material | Aluminum |

| Number Of Fingers | 10 |

| Main Market | Manufacturing |

| Verified | Not verified |

| Walking Speed [Km/H] | 6.84 |

| Manufacturer | Holiday Robotics |

| Height | 176 cm |

| Weight | 115 kg (base 66 kg, arms 5 kg each, upper body ~24 kg torso/waist +15 kg) |

| Dof Overall | 63 |

| Dof Hands | 20 per hand |

| Dof Arms | 7 per arm |

| Dof Torso | 5 |

| Max Speed | 1.9 m/s (6.84 km/h) |

| Payload Arm | 5 kg end-effector, 20 kg proximal |

| Hand Weight | 0.5 kg |

| Tactile Sensors | Full-palm magnetic sensors, 0.05 N resolution, 1900 Hz refresh, ~$21 per sensor |

| Cpu Gpu | NVIDIA Jetson Orin |

| Motors | BLDC with QDD gearing, back-drivable |

| Structural Material | Aluminum |

| Battery | Hot-swappable, 4 hours runtime per charge (kWh unspecified) |

| Os | Linux |

| Connectivity | Wi-Fi |

| Latency | 0.2 s perception-to-action |

| Mobility | Differential wheeled base |

| Sensors | Tactile/force (hands), cameras (resolution N/A), IMU/proprioception implied |

| Ingress Protection | None |

| Price Estimate | $70,000 - $200,000 (prototype/variant dependent) |

Curated Videos