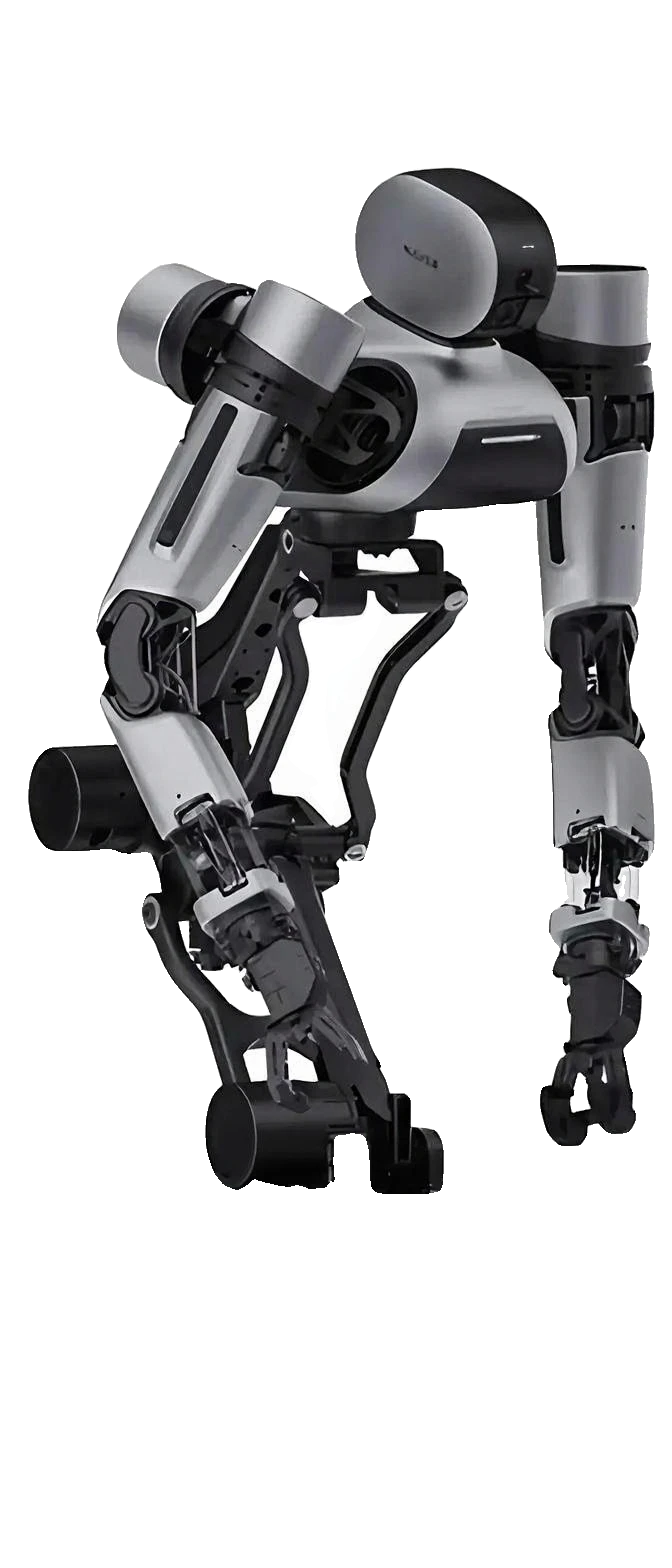

Ambidex

Ambidex by Naver Labs is a versatile, lightweight robot designed for precision and safe human collaboration. Its cable-driven technology, advanced AI, and adaptability make it an innovative solution for industries requiring delicate and efficient robotic assistance.

Description

Key Features

Cable-Driven Lightweight Arms

Each 2.6 kg arm with 7 DOF uses base-mounted actuators and wires for low inertia, enabling 5 m/s speeds and 3 kg payloads with human-safe compliance.

Haptic Bilateral Teleoperation

7 DOF haptic devices provide force/position feedback for intuitive teaching, capturing physical intelligence data for AI learning.

Task Learning AI

Proprietary RL and deep learning from haptic demos enable autonomous execution of complex tasks like furniture assembly and sports.

5G Brainless Control

Cloud computing via ultra-low latency 5G offloads processing, supports remote operation, and facilitates multi-robot data sharing.

Safe Human Interaction

Force-controlled joints and compliant design allow collision-free collaboration, demonstrated in high-fives, hugs, and shared workspaces.

Modular Upper Body

186 cm height with waist, sensor head for perception, and adaptable grippers for expanded dexterity in real-world testbeds.

Specifications

| Availability | In production |

|---|---|

| Nationality | South Korea |

| Website | https://www.naverlabs.com/ambidex |

| Degrees Of Freedom, Overall | 47 |

| Height [Cm] | 186 |

| Manipulation Performance | 2 |

| Navigation Performance | 2 |

| Max Speed (Km/H) | 3.6 |

| Strength [Kg] | 6 |

| Runtime Pr Charge (Hours) | 8 |

| H.G Skill Score | 4 |

| Verified | Not verified |

| Manufacturer | Naver Labs |

| Dof Per Arm | 7 |

| Total Dof Arms | 14 |

| Overall Dof | 47 (estimated with waist/head/grippers) |

| Arm Weight | 2.6 kg each |

| Payload | 3 kg per arm (up to 5 kg in variants) |

| Max Tip Speed | 5 m/s |

| Height | 186 cm |

| Runtime | 8 hours |

| Actuators | Cable-driven with base/shoulder motors (brushless, torque up to 42 Nm continuous in LIMS3) |

| Sensors | Force/torque sensors in joints/cables, position encoders, vision cameras in sensor head, haptic feedback sensors |

| Processors | Onboard for real-time control; cloud (5G MEC) for AI/ML (no specific models disclosed) |

| Connectivity | 5G (ultra-low latency), Wi-Fi 2.4/5 GHz, USB |

| Materials | Lightweight composites/metals; black frame for sensors, minimal covers for assembly |

| Grippers | BLT Gripper (adaptable grasping) |

| Control Modes | Haptic teleop, impedance control, RL-based autonomy |

| Battery | N/A (proprietary, supports 8-hour runtime) |

| Os Software | Proprietary closed-source with haptic/RL modules |

| Other | Waist mechanism for workspace expansion; 5G brainless architecture |

Curated Videos